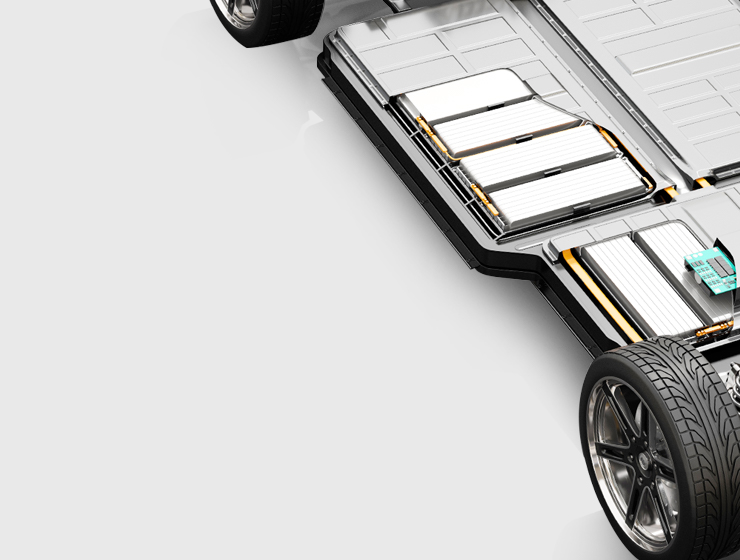

Copper busbars offer high creep resistance, excellent conductivity, and thermal dissipation, while aluminum busbars provide lightweight advantages with cost efficiency. Both support the trends toward lightweight, integrated, and precision installation in new energy vehicles. Their core applications cover three major systems: battery, motor, and electronic control.

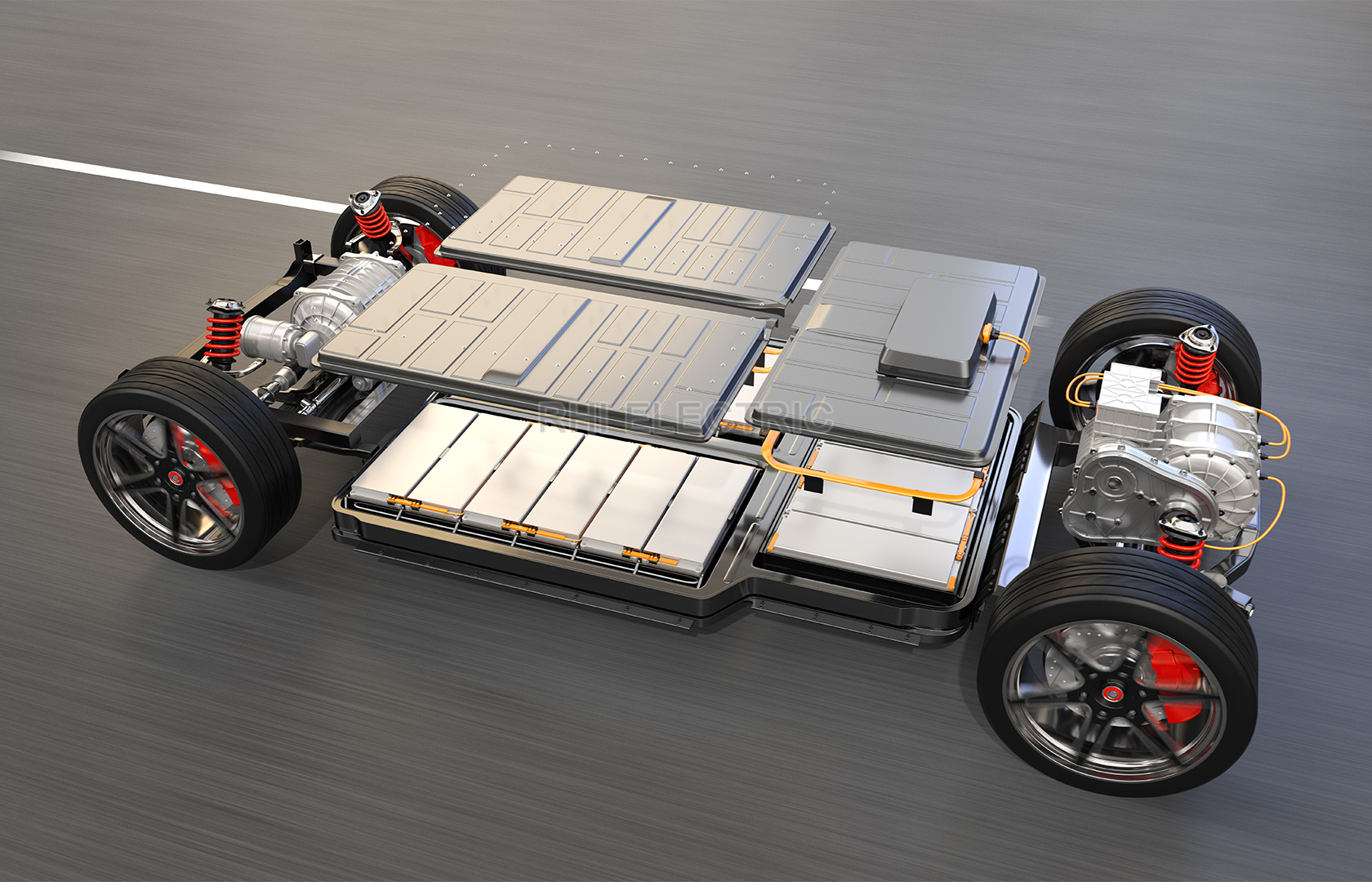

Electric Vehicle Powertrain Systems

Custom busbars are key connectors. Foil flexible connectors link individual cells, compensating for displacement and vibration to ensure reliability. Extruded, dip-coated, or powder-coated copper busbars meet high-power and high-current needs in modules and packs. Aluminum busbars are used in low-voltage circuits of the Battery Management System (BMS). Optimized layout and insulation also support thermal management, maintaining conductivity in high-temperature environments.

Overmolded copper busbars connect windings inside Permanent Magnet Synchronous Motors (PMSMs). Their custom design, precision molding, and high-performance insulation suit high-frequency vibration and high-voltage conditions, serving as core electrical components.

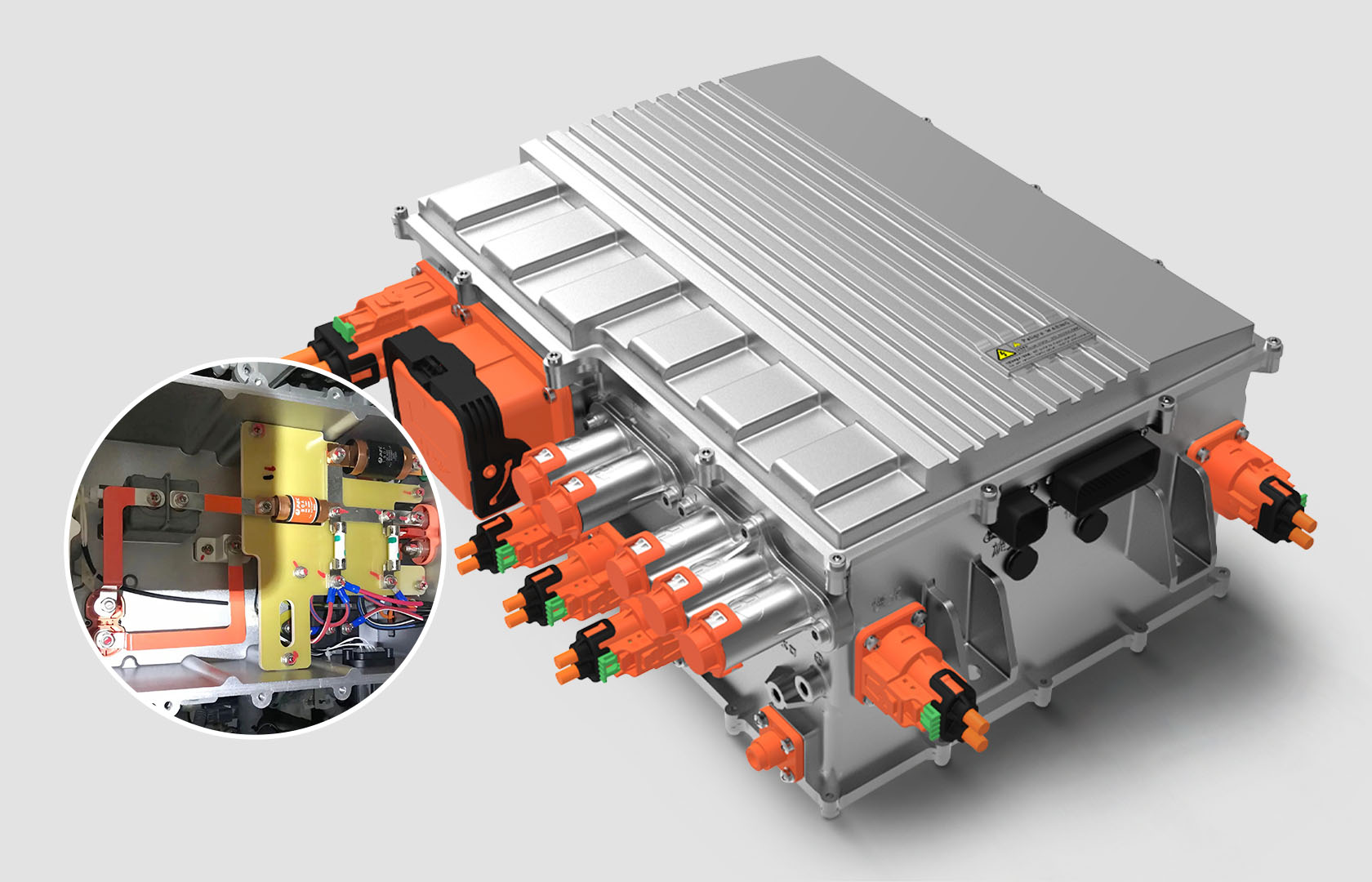

Electronic Control System

Dip-coated, powder-coated, and overmolded copper busbars meet high-precision, integrated installation needs. They carry high current in components like the Power Distribution Unit (PDU), Motor Control Unit (MCU), On-Board Charger (OBC), and DC-DC converter, efficiently distributing high-voltage power from the battery system. These busbars provide stable transmission for power conversion—such as AC/DC in OBCs, DC/DC voltage step-down, and DC/AC in MCUs—ensuring precise power delivery to vehicle systems.

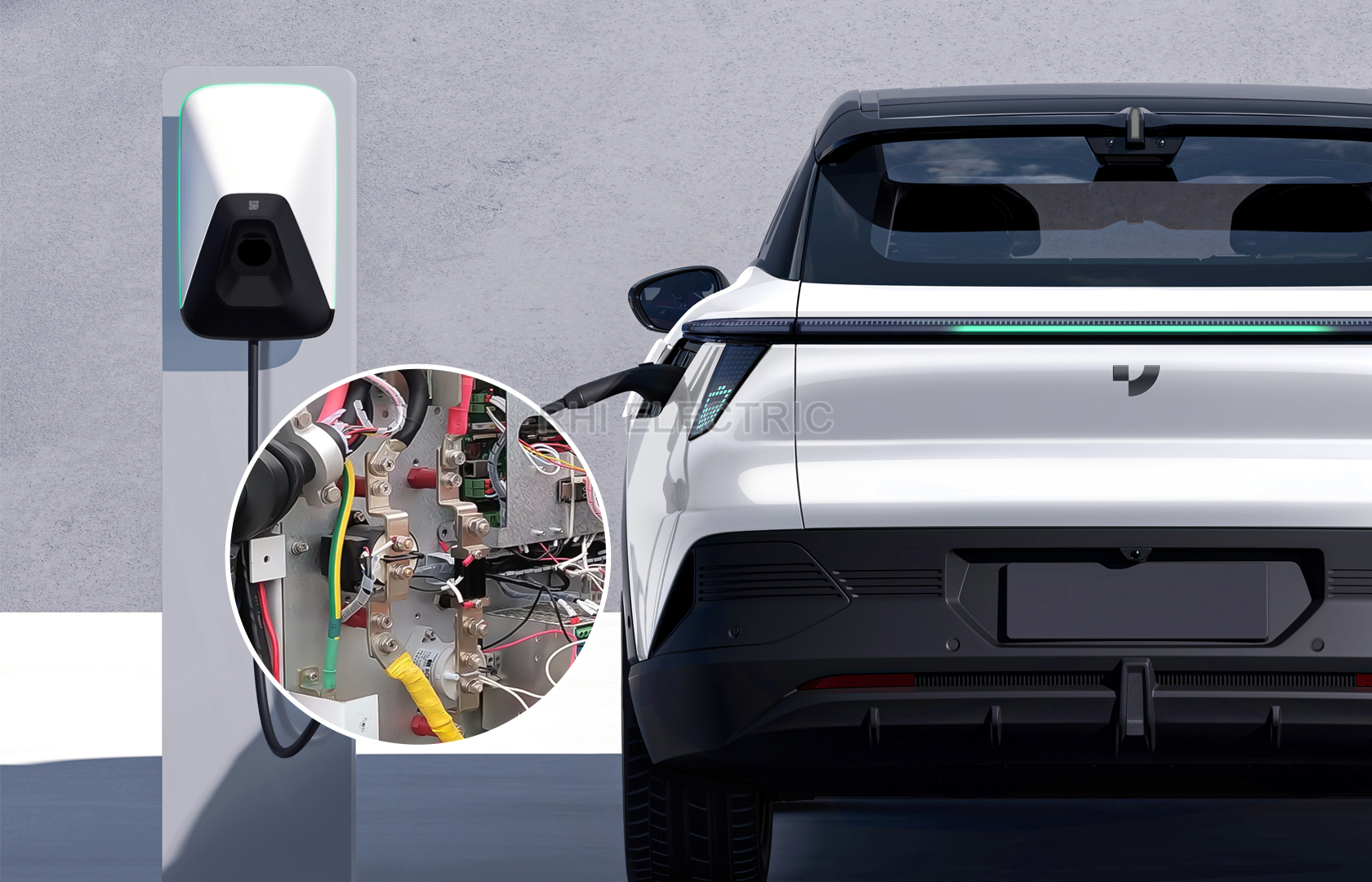

EV Charging Piles

Busbars in EV charging piles are primarily involved in power transmission and distribution:

- High-Power Transmission: Copper busbars, with their excellent conductivity, are suitable for high-power charging piles requiring large current transmission. Aluminium busbars offer advantages in scenarios where structural weight reduction is crucial.

- Simplified Structure: The use of busbars reduces the complexity of internal wiring in charging stations, optimizing internal structure design, making equipment more compact, and easier to install and maintain.

- Thermal Management: The thermal conductivity of copper and aluminium busbars aids in effective heat dissipation, ensuring the stability and safety of charging stations under high-load conditions.

Advantages: Electrical busbars enhance the overall efficiency and reliability of charging piles, supporting continuous operation under high load and ensuring safety during the charging process.