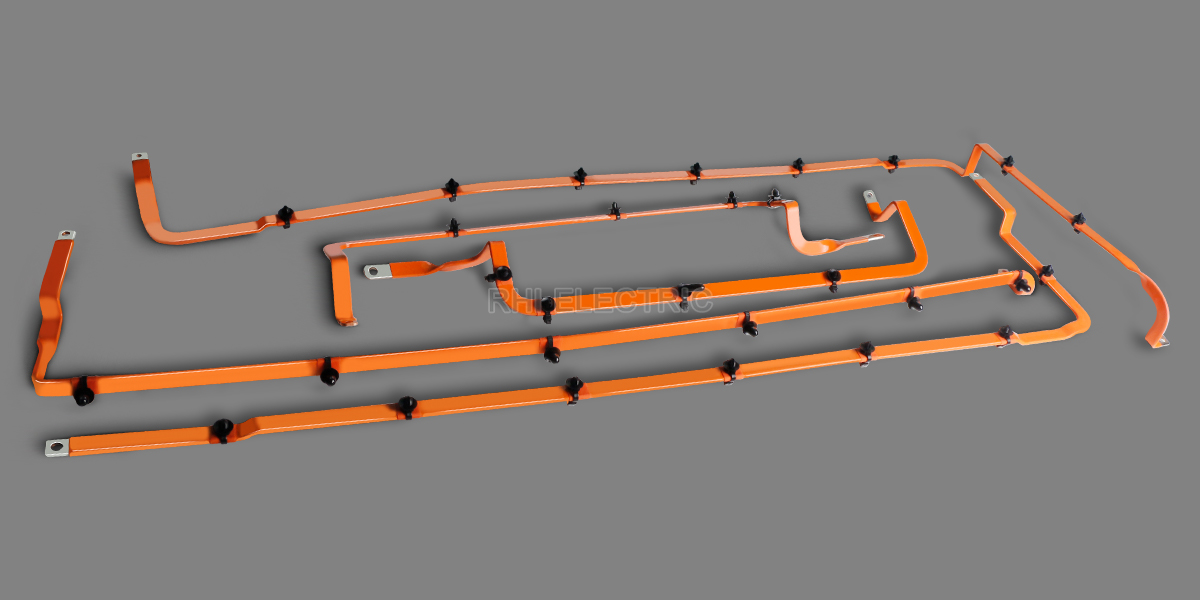

Rigid Copper Busbar Solutions by RHI

Discover high-performance Rigid Copper Busbars engineered for good electrical conductivity, durability, and efficiency. At RHI, we combine advanced manufacturing techniques with stringent quality controls to deliver products that excel in demanding applications across multiple industries.

Product Advantages & Features

-

Exceptional Electrical Conductivity:

Manufactured from high-purity copper, our busbars ensure minimal resistance and maximum current carrying capacity, delivering efficient power distribution. -

Robust Construction & Durability:

Designed to withstand harsh environments, our rigid copper busbars offer exceptional mechanical strength and thermal stability, ensuring longevity and reliability. -

Precision Engineering:

With state-of-the-art manufacturing processes, each busbar is produced with tight tolerances and uniform dimensions, making them ideal for critical applications. -

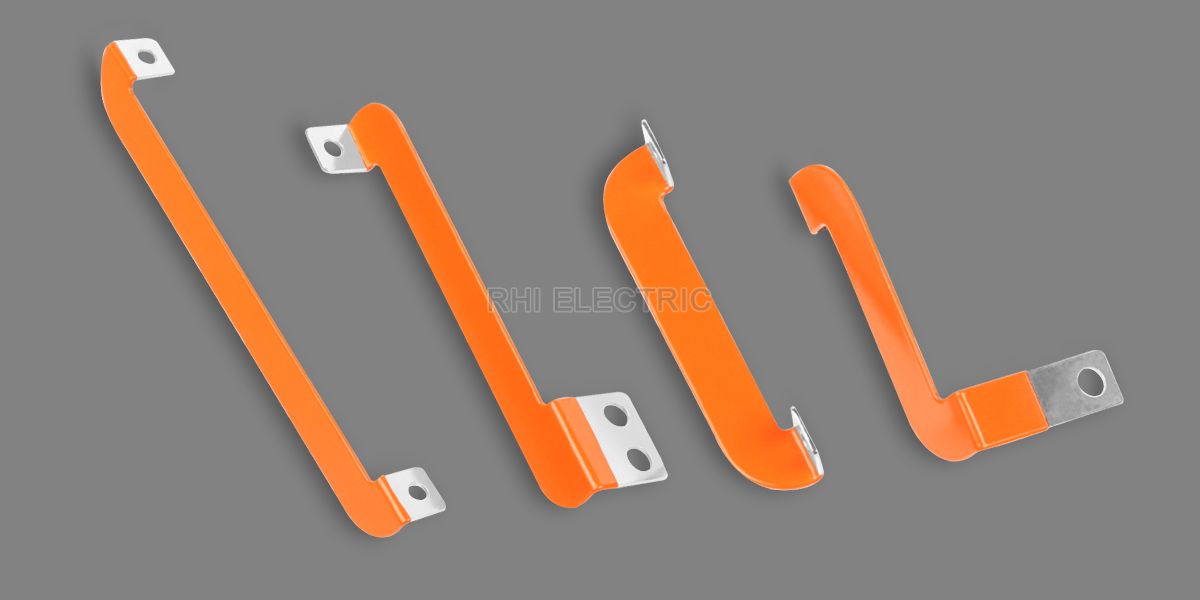

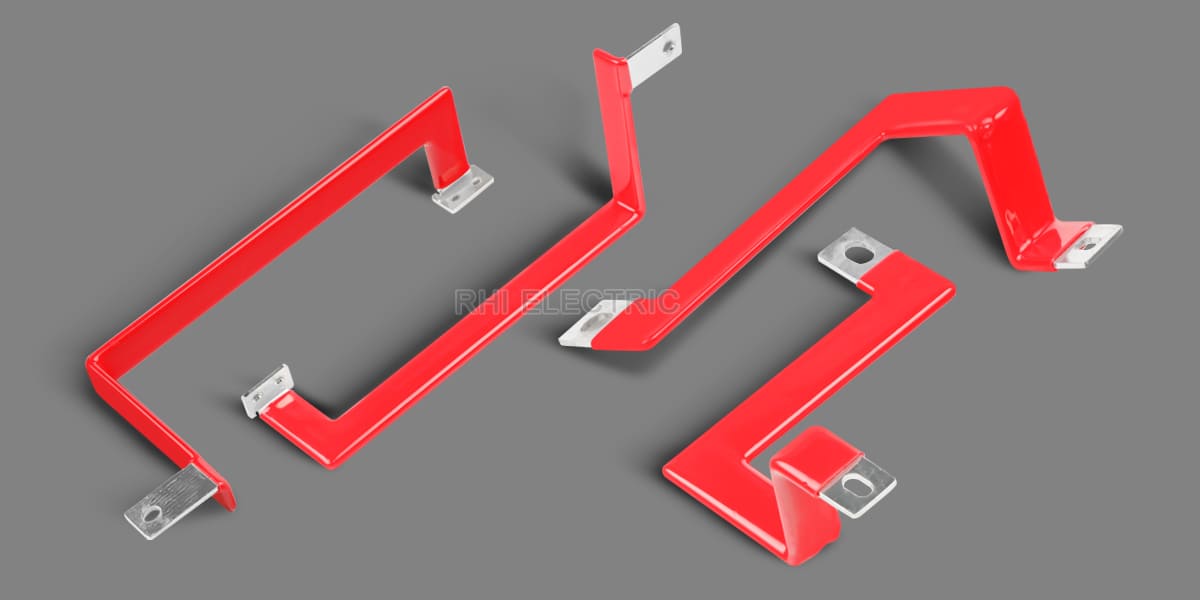

Customizable Solutions:

RHI provides flexible design options to match specific project requirements—from varying sizes and shapes to specialized coatings—ensuring seamless integration into your systems. -

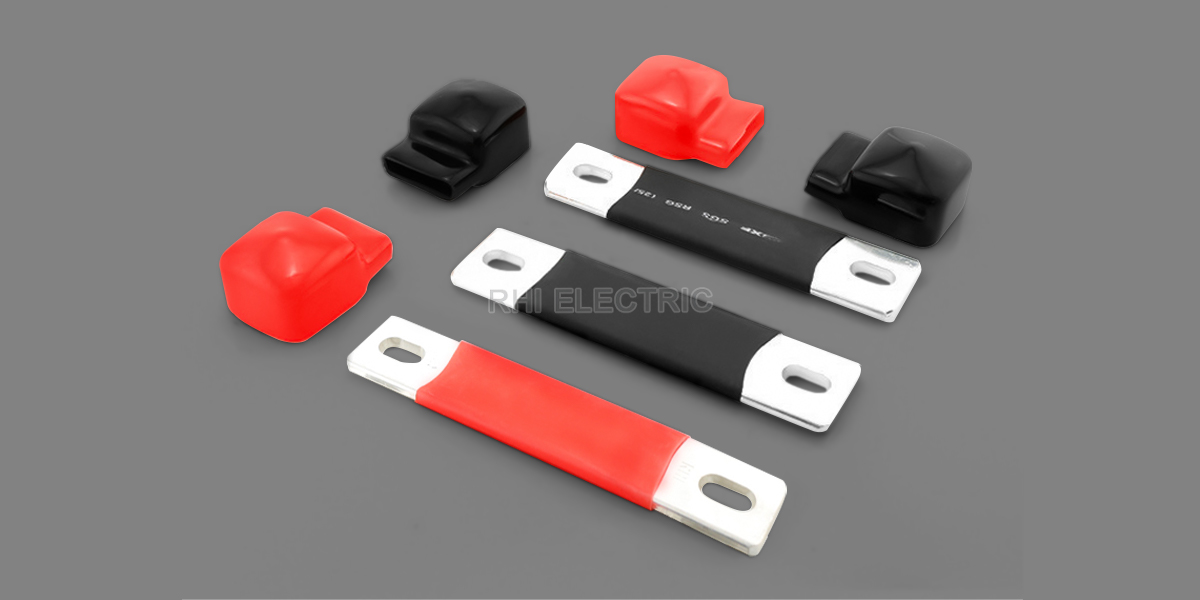

Enhanced Safety:

Optimized for high current applications, our busbars feature superior heat dissipation and insulation compatibility, reducing the risk of overheating and electrical failures.

Product Parameters & Specifications

Our rigid copper busbars are available in a variety of specifications tailored to meet diverse industry needs. Key parameters include:

- Material: High-purity copper (typically 99.95% pure)

- Conductivity: ≥98% IACS (International Annealed Copper Standard)

- Dimensions:

- Width: Customizable from 20 mm to 200 mm

- Thickness: Ranging from 2 mm to 20 mm

- Length: Standard sizes available, with custom lengths on request

- Current Rating: Designed for high current applications, capable of handling thousands of amperes

- Temperature Range: Suitable for operation in environments from -50°C to +125°C

- Surface Treatment: Options include tin-plating or nickel-plating for enhanced corrosion resistance

- Compliance: Meets international standards for electrical performance and safety

Application Scenarios

Rigid copper busbars are integral components in a wide range of electrical and industrial applications:

-

Power Distribution Panels:

Ideal for high-power switchgear, substations, and electrical distribution boards, ensuring reliable current flow in demanding conditions. -

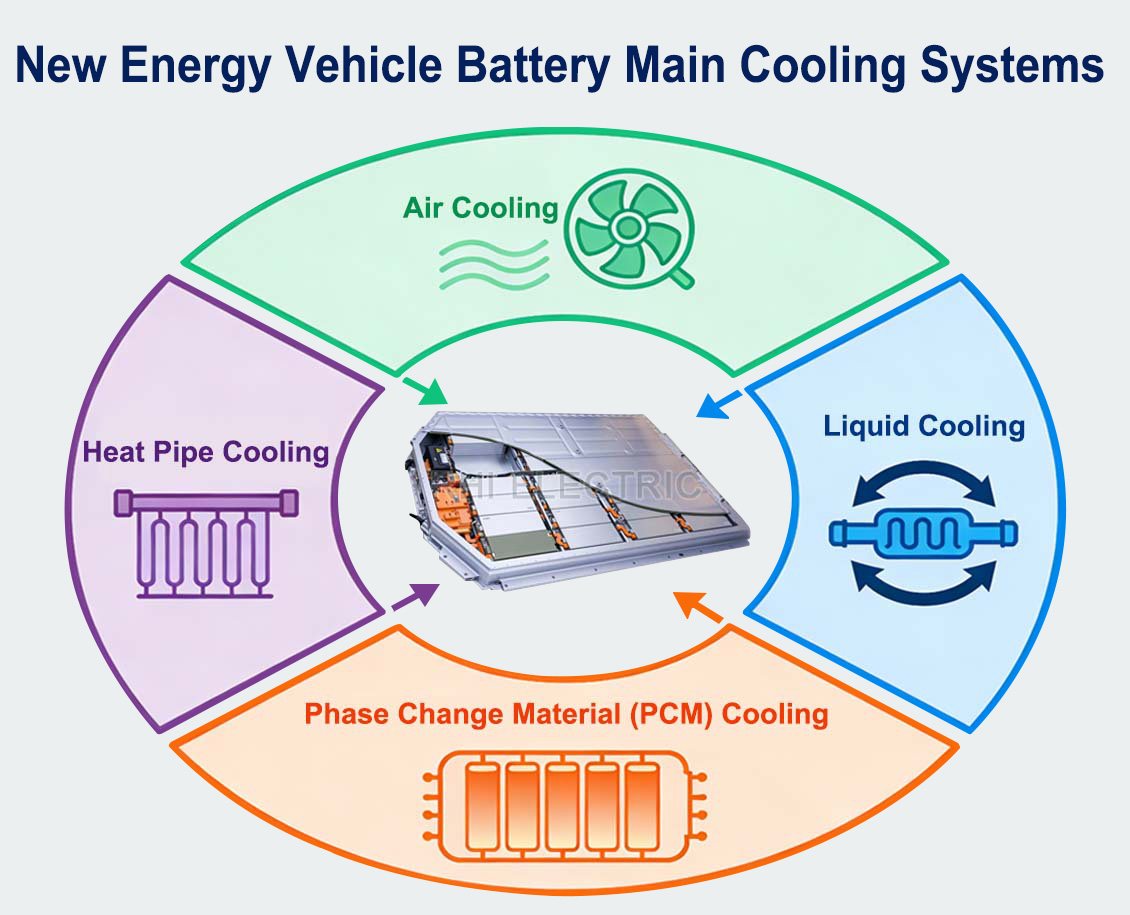

Renewable Energy Systems:

Enhances the efficiency and durability of solar inverters, wind turbines, and battery storage systems by providing robust and efficient power transfer. -

Industrial Machinery & Automation:

Used in manufacturing plants and heavy machinery, where high current loads and continuous operation demand superior electrical performance. -

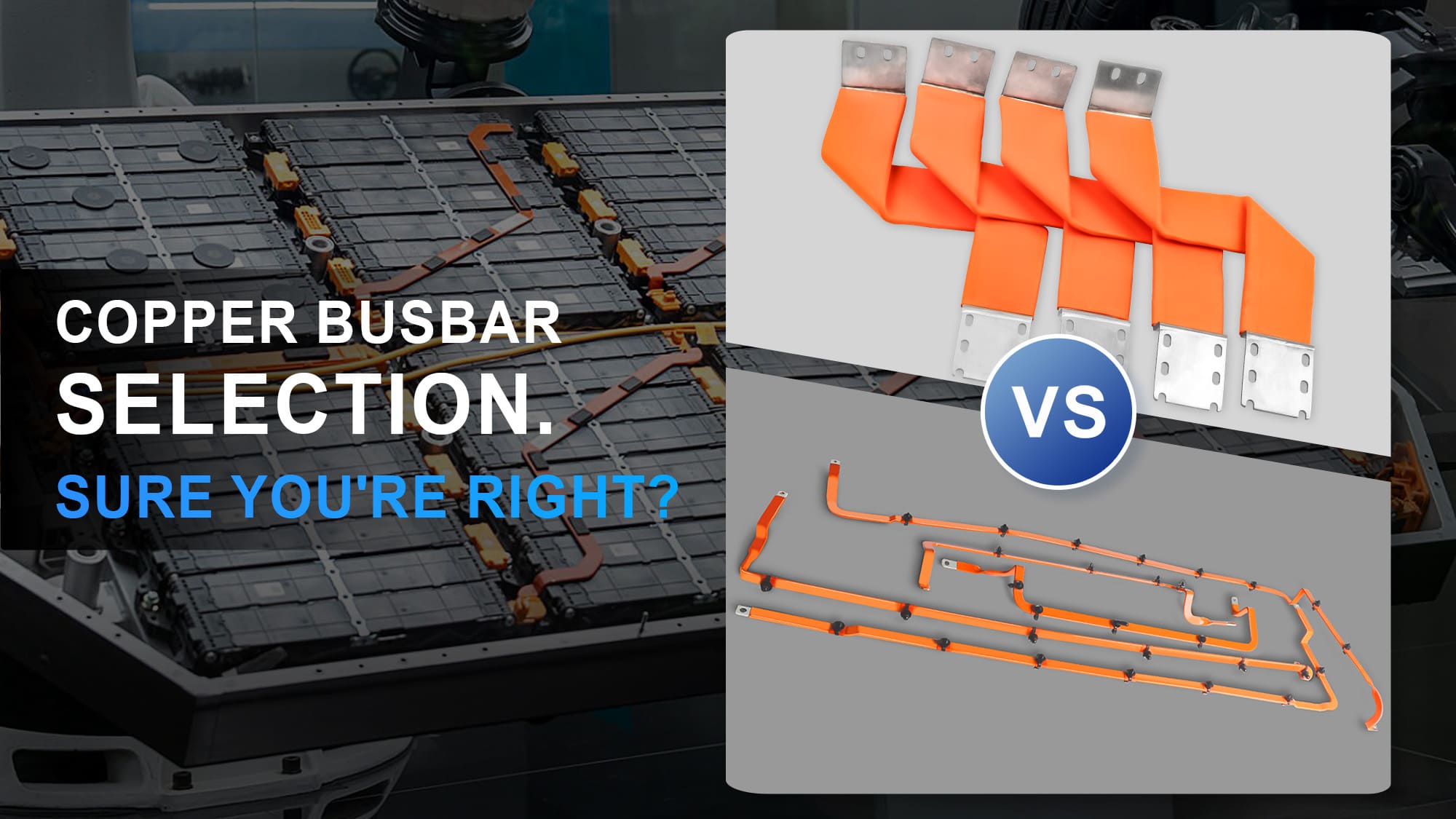

Electric Vehicles (EV) & Transportation:

Contributes to the safe and efficient operation of charging stations and high-power electric drive systems, ensuring optimal energy distribution.

RHI Manufacturer Service Advantages

Expertise and Quality Assurance

-

Decades of Industry Experience:

RHI has built a reputation for excellence in copper busbar manufacturing, drawing on years of expertise to produce reliable, high-quality products. -

Rigorous Quality Control:

Every busbar undergoes extensive testing and quality assurance processes to ensure consistent performance and adherence to international standards.

Customization & Technical Support

-

Tailored Solutions:

We work closely with clients to design and manufacture busbars that meet unique project specifications, offering customization in terms of dimensions, plating, and performance. -

Dedicated Engineering Team:

Our in-house experts provide comprehensive technical support—from initial design consultations to post-installation services—ensuring your project’s success.

On-Time Delivery & Global Reach

-

Efficient Production & Logistics:

With a streamlined manufacturing process and robust supply chain management, RHI guarantees timely delivery, no matter where your project is located. -

Global Customer Support:

Our commitment to customer satisfaction extends worldwide, offering multilingual support and rapid response times to meet the needs of diverse markets.

Why Choose RHI's Rigid Copper Busbars?

RHI's rigid copper busbars stand at the forefront of power distribution technology, combining unmatched electrical performance with durability and customizability. Whether you’re designing critical infrastructure or upgrading existing systems, our busbars provide a reliable, efficient solution engineered to exceed your expectations.

Elevate your power systems with RHI – where quality, innovation, and customer satisfaction converge.