EV Battery Thermal Management: Four Cooling Technologies Explained

How Do EV Batteries "Cool Down" ? Four Key Thermal Management Technologies

With the rapid evolution of new energy vehicles, the traction battery is not only the “heart” of an electric vehicle but also a decisive factor for performance, safety, and service life.

Lithium-ion batteries, widely adopted for their high energy density and long cycle life, operate much like a precision biological system—stable temperature control is essential for safe and efficient operation.

1. Why Do Batteries Require Thermal Control?

The Dual Challenge of Overheating and Overcooling

Heat generation is inevitable during battery charge and discharge. For high-capacity, high-energy-density EV battery packs, heat accumulation and temperature non-uniformity become critical engineering challenges.

High-temperature risks

- Battery electrochemical systems are inherently sensitive to heat

- For every 10 °C increase, battery aging typically accelerates by ~2×

- Studies show that Sony 18650 cells cycled at 50 °C can lose up to 60% capacity after 500 cycles

- Excessive heat accelerates active material degradation, increases internal resistance, and may trigger thermal runaway

Low-temperature limitations

- Reduced ionic activity limits charge/discharge power

- Capacity and driving range decline sharply

- User experience and fast-charging capability are compromised

Thermal management objective

Maintain battery operation within an optimal 25–40 °C window, ensuring efficient heat dissipation at high temperatures and effective heating in cold environments.

This article focuses specifically on battery cooling technologies.

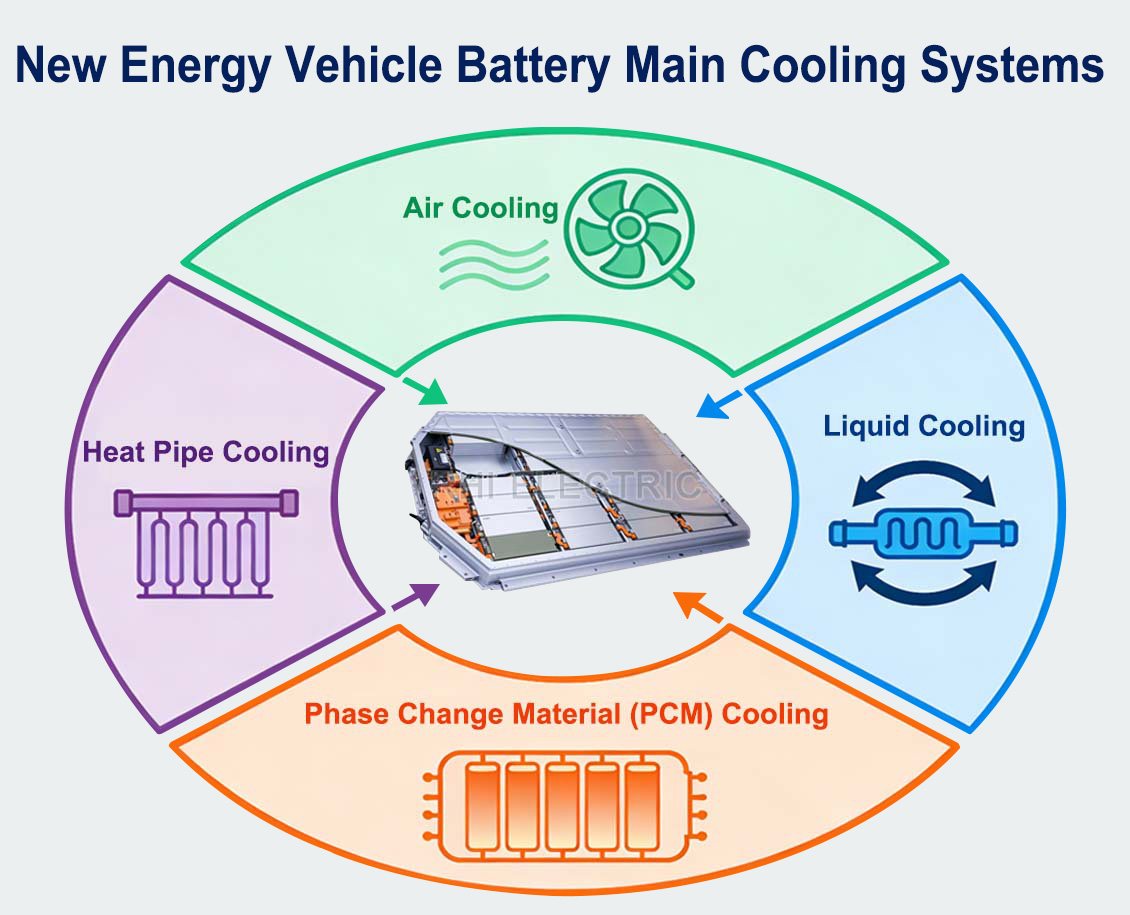

2. Mainstream Battery Cooling Technologies

Four Proven Thermal Management Pathways

Modern EV battery systems typically rely on four mature cooling approaches, which together form the foundation of battery safety and performance.

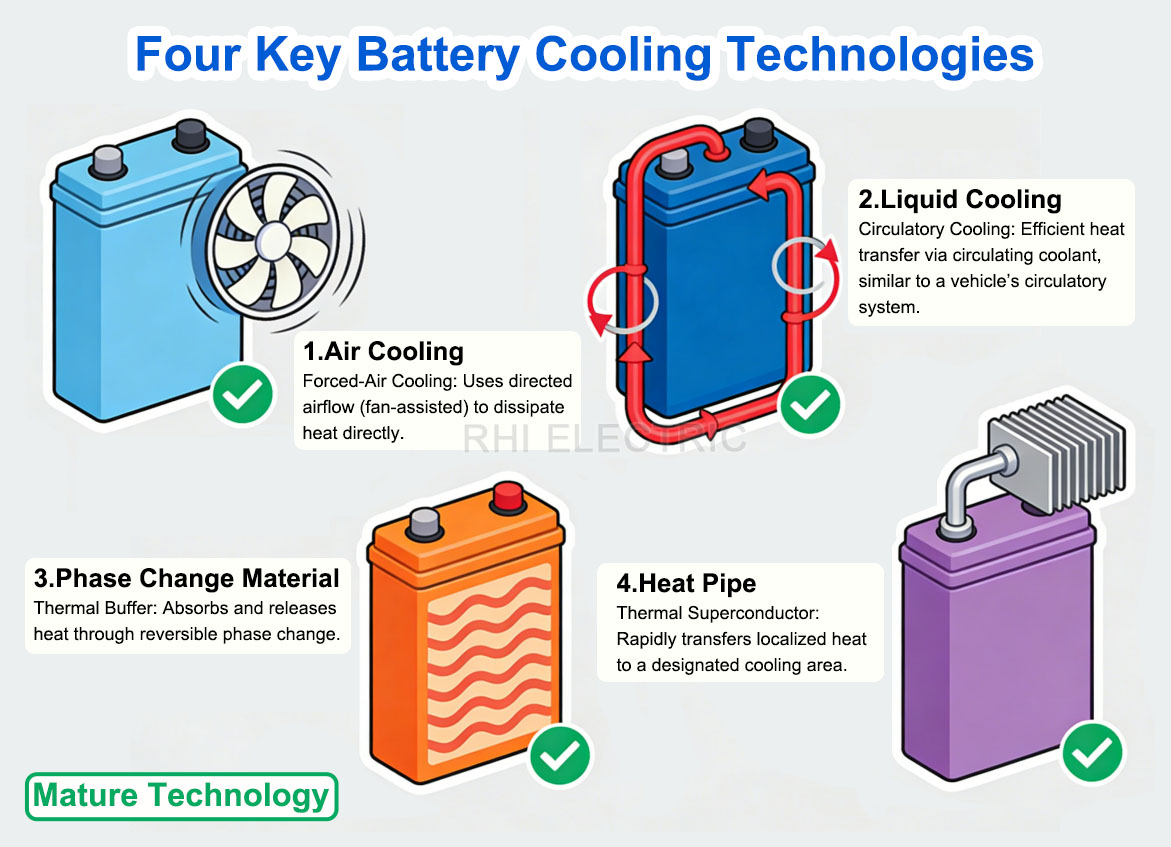

2.1 Air Cooling System (AC) – Forced or Natural Convection

Operating principle

Heat is dissipated through airflow, either via:

- Natural convection generated by vehicle motion

- Forced convection using fans

Engineering perspective

Air cooling offers simple architecture and low cost, making it suitable for early EV platforms. However, due to air’s low thermal conductivity and heat capacity, its cooling capability is fundamentally limited.

- As battery energy density and fast-charging demands increase, air cooling struggles to:

- Control temperature rise during sustained high-power operation

- Maintain uniform temperature distribution across the pack

Typical applications

Low-power EVs, micro vehicles, and cost-sensitive platforms with modest thermal loads.

2.2 Liquid Cooling System (LC) – The Industry Standard

Operating principle

A pump circulates coolant (typically a water-glycol mixture) through micro-channel cold plates integrated into battery modules. Heat is transferred to a front-end radiator for dissipation.

Engineering perspective

With thermal conductivity and heat capacity orders of magnitude higher than air, liquid cooling enables:

- Precise temperature control

- Excellent thermal uniformity

- Support for fast charging and high-power output

Liquid cooling has become the default solution for mid- to high-end EVs.

Engineering challenges

- Increased system complexity (pumps, valves, piping)

- Added weight

- Strict requirements for sealing reliability, corrosion resistance, and long-term durability

2.3 Heat Pipe Cooling (HP) – Local Hotspot Management

Operating principle

Heat pipes use a sealed working fluid (e.g., water or acetone) that undergoes rapid evaporation–condensation cycles to transfer heat efficiently with minimal temperature difference.

Engineering perspective

Heat pipes exhibit extremely high axial thermal conductivity, often equivalent to thousands of times that of solid copper.

In EV battery systems, heat pipes are rarely used as standalone cooling solutions. Instead, they act as:

- Thermal superhighways

- Temperature-equalization enhancers

They are commonly integrated into liquid cooling plates or module interfaces to:

- Extract heat from localized hotspots

- Improve overall temperature consistency

- Mitigate the “weakest-cell” effect

2.4 Phase Change Material Cooling (PCM)

Operating principle

PCM absorbs or releases large amounts of latent heat during solid–liquid phase transitions, stabilizing temperature around its phase-change point.

Engineering perspective

Key advantages:

- Fully passive operation

- Zero energy consumption

- Excellent thermal buffering characteristics

Limitations:

- Intrinsically low thermal conductivity

- Slow heat transfer without enhancement

Practical application

PCM is rarely used alone. Instead, it functions as a thermal buffer combined with active systems (typically liquid cooling), where it:

- Absorbs transient heat spikes

- Slows temperature rise

- Reduces peak load on the primary cooling loop

3. System Integration and Future Trends

Multi-Technology Synergy Is the Future

As EV batteries push toward higher energy density and faster charging, single cooling solutions reach their limits. The industry trend is clear: hybrid thermal management architectures.

Typical configurations include:

- Liquid cooling + PCM: thermal buffering and peak-load reduction

- Liquid/air cooling + heat pipes: rapid hotspot extraction and temperature equalization

- Direct refrigerant cooling: using HVAC refrigerant for extremely high cooling efficiency (applied in select premium EVs)

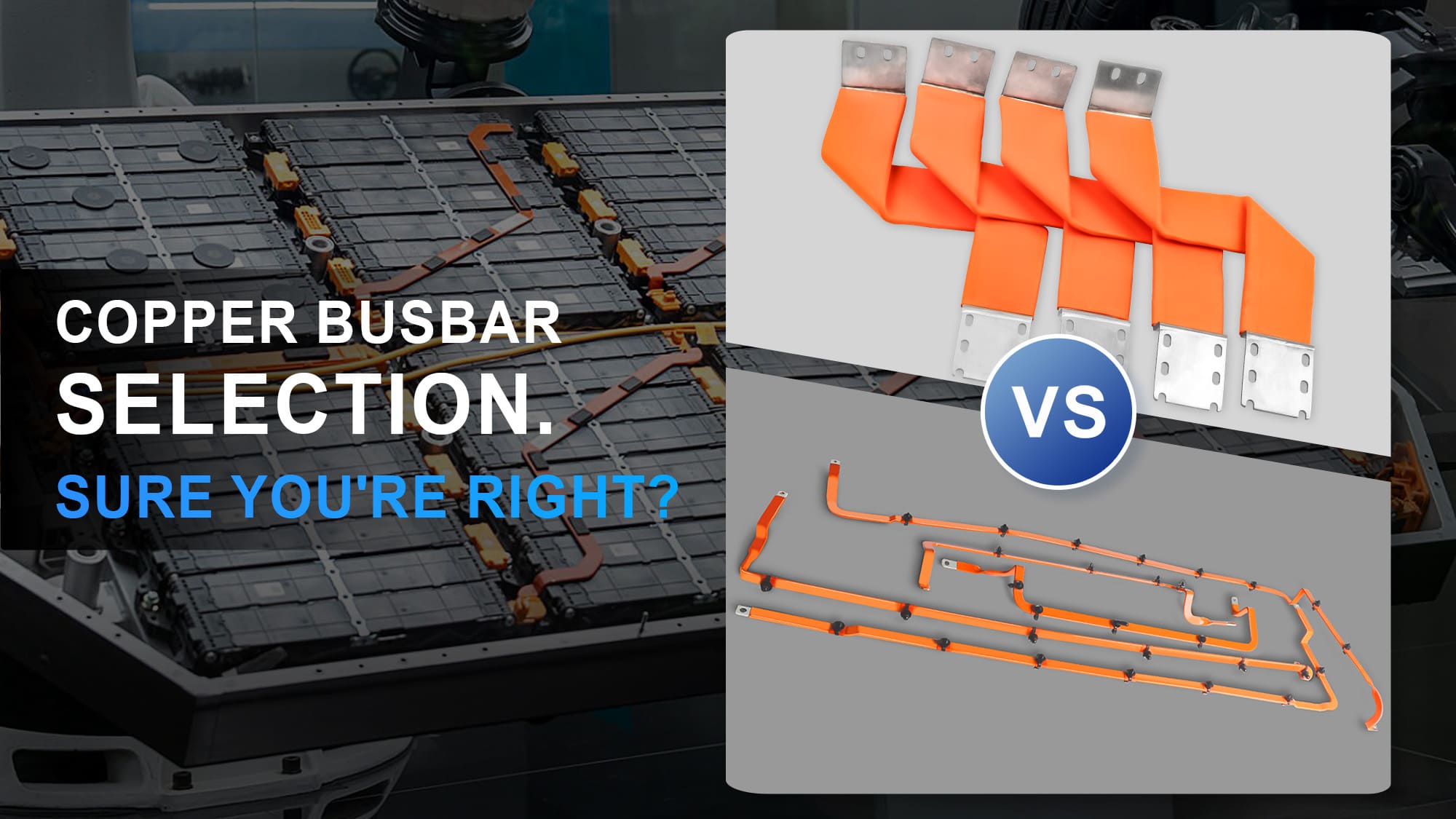

4. Material-Driven Thermal Design

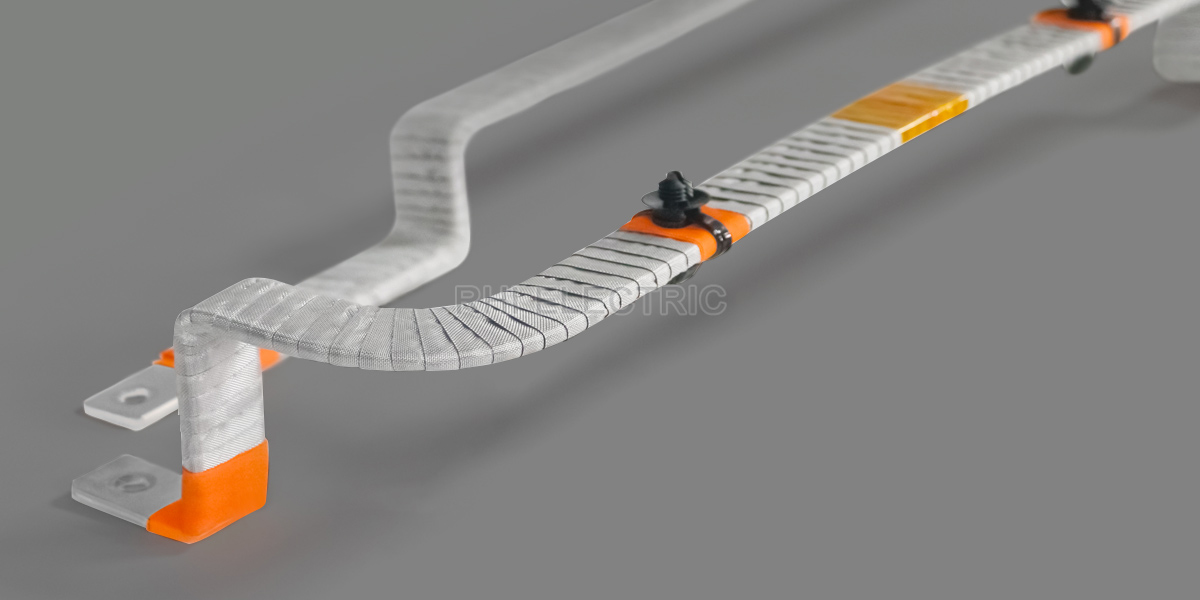

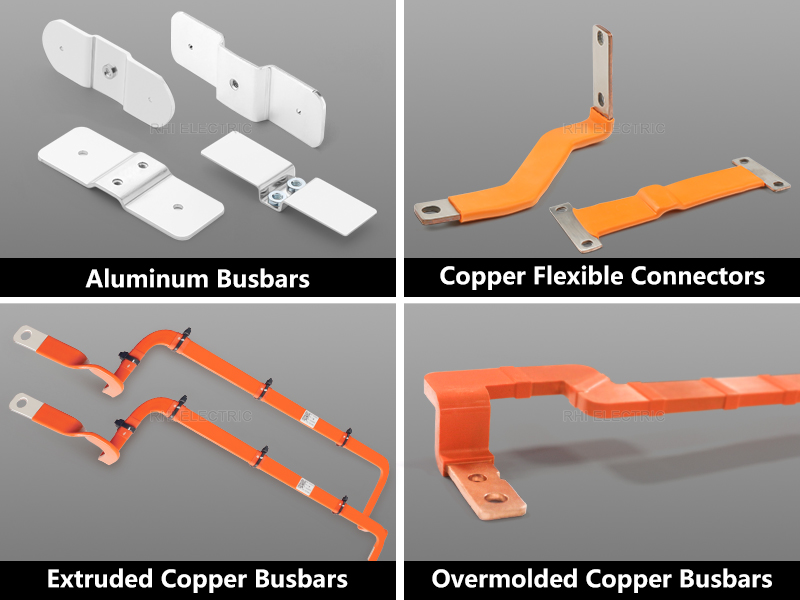

How RHI Busbars Empower Advanced Battery Thermal Management

Every mainstream battery cooling technology—liquid cooling, air cooling, heat pipes, PCM, and even emerging thermoelectric cooling—places unique thermal and structural demands on busbars, the critical electrical conductors inside battery packs.

As a leading supplier of copper and aluminum busbar and interconnection solutions, RHI leverages deep material expertise and advanced manufacturing processes to deliver cooling-adaptive, safety-driven busbar systems, acting as both:

- Efficient thermal conductors

- Reliable electrical bridges

4.1 Busbar Solutions for Thermoelectric Cooling (TEC)

Precision thermal coupling

Thermoelectric modules require extremely low thermal contact resistance.

RHI supplies high-flatness nickel-plated copper busbars, ensuring:

- Stable thermal interfaces

- Oxidation resistance

- Reliable contact with TEC modules or thermally conductive insulation pads

High-temperature electrical insulation

TEC systems introduce localized hot-cold gradients.

RHI’s high-temperature busbars featuring:

- Inner mica tape

- Outer ceramic composite tape

maintain dielectric strength and mechanical stability under repeated thermal cycling.

System integration readiness

Custom aluminum busbars can be machined with:

- Sensor mounting holes

- Flat reference surfaces

- Structural features for BMS integration

supporting closed-loop thermal and electrical control.

4.2 Busbars for Heat Pipe Cooling Systems

High-efficiency thermal bases

With thermal conductivity around 385 W/m·K, RHI copper busbars act as effective heat spreaders, transferring localized heat efficiently to heat pipe evaporator sections.

Flexible spatial integration

RHI offers:

- Copper/aluminum laminated flexible connectors

- Multi-angle 3D-bent rigid busbars

allowing electrical routing around heat pipes while preserving optimal airflow or cold-plate contact.

Material matching across temperature ranges

- Copper busbars for high-temperature, high-power zones

- Aluminum busbars for lightweight, moderate-temperature areas

All with extrusion or injection-molded insulation for long-term reliability.

4.3 Core Busbar Value in Mainstream Cooling Systems

Liquid cooling systems

RHI busbars provide:

- Flat, tin- or nickel-plated surfaces for low thermal resistance

- High-sealing insulation via insert molding or PA12 extrusion

effectively mitigating coolant leakage and condensation risks.

Air cooling systems

Thermal performance is enhanced through:

- Optimized busbar geometry for airflow

- Perforated or frame-type structures to increase heat dissipation area

- Bare copper or bright tin finishes to improve radiative heat transfer

PCM-assisted cooling

RHI addresses long-term interface reliability by offering:

- Surface-treated busbars for improved PCM adhesion

- Fully encapsulated insulation (e.g., PA66+GF30 injection molding)

preventing chemical interaction and ensuring stable electrical performance over time.

5. Conclusion

Battery thermal management is a precise balance between safety, performance, and durability. From air cooling to liquid cooling, and from heat pipes to phase-change materials, the continuous evolution and integration of cooling technologies are driving EV batteries toward higher energy density and faster charging.

As thermal management systems become more integrated and intelligent, electrical interconnection design plays an increasingly critical role.

As a trusted partner in battery interconnection solutions, RHI supports this evolution by delivering:

helping customers build efficient, reliable, and future-ready battery thermal management systems.