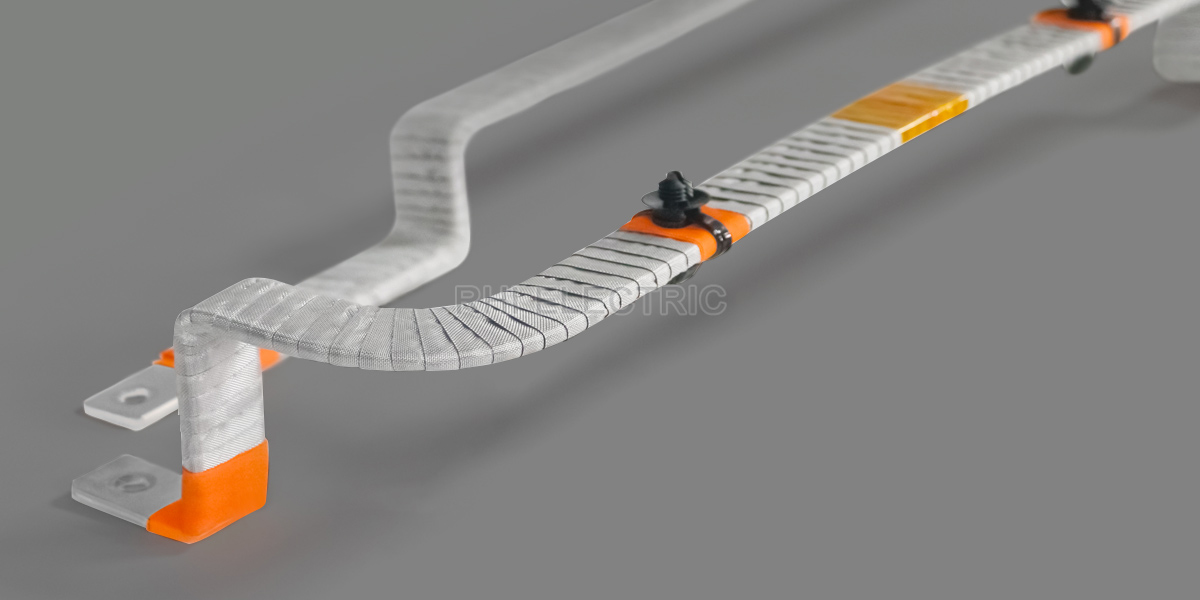

Battery Busbar Insulated with Ceramic Composite Tape

Ceramic Composite Tape Busbars: These battery busbars combine heat-resistant ceramic tape with conductors to meet EV system demands for insulation, heat resistance, and strength. RHI's automated winding ensures uniform, secure wrapping, enhancing thermal and electrical performance. Ideal for high-voltage battery pack connections.

EV Battery Busbars with Heat-Resistant Ceramic Tape

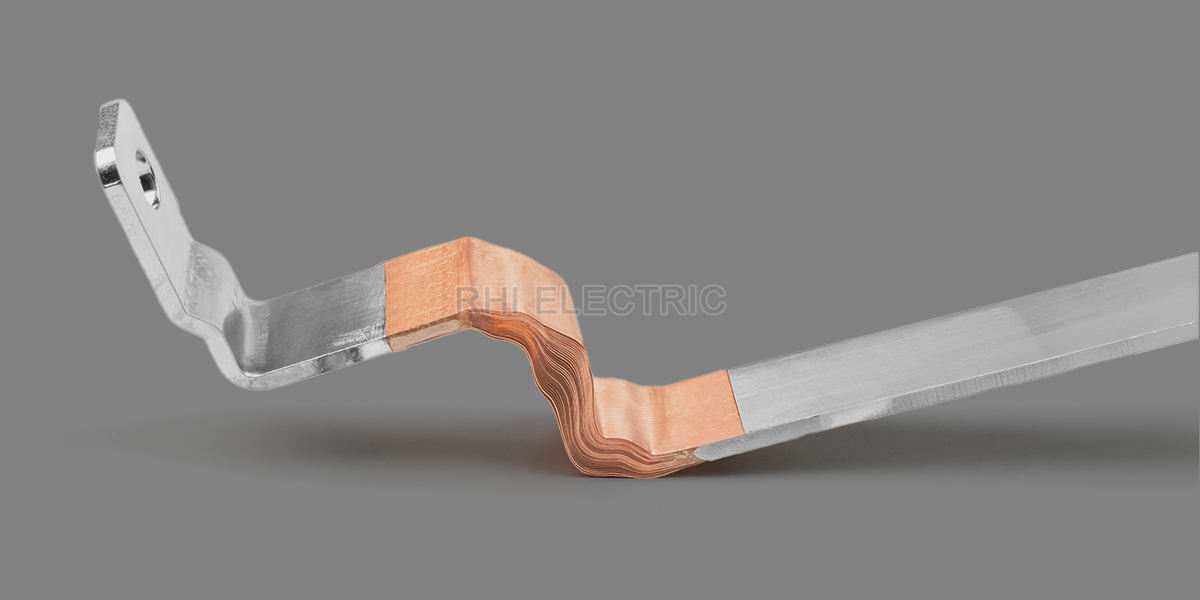

RHI’s ceramic composite tape busbars integrate high-temperature ceramic fiber insulation with conductive busbars, designed to meet the stringent requirements of electric vehicle power systems for thermal resistance, insulation, and mechanical strength.

With advanced automated winding technology, we ensure precise, uniform tape application and strong adhesion, significantly enhancing the busbar’s thermal and electrical insulation performance. This solution is ideal for high-voltage battery pack connections in new energy vehicles.

Click here to view the automated winding process.

Process Features

Premium Material Selection: The ceramic composite tape is made from high-temperature ceramic fibers, offering reliable thermal protection and electrical insulation for high-voltage connections under extreme conditions.

Precision Wrapping Process: Automated winding equipment applies the tape with controlled tension and angle, ensuring uniform coverage and tight adhesion. This enhances insulation integrity and thermal resistance while preventing delamination.

Product Advantages

- Excellent Heat Resistance: Ensures stable operation in high-temperature environments and effectively mitigates thermal runaway risks.

- Outstanding Insulation Performance: Enhances electrical isolation, reduces leakage risks, and improves overall system safety.

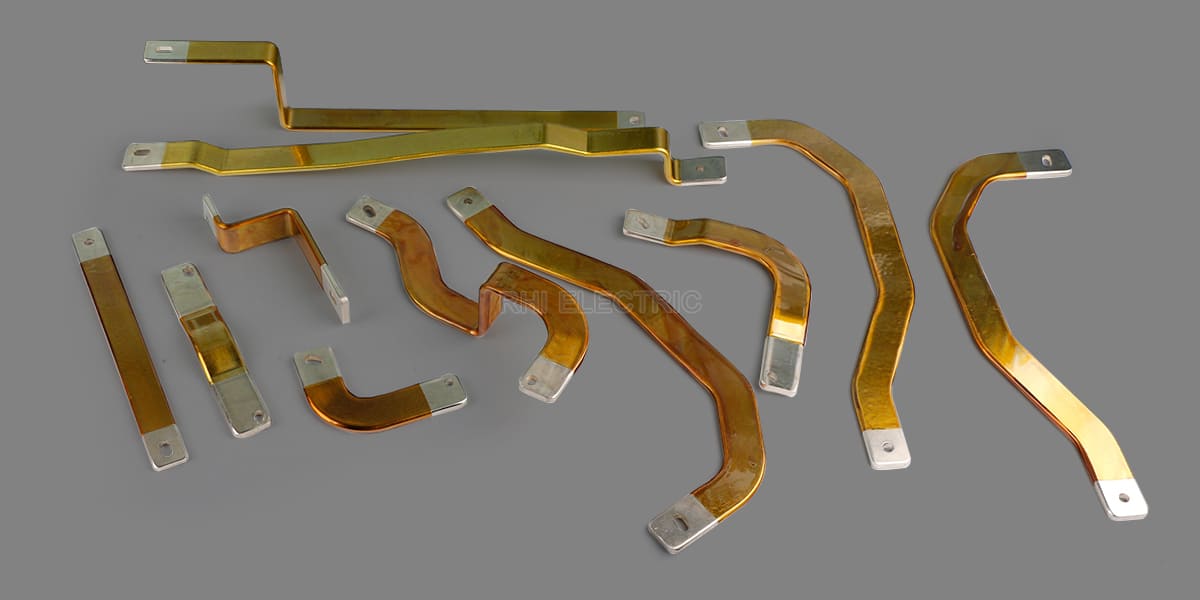

- High Mechanical Strength: Provides strong tensile, bending, and impact resistance, ideal for complex installation scenarios.

- Superior Corrosion Resistance: Withstands chemical exposure, extending service life.

- Easy and Flexible Installation: Compatible with various electrical system layouts for efficient integration and wiring.

Technical Specifications

- Withstands 1000°C flame exposure for 10 minutes

- Dielectric strength: 3500V DC / 60s, leakage current <1mA

- Insulation performance: 1000V DC / 60s, insulation resistance >500MΩ

- Available in both rigid and flexible busbar formats for diverse applications

Application

Thanks to its exceptional thermal and insulation properties, this solution is widely used in high-voltage connections within EV battery packs, especially in demanding environments requiring advanced heat resistance and electrical safety.