Zhejiang RHI Electric Co., Ltd.

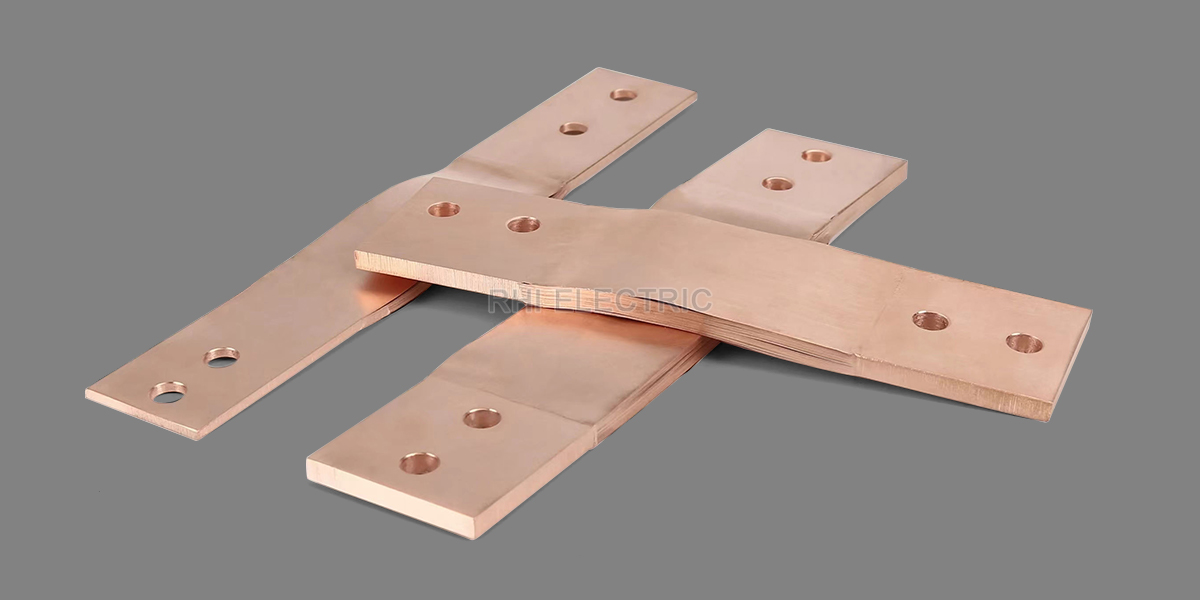

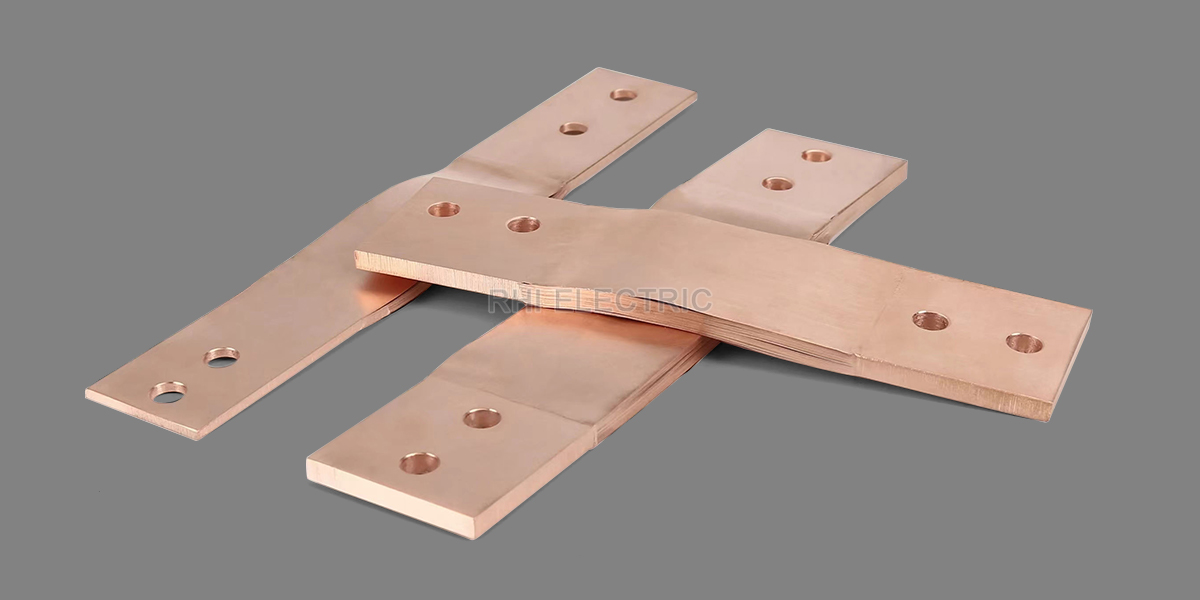

Detailed Characteristics of Flexible Copper Busbar

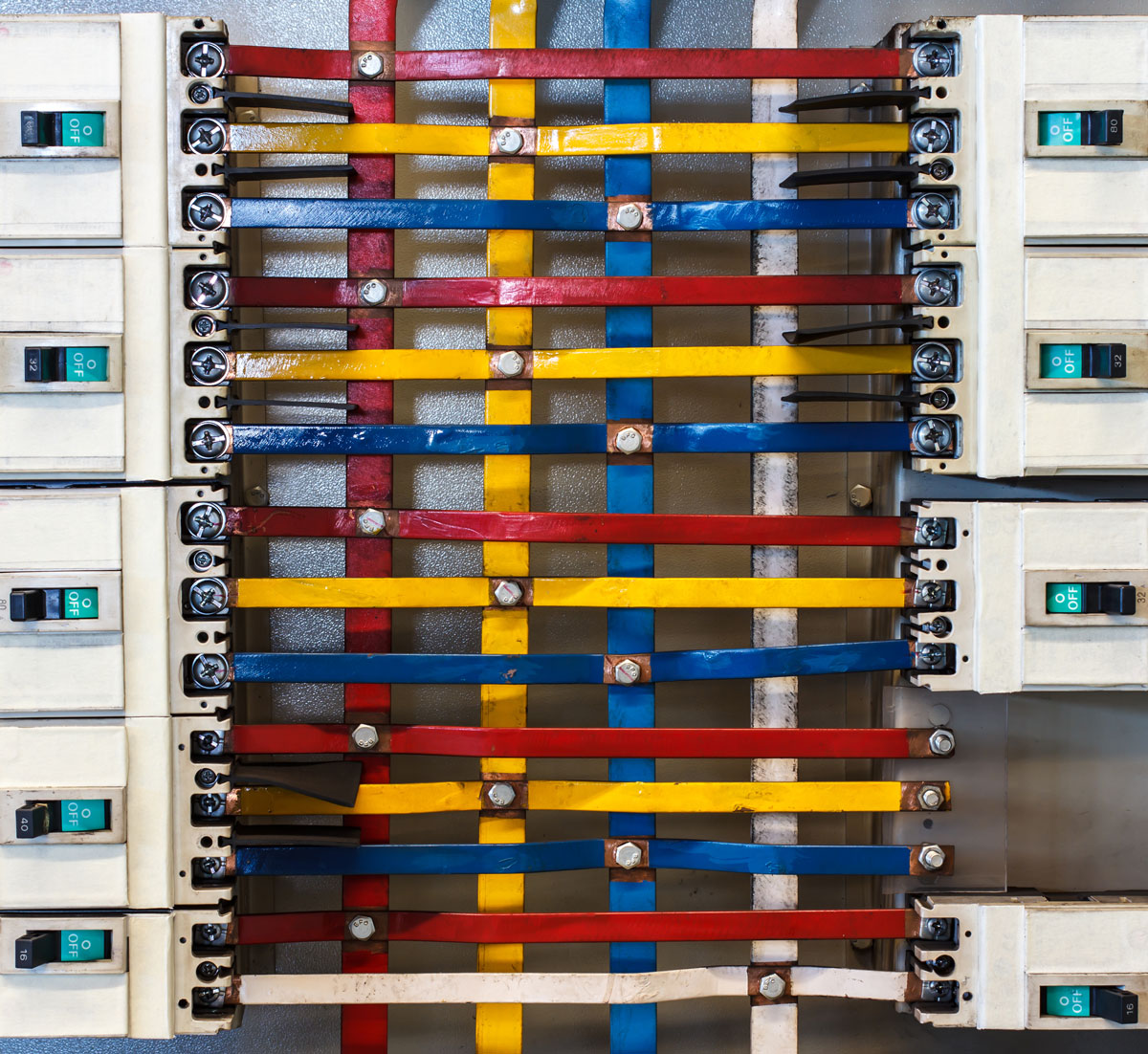

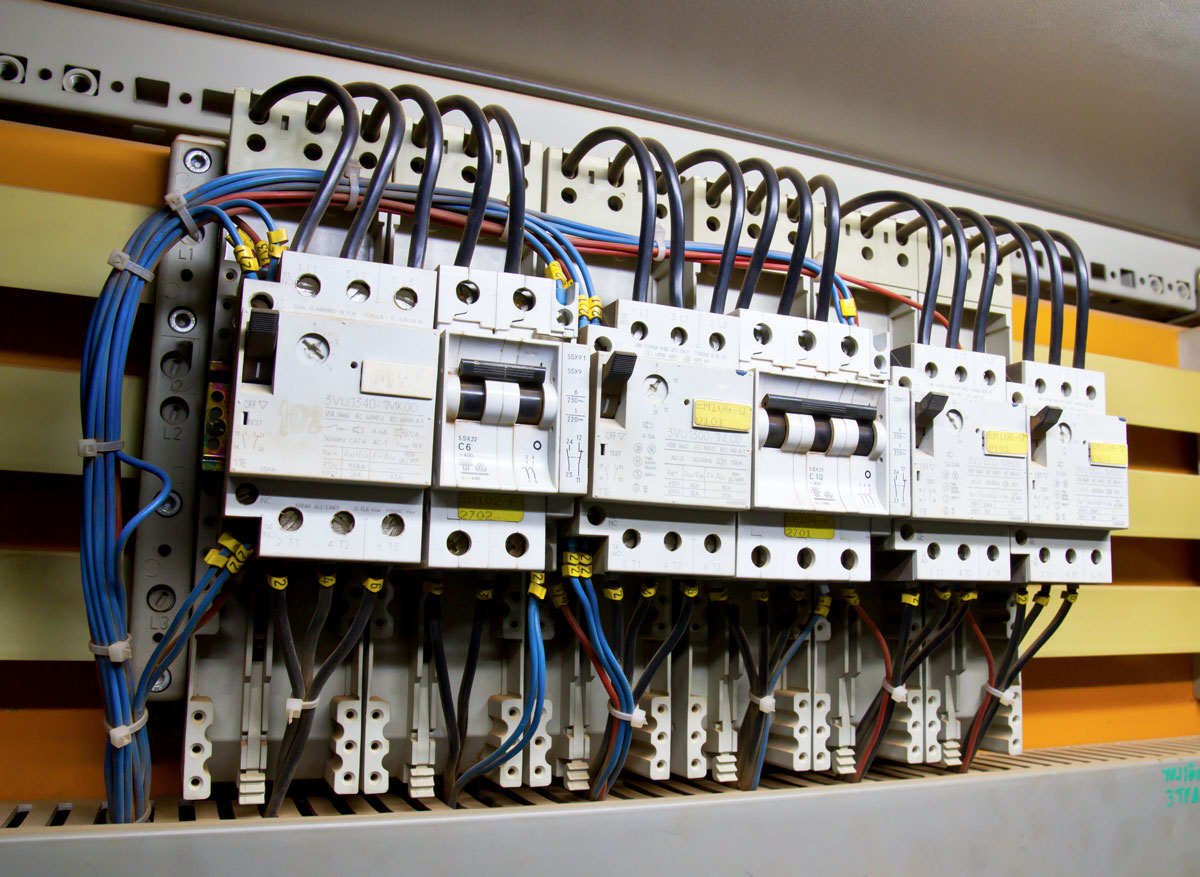

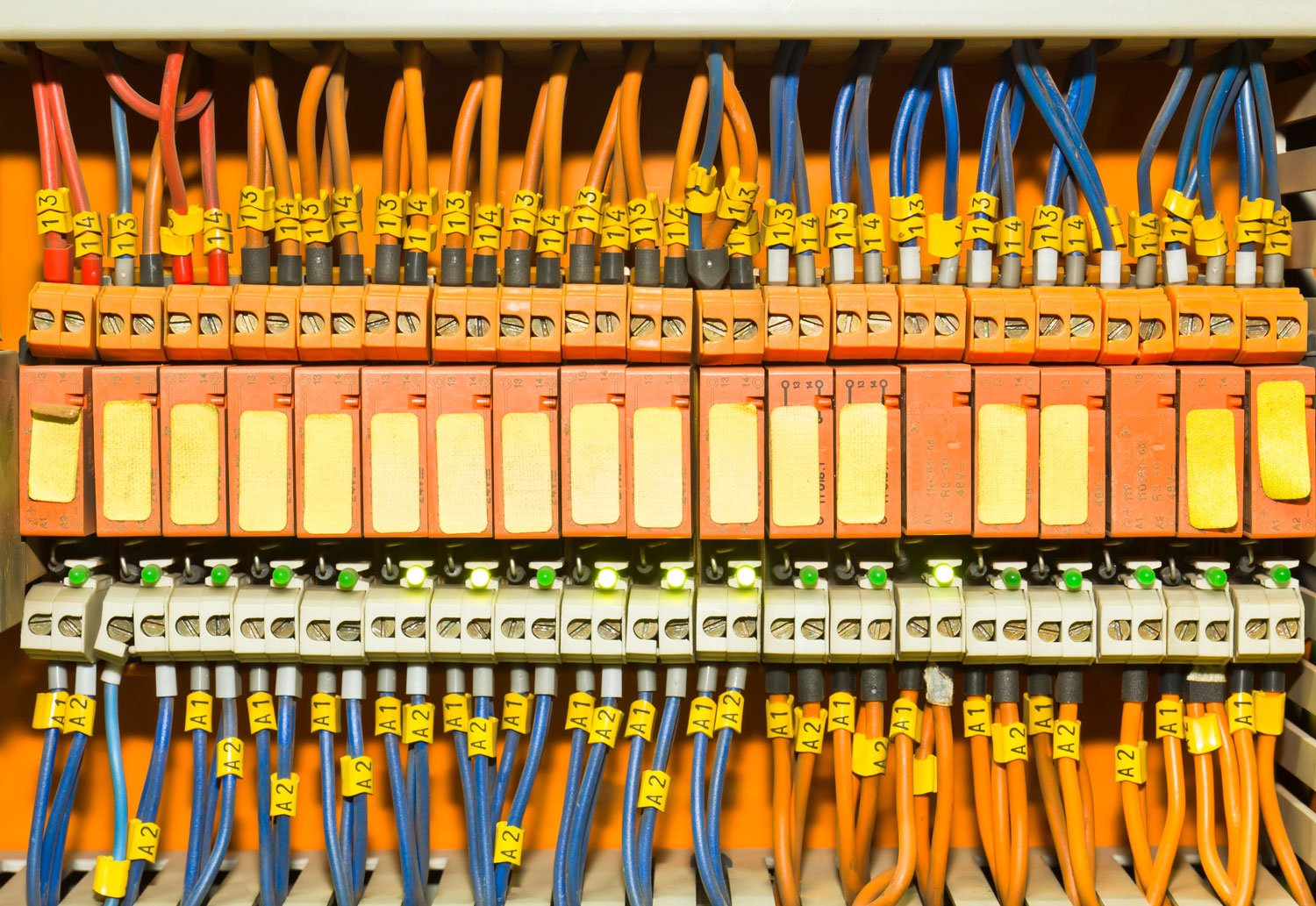

Flexible copper busbars are highly versatile electrical components used in power distribution systems, industrial applications, and various electrical devices. They combine the excellent electrical and thermal properties of copper with enhanced flexibility, making them ideal for installations where conventional rigid busbars are impractical

more

Flexible copper busbars are highly versatile electrical components used in power distribution systems, industrial applications, and various electrical devices. They combine the excellent electrical and thermal properties of copper with enhanced flexibility, making them ideal for installations where conventional rigid busbars are impractical

Superior Electrical Conductivity

- Unmatched Conductivity: Flexible copper busbars inherit copper’s 100% IACS conductivity, which makes them highly efficient for transmitting electrical power with minimal energy loss.

- Low Resistance: The high conductivity ensures that flexible copper busbars can handle high current loads efficiently, improving the overall energy efficiency of electrical systems.

- Stable Performance: Copper's electrical properties are stable over time, making flexible copper busbars suitable for long-term, reliable operation in demanding environments.

more

Unmatched Conductivity: Flexible copper busbars inherit copper’s 100% IACS conductivity, which makes them highly efficient for transmitting electrical power with minimal energy loss.

Low Resistance: The high conductivity ensures that flexible copper busbars can handle high current loads efficiently, improving the overall energy efficiency of electrical systems.

Stable Performance: Copper's electrical properties are stable over time, making flexible copper busbars suitable for long-term, reliable operation in demanding environments.

Enhanced Flexibility

- Bendable and Shapeable: Flexible copper busbars are designed to be easily bent, twisted, and shaped according to the installation requirements, making them ideal for compact or challenging spaces.

- Adaptable to Complex Configurations: They can be used in tight spaces or custom layouts where rigid copper busbars would be difficult to install, providing more design flexibility in complex electrical systems.

- Ease of Installation: The flexibility allows for easier routing and installation in confined spaces without the need for additional tools or equipment, saving time and reducing labor costs.

more

Bendable and Shapeable: Flexible copper busbars are designed to be easily bent, twisted, and shaped according to the installation requirements, making them ideal for compact or challenging spaces.

Adaptable to Complex Configurations: They can be used in tight spaces or custom layouts where rigid copper busbars would be difficult to install, providing more design flexibility in complex electrical systems.

Ease of Installation: The flexibility allows for easier routing and installation in confined spaces without the need for additional tools or equipment, saving time and reducing labor costs.

.jpg)

High Durability and Long Life

- Robust Mechanical Properties: Flexible copper busbars combine copper’s excellent mechanical strength with a flexible, multi-strand design, which provides enhanced durability under mechanical stress.

- Resistant to Fatigue: The multi-strand construction reduces the risk of material fatigue due to repeated bending or vibration, ensuring long-term reliability even in dynamic environments.

- Resistance to Corrosion: Flexible copper busbars maintain copper's natural corrosion resistance, which protects them in various operating environments. While flexible versions may require additional coatings in extremely harsh environments, their inherent durability remains a key benefit.

more

Robust Mechanical Properties: Flexible copper busbars combine copper’s excellent mechanical strength with a flexible, multi-strand design, which provides enhanced durability under mechanical stress.

Resistant to Fatigue: The multi-strand construction reduces the risk of material fatigue due to repeated bending or vibration, ensuring long-term reliability even in dynamic environments.

Resistance to Corrosion: Flexible copper busbars maintain copper's natural corrosion resistance, which protects them in various operating environments. While flexible versions may require additional coatings in extremely harsh environments, their inherent durability remains a key benefit.

Excellent Thermal Conductivity

- Effective Heat Dissipation: Copper’s high thermal conductivity allows flexible copper busbars to dissipate heat efficiently, reducing the risk of overheating and maintaining safe operating temperatures.

- Heat Management: This property ensures that flexible copper busbars remain stable even during high current flows, contributing to the longevity of electrical components and improving system efficiency.

more

Effective Heat Dissipation: Copper’s high thermal conductivity allows flexible copper busbars to dissipate heat efficiently, reducing the risk of overheating and maintaining safe operating temperatures.

Heat Management: This property ensures that flexible copper busbars remain stable even during high current flows, contributing to the longevity of electrical components and improving system efficiency.

Ease of Customization

- Tailored Solutions: Flexible copper busbars can be easily customized in terms of length, shape, and layout to meet specific design requirements. This makes them ideal for both standard and unique electrical systems, including complex installations or specialized equipment.

- Variety of Configurations: They can be produced in various forms, such as single or multi-conductors, flat or round profiles, or even insulated versions, depending on the application.

more

Tailored Solutions: Flexible copper busbars can be easily customized in terms of length, shape, and layout to meet specific design requirements. This makes them ideal for both standard and unique electrical systems, including complex installations or specialized equipment.

Variety of Configurations: They can be produced in various forms, such as single or multi-conductors, flat or round profiles, or even insulated versions, depending on the application.

High Solderability and Connectivity

- Superior Soldering Properties: Flexible copper busbars are highly solderable, allowing for reliable electrical connections and ensuring low contact resistance.

- Strong and Stable Connections: These soldered joints contribute to the stability and reliability of the entire electrical system, providing secure and efficient current flow.

more

Superior Soldering Properties: Flexible copper busbars are highly solderable, allowing for reliable electrical connections and ensuring low contact resistance.

Strong and Stable Connections: These soldered joints contribute to the stability and reliability of the entire electrical system, providing secure and efficient current flow.

Vibration and Shock Resistance

- Impact Absorption: The flexibility of copper busbars allows them to absorb mechanical vibrations or shocks, making them ideal for systems subject to movement, such as electric vehicles, rail transit, or equipment in high-vibration environments.

- Reduced Risk of Damage: Unlike rigid busbars, which are more prone to cracks or breakage from physical impact, flexible copper busbars remain resilient and reliable.

more

Impact Absorption: The flexibility of copper busbars allows them to absorb mechanical vibrations or shocks, making them ideal for systems subject to movement, such as electric vehicles, rail transit, or equipment in high-vibration environments.

Reduced Risk of Damage: Unlike rigid busbars, which are more prone to cracks or breakage from physical impact, flexible copper busbars remain resilient and reliable.

Lightweight Construction

- Reduced Weight: Flexible copper busbars, though made of copper, are lighter than their rigid counterparts due to their design and structure. This contributes to easier handling, installation, and transport.

- Energy Savings: Lighter busbars reduce the overall weight of electrical systems, which can be crucial in applications such as electric vehicles (EVs), aerospace, or portable equipment where weight is a critical factor.

more

Reduced Weight: Flexible copper busbars, though made of copper, are lighter than their rigid counterparts due to their design and structure. This contributes to easier handling, installation, and transport.

Energy Savings: Lighter busbars reduce the overall weight of electrical systems, which can be crucial in applications such as electric vehicles (EVs), aerospace, or portable equipment where weight is a critical factor.

From Our Blog

Jan 27, 2026

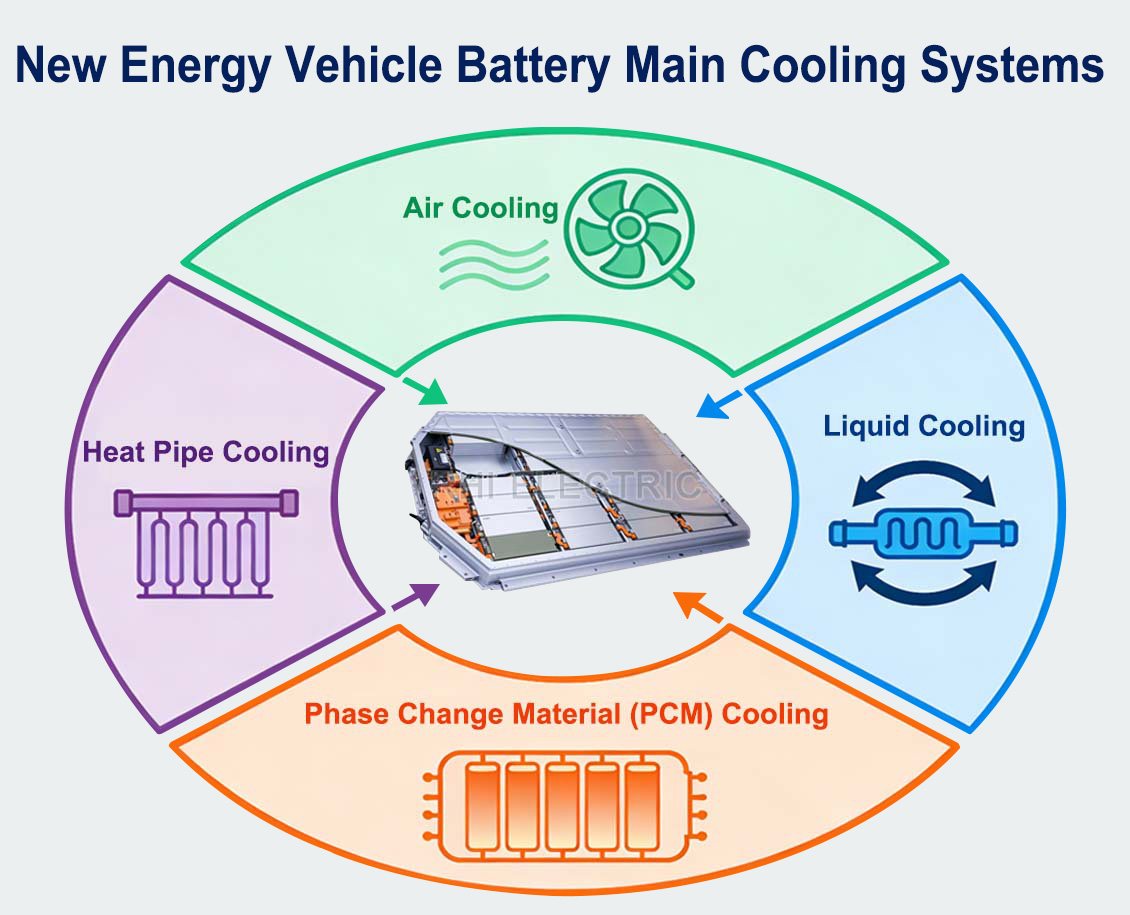

Thermal control defines interconnection performance in high-efficiency energy systems. Rigid copper busbars enable directional heat conduction, while flexible laminated connectors provide heat dissipation and mechanical compliance. Backed by simulation-driven design and advanced manufacturing, RHI delivers low-temperature-rise, high-reliability interconnection solutions for next-generation new energy systems.

Jan 24, 2026

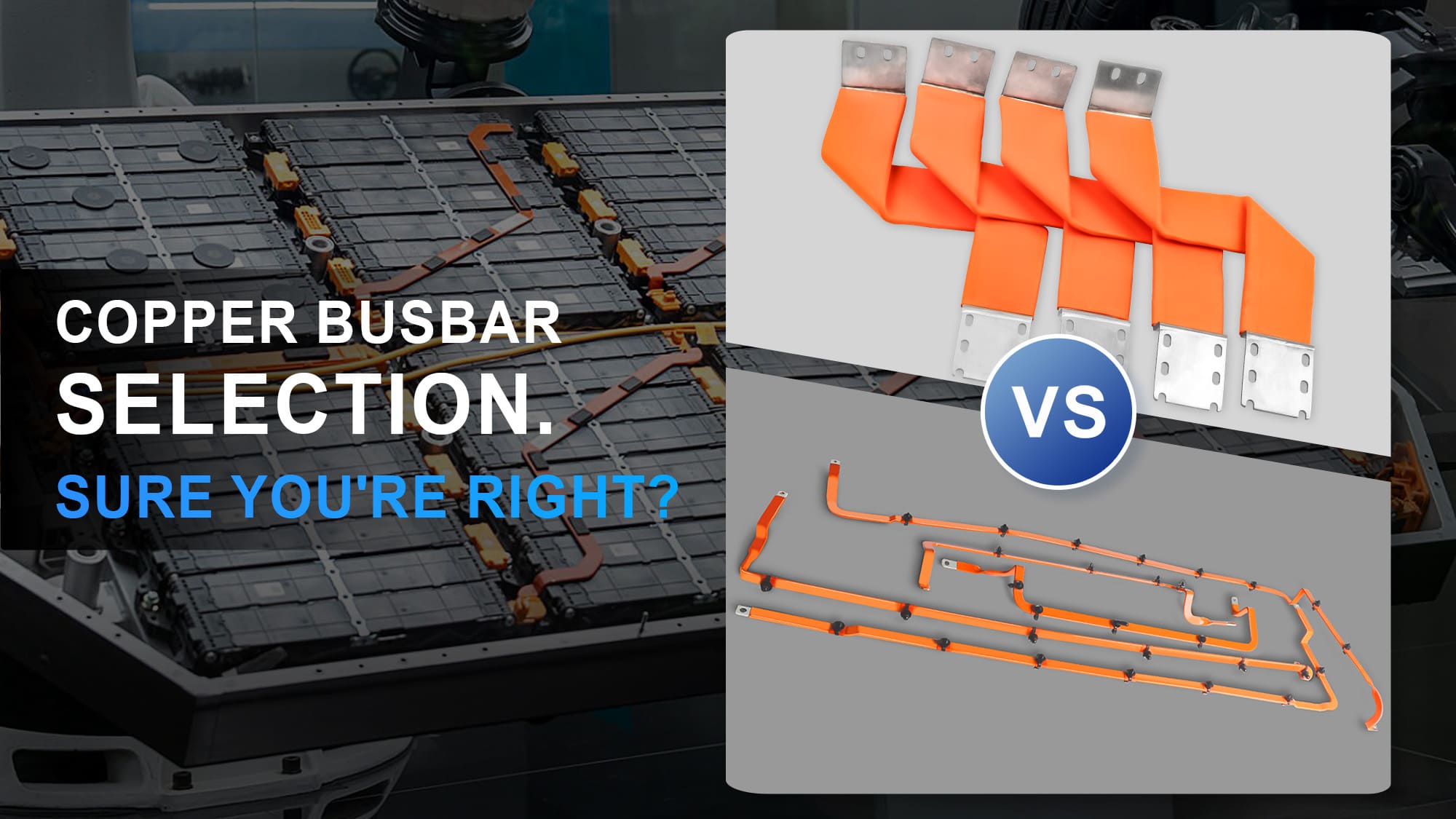

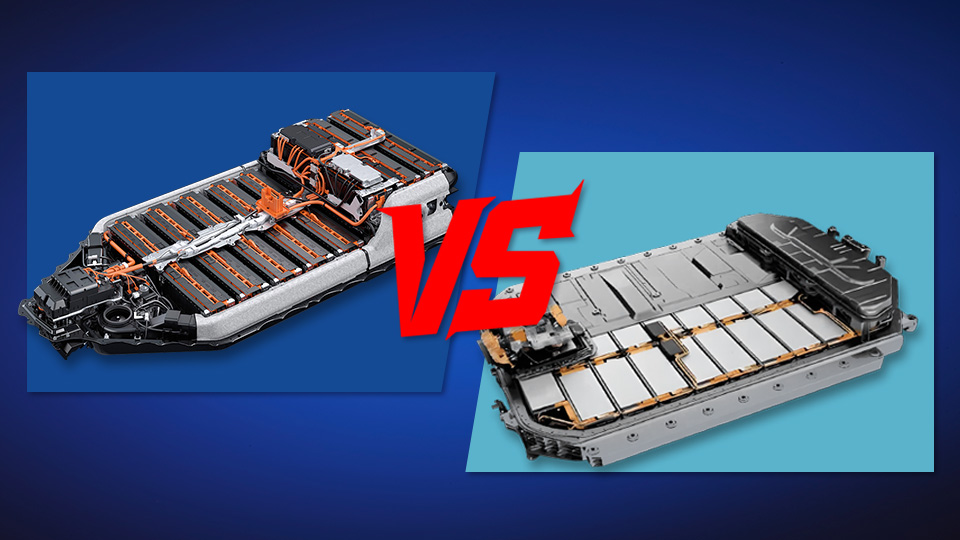

The performance of a battery pack is determined not only by cell chemistry (NCM/NCA vs. LFP), but equally by the design of its busbar and interconnection system. Selecting the correct busbar solution is critical to fully realizing the inherent advantages of the chosen cells.