Unlock Battery Potential — The Right Busbar Makes the Difference

The performance of a battery pack is determined not only by cell chemistry (NCM/NCA vs. LFP), but equally by the design of its busbar and interconnection system. Selecting the correct busbar solution is critical to fully realizing the inherent advantages of the chosen cells.

Cells Define Performance Limits; Busbars Set the Safety Ceiling

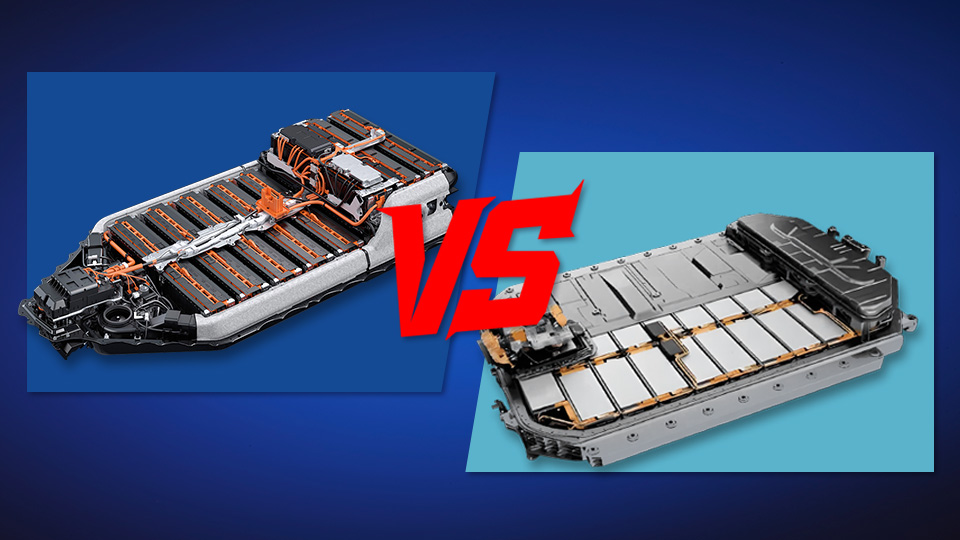

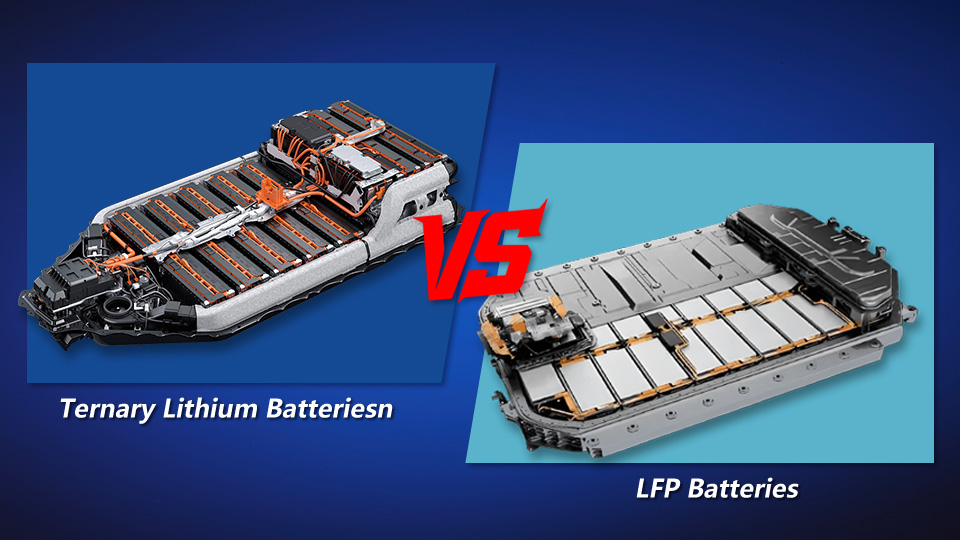

In the core battleground of new energy vehicles—the battery system—the comparison between ternary lithium (NCM/NCA) and lithium iron phosphate (LFP) chemistries is well understood. OEM choices reflect a strategic balance between performance, safety, and cost.

However, one decisive factor is often underestimated: the ultimate performance of a battery pack depends not only on cell chemistry, but also on the electrical interconnection network—the busbars and connection system. Selecting the right cells is only the first step; pairing them with the wrong “vascular system” can significantly undermine their inherent advantages.

Two Cell Chemistries, Distinct Demands on Interconnection

1. Ternary Lithium Batteries (NCM/NCA): Performance-Driven, Highly Sensitive to Efficiency

Core strengths:

High energy density (cell level ~200–300 Wh/kg; pack level typically 180–220 Wh/kg) enables long range and lightweight design. High power density supports strong acceleration and fast charging, with relatively better low-temperature performance.

Critical requirements for busbars:

-

Ultra-low resistance: Essential to fully realize fast charging and high-power output while minimizing losses and heat generation.

-

High-voltage insulation: Compatibility with 400 V and 800 V platforms demands higher dielectric strength and stricter creepage/clearance design.

-

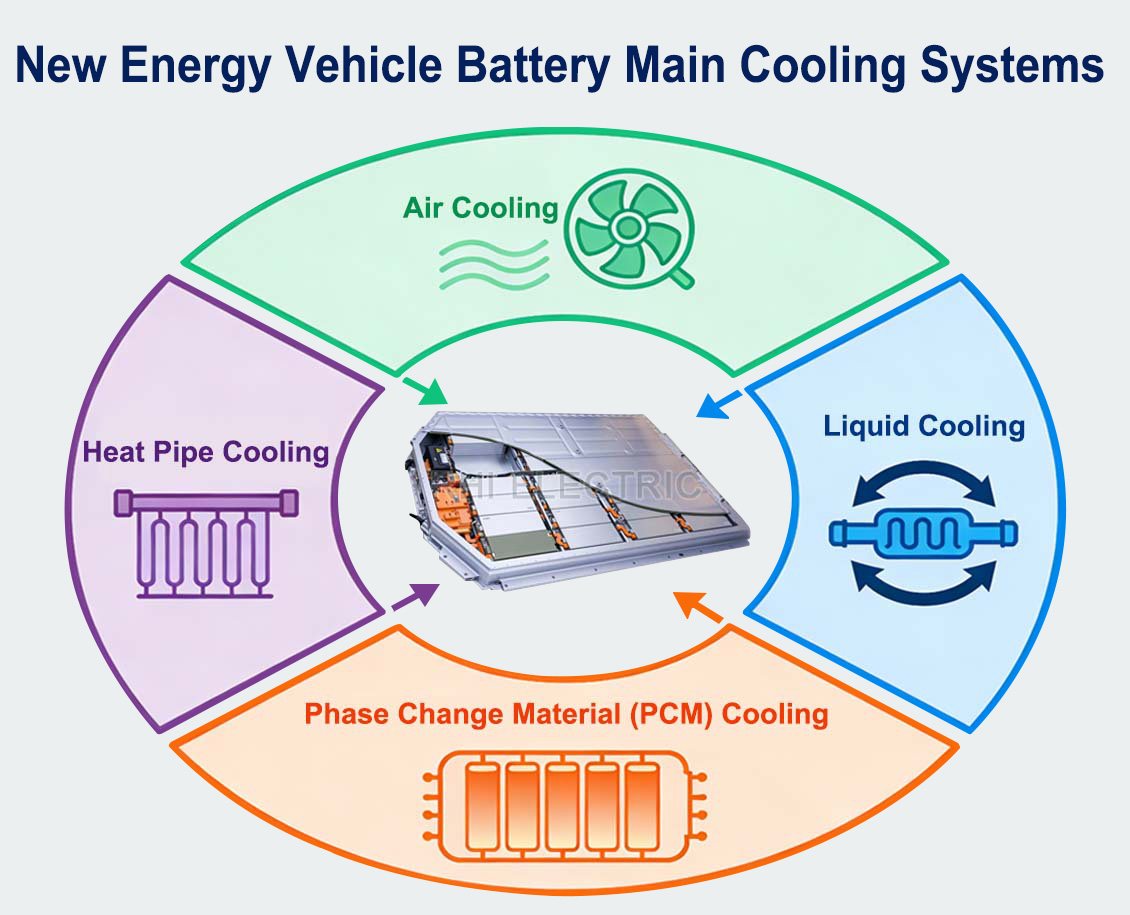

Precise thermal coordination: With lower intrinsic thermal stability, the interconnection system must generate minimal heat and integrate effectively with the battery thermal management system, acting as a controlled heat-transfer path.

2. LFP Batteries: Reliability-Focused, Highly Demanding on Long-Term Stability

Core strengths:

Excellent intrinsic safety, high thermal runaway threshold, and long cycle life (4,000–6,000+ cycles to 80% SOH). Structural innovations such as CTP and blade designs significantly improve system-level integration efficiency.

Rigid requirements for busbars:

-

High continuous current & creep resistance: To offset lower cell voltage and energy density, LFP systems often operate at higher sustained currents. Connections must resist metal creep and vibration-induced loosening over the vehicle lifetime.

-

Corrosion resistance & durability: Interface resistance must remain stable despite oxidation and electrochemical effects over long-term operation.

-

Cost and weight optimization: The interconnection solution itself must be cost-effective and contribute to overall vehicle lightweighting.

Busbars: Performance Enablers and Safety Barriers

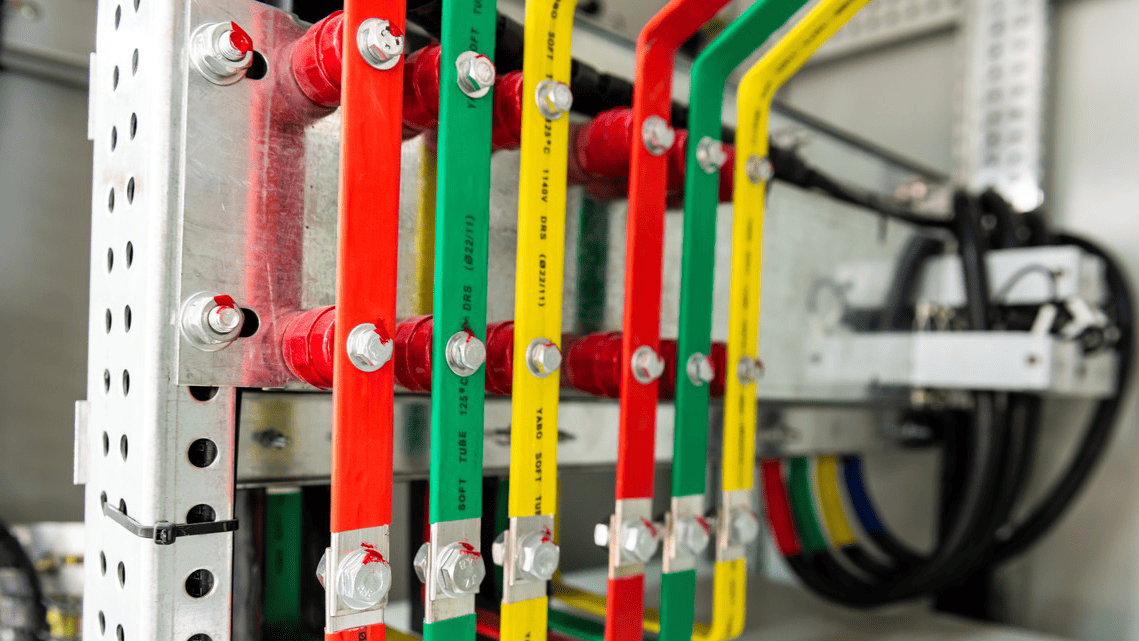

Cells store energy; busbars distribute it. Their design directly determines power loss, fast-charging sustainability, and whether the system’s weakest point emerges under extreme conditions.

Busbar Strategy for Ternary Lithium Packs: Conductivity, Heat, and High Voltage

-

Materials & processing: High-purity oxygen-free copper (T2) ensures baseline conductivity. Key contact areas use silver plating or thick nickel plating to reduce contact resistance and improve oxidation resistance.

-

High-voltage safety design: For 800 V+ systems, integrated injection molding or high-performance insulation films deliver higher dielectric ratings, better thermal performance, and stronger mechanical protection.

-

Thermal integration: Busbar geometry and layout are optimized to increase heat dissipation area or integrate thermal pathways, supporting overall pack thermal efficiency.

Busbar Strategy for LFP Packs: Current Capacity, Anti-Creep, and Cost Efficiency

-

Hybrid material solutions: Designs such as copper–aluminum composite busbars or copper at critical nodes with aluminium for long runs ensure electrical performance while achieving significant weight and cost reduction.

-

Anti-creep structural design: Special copper alloys, optimized bolt preload, and elastic compensation elements maintain stable contact pressure under long-term vibration and high current, preventing thermal runaway risks from loosening.

-

Enhanced protection & monitoring: Reinforced surface coatings and provisions for temperature sensing (e.g., NTC locations) improve reliability under sustained high-current operation.

Scenario-Based Interconnection: From Rigid Backbone to Flexible Joints

A professional interconnection solution adapts to different pack locations:

-

Rigid backbone (module-to-module, main circuits):

Low-resistance rigid copper busbars act as energy highways, prioritizing minimal voltage drop and high structural integrity. -

Flexible joints (cell-to-cell, vibration-critical zones):

Copper or aluminium laminated flexible connectors absorb assembly tolerances and dynamic loads, while their large surface area enhances natural heat dissipation—key to long-term reliability. -

Lightweight extensions (non-critical current paths):

After rigorous simulation and validation, copper–aluminium busbars can further reduce pack and vehicle weight.

Conclusion

Battery chemistry defines the engine type; busbars and interconnections define the transmission and chassis tuning. A high-performance battery system requires tight alignment between electrochemical potential and precise physical connectivity.

Cell selection sets the performance boundary, but busbar design determines whether that boundary is safely and reliably achieved. Understanding the distinct electrical, mechanical, and thermal requirements of different chemistries—and delivering precisely matched interconnection solutions—is essential to unlocking full battery pack potential.

RHI provides customized copper and aluminium busbar solutions for EV battery packs and energy storage systems, supporting NCM/NCA, LFP, and other chemistries with integrated electrical simulation, structural design, and scalable mass production. Contact RHI Team for your customized new energy battery connection solutions!