RHI's Modern Design and R&D Capabilities

As a leading new energy busbar manufacturer, RHI drives continuous innovation in design and development. With advanced technology, strong R&D, and a commitment to quality, we ensure our products meet the highest standards.

Advanced Technology Application

RHI utilizes advanced automatic welding equipment, including laser and atomic welding machines, to provide cost-optimized, lightweight composite busbars using aluminum-to-aluminum and copper-to-aluminum welding techniques. We excel in high-temperature insulation with composite mica and ceramic tapes, while our automated winding machines ensure efficient and high-quality production.

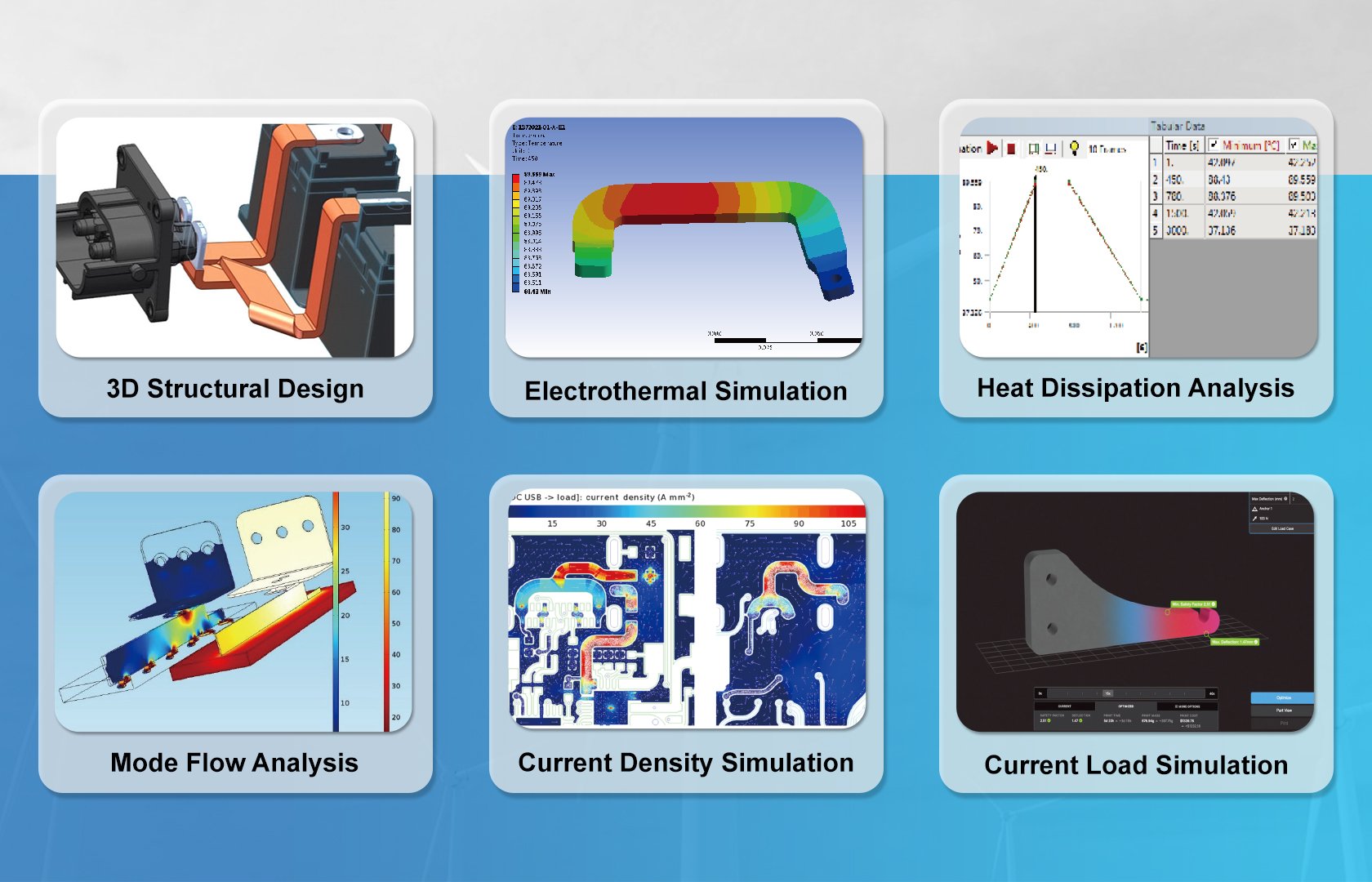

Advanced R&D Capabilities

Our R&D team leverages advanced design software and tools such as 3D structural design, electrothermal simulation, mold flow analysis, and power load simulation. These tools allow us to optimize busbar designs, predict performance, and ensure exceptional product reliability in real-world applications.

Comprehensive Testing Facilities

RHI's laboratory is equipped with advanced devices such as a salt spray tester, metallographic analyzer, and constant temperature and humidity chamber. These allow us to test for salt spray corrosion, hardness, pull-out force, contact resistance, and bending performance, ensuring our products meet industry quality standards in both design and production.

.jpg)

Expert Team & Comprehensive Management

Our team comprises over 70 professionals, including experienced project managers, R&D managers, and PMC managers. With expertise in project planning, R&D management, and production control, our team excels in comprehensive project management, including schedule control, resource allocation, and risk management.

Stringent Quality Control Processes

RHI enforces rigorous quality control throughout design and manufacturing. APQP and PPAP are standardized quality control processes used for project planning and mass production validation, ensuring feasibility and reliability from the start. In production, CCD inspections capture micro-defects invisible to manual visual checks, providing precise and repeatable results for higher accuracy and consistency. From material sourcing to final inspection, every stage is monitored to ensure compliance with international standards and customer requirements.

.jpg)

Innovation & Intellectual Property

RHI holds 26 patents, including 2 invention patents, 6 design patents, and 18 utility model patents, with several more pending. These patents underscore our leadership in technological innovation and intellectual property protection, highlighting our strengths in busbar design and R&D.