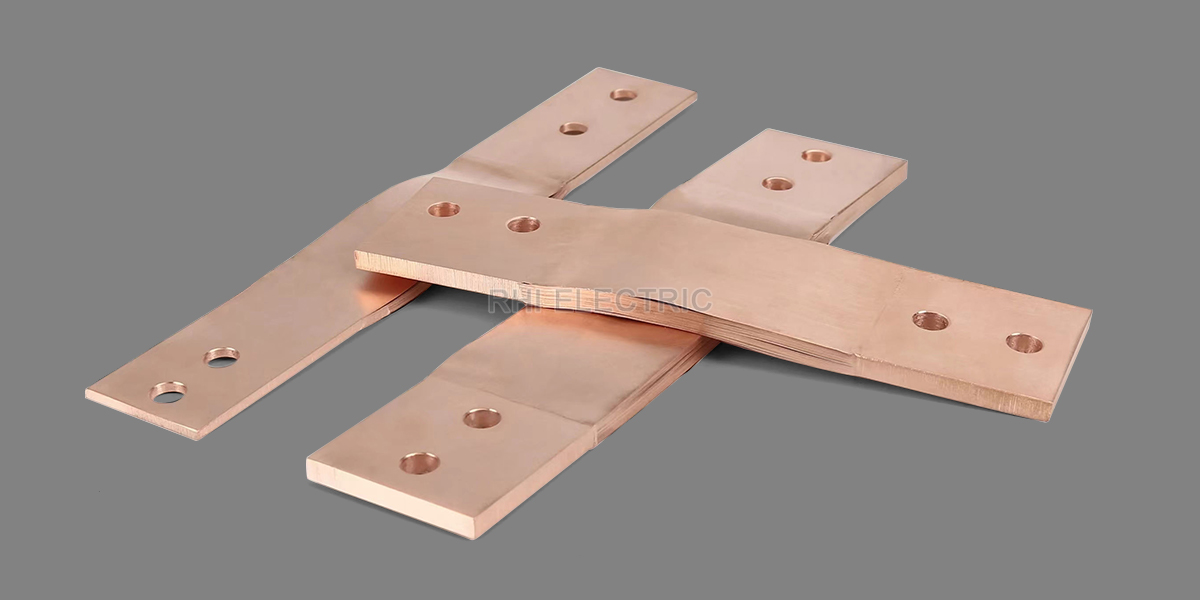

HV Busbar Flexible Copper Busbar

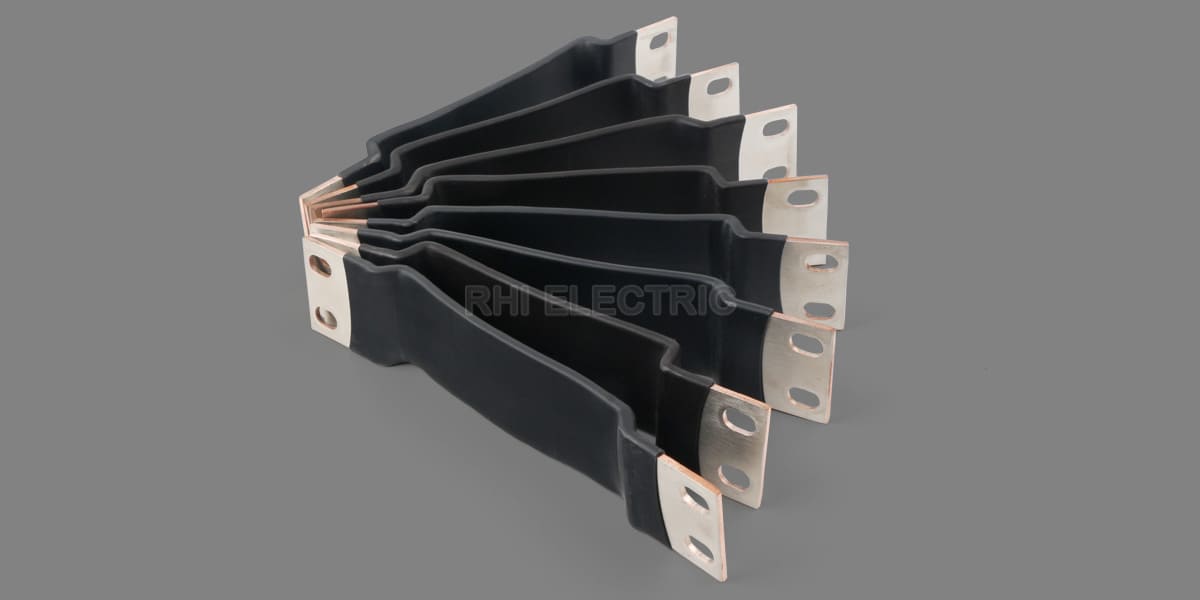

Designed for high-reliability, low-impedance battery interconnections, this flexible copper busbar uses T2 copper (≥98% IACS). Its laminated copper foil structure provides effective heat dissipation and vibration damping, ensuring long-term stability under demanding conditions. Easy to install and space-efficient, the copper busbar supports optional insulation for enhanced electrical safety in high-voltage battery modules and ESS interconnections.

Designed for high-reliability and low-impedance connectivity in power battery systems, the HV busbar is crafted from T2 copper with conductivity exceeding 98% IACS. Its multi-layer ultra-thin copper foil structure (0.1mm), formed through diffusion welding, provides efficient heat dissipation, vibration absorption, and mechanical stress relief, ensuring long-term structural integrity and electrical performance.

Highly flexible and easy to install, the copper busbar optimizes layout space and reduces system cost. Available with insulation options such as heat-shrink tubing or PVC dip coating insulation, the battery busbar meets diverse electrical safety needs. It withstands temperatures from -50 °C to 125 °C and DC 4000 V for 1 minute, making it an ideal interconnect solution for high-voltage battery modules and energy storage systems.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Working Temperature | Insulation solution | Conductor Material |

| Values | 4000 V DC, 1 min | Qualified | UL94 V-0 | -50~125 °C | Heat-shrink insulation | T2 Copper |

Advantages

- Dynamic Stress Adaptation: Excellent flexibility and displacement compensation absorb deformation caused by cell expansion, vibration, and thermal cycling, preventing stress concentration and connection failure.

- High Vibration and Fatigue Resistance: Laminated multi-layer structures provide inherent damping, reducing high-frequency vibration and improving long-term connection reliability.

- High Installation Tolerance: The flexible structure accommodates positional and dimensional tolerances, easing alignment requirements, improving assembly efficiency, and reducing installation stress.

- Optimized System Integration: Supports complex layouts through bending or folding, enabling compact routing while reducing system weight and supporting higher battery pack (PACK) energy density.

- Thermo-Mechanical-Electrical Synergy: Material and structural design ensure conductivity while enhancing heat dissipation and mechanical buffering, meeting multi-physics demands in EV and energy storage applications.

Flexible busbars have therefore become a key interconnection solution for high-reliability battery modules, energy storage systems, and vibration-resistant equipment.

RHI Manufacturing Strength

With 10 years of expertise in the new energy sector, RHI operates a 30,000+ m² modern manufacturing facility and specializes in customized, high-performance battery interconnection solutions for global customers. The company is equipped with fully automated dip-coating, extrusion, welding, and 3D bending lines, supported by six-axis robotic workshops, a precision tooling R&D center, CCD automated inspection, and dedicated testing laboratories.

Certified to IATF 16949, ISO 14001, and ISO 45001, RHI’s products comply with EU environmental regulations and meet UL94 V-0 flame-retardant standards. Backed by rigorous process and quality control, RHI has earned inspection-exempt supplier status from multiple OEMs and provides reliable electrical interconnection solutions for industry leaders such as CATL, the Renault–Nissan Alliance, and Trinasolar. Supported by an experienced engineering team and professional service, RHI ensures precise requirement matching and efficient project execution for customers worldwide.