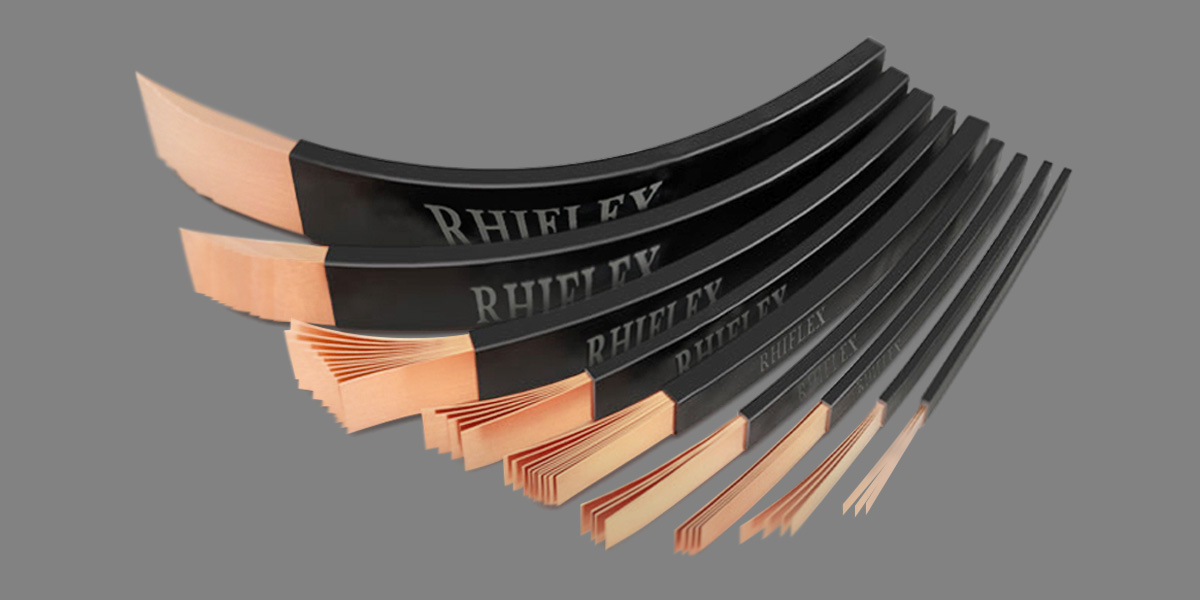

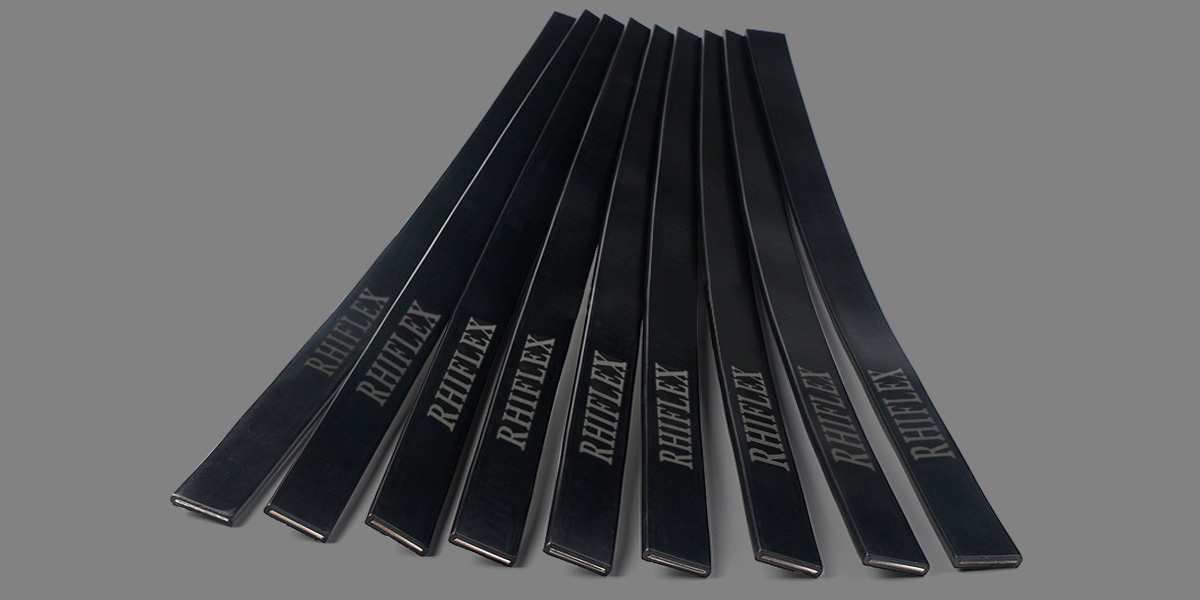

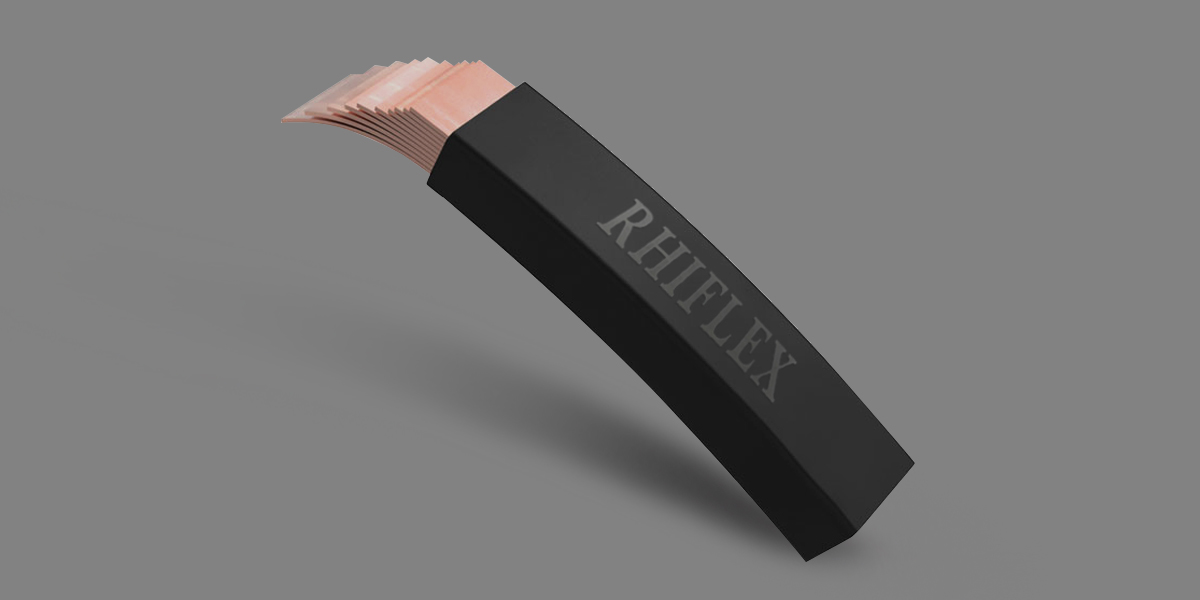

Insulated Flexible Copper Busbar for Panel Boards

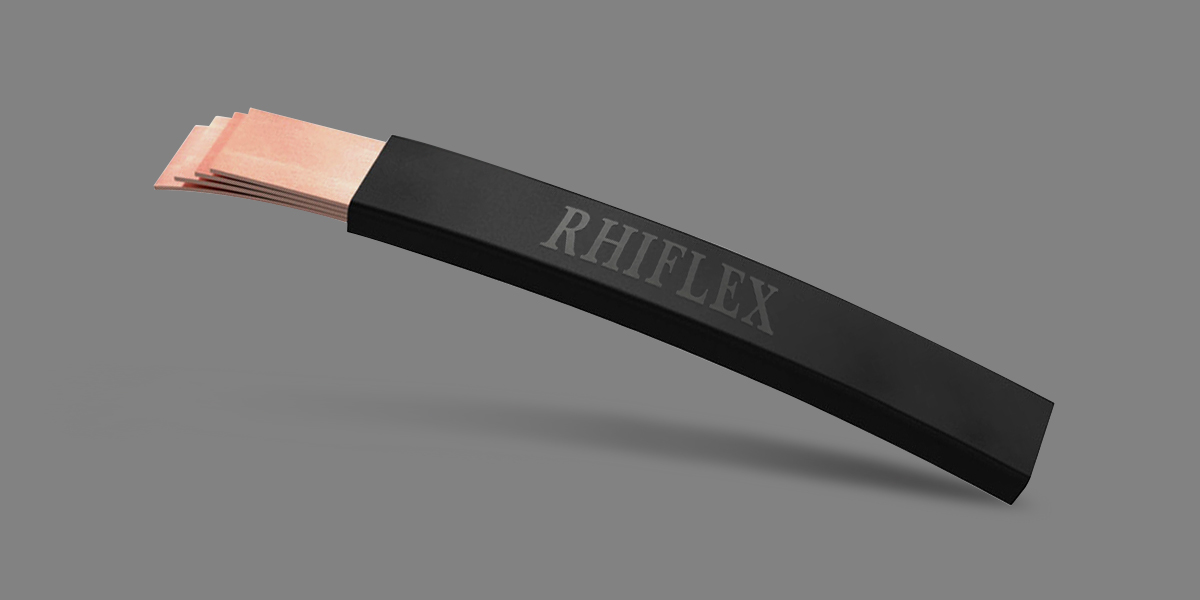

Extruded insulated busbars are flexible conductive components with excellent conductivity and insulation. The seamless insulation layer forms a smooth, uniform coating over laminated copper conductors, ensuring long-term electrical isolation and protection. Highly flexible and space-efficient, these copper busbars are ideal for high-voltage distribution, improving assembly efficiency and reducing maintenance costs.

Made from high-conductivity copper or aluminum, these extruded insulated busbars combine stable electrical performance with high flexibility. The continuous extrusion process applies a uniform PVC insulation layer, enabling one-step forming, strong abrasion resistance, and reliable durability. They are widely used in high/low-voltage energy storage systems, switchboards, and panel boards.

Features

-

Flexible & Easy to Bend: Supports small-radius bending for compact electrical layouts.

-

Stable Insulation: Seamless PVC coating ensures consistent dielectric strength and prevents short circuits.

-

Customizable: Conductor size, insulation thickness, and shape can be tailored for different applications.

|

Parameter |

Copper Conductivity |

Insulating Material |

Dielectric Strength |

Operating Temperature |

Operating Voltage |

Flame Retardant Rating |

Environmental Protection |

|

Values |

≥57MS/m |

PVC |

20KV/mm |

-40℃~105℃ |

DC 1500V |

UL94 V-0 |

RoHS |

Product Details

|

Conductor Material: |

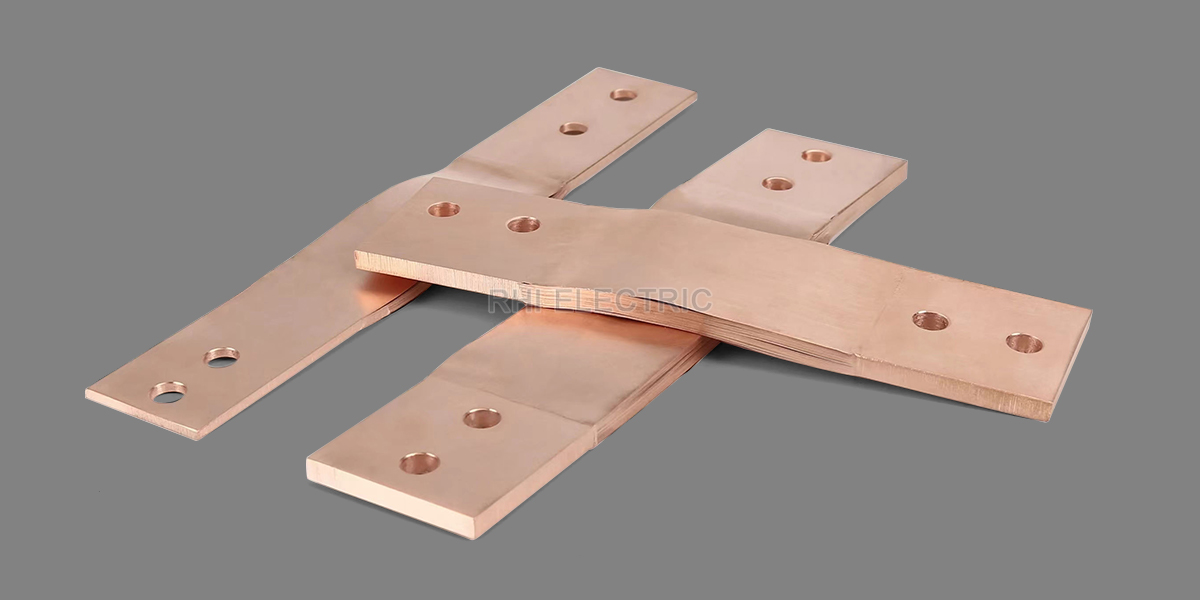

Cu Strip or Al Strip T2 Copper Aluminium (1060 ) Other materials customizable. |

|

Surface Treatment: |

Bare, Tin Plating, Nickel Plating |

|

Application: |

EV Battery Pack Connections, Energy Storage Systems, Electric Cabinets, Panel Boards |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Quality Management Standard: |

Meet Auto Industry IATF16949 |

|

Eco-friendly Certificate: |

RoHS |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

Advantages

-

Continuous Extrusion Forming: High-efficiency one-pass molding reduces labor and supports large-scale production.

-

Small Bending Radius: Maintains insulation integrity during tight bends, suitable for dense system designs.

-

Environment-Compliant PVC: Meets environmental standards and offers reliable heat resistance and aging performance.

-

High Insulation Reliability: Provides strong electrical protection for high-voltage operation.

-

Durable Mechanical Strength: Wear-resistant, shock-resistant, and ideal for battery module and PDU interconnections.

-

One-Step Production: Conductor feeding and insulation extrusion completed simultaneously, improving consistency and lowering manufacturing cost.