Copper-Aluminium Busbars for EV Applications with Friction Welding

Copper-Aluminium Busbars with Friction Welding Combining copper's high conductivity with aluminium's lightweight and cost advantages, these electrical busbars ensure reliable high-current performance while reducing system weight. Ideal for EV battery packs, motor control systems, and charging interfaces, etc.

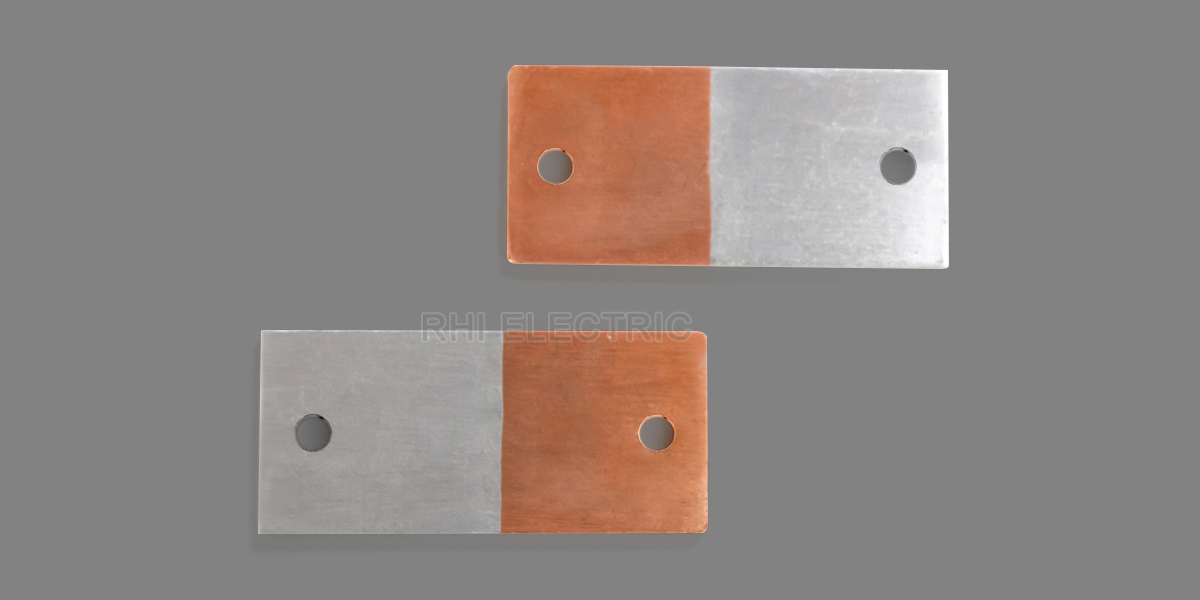

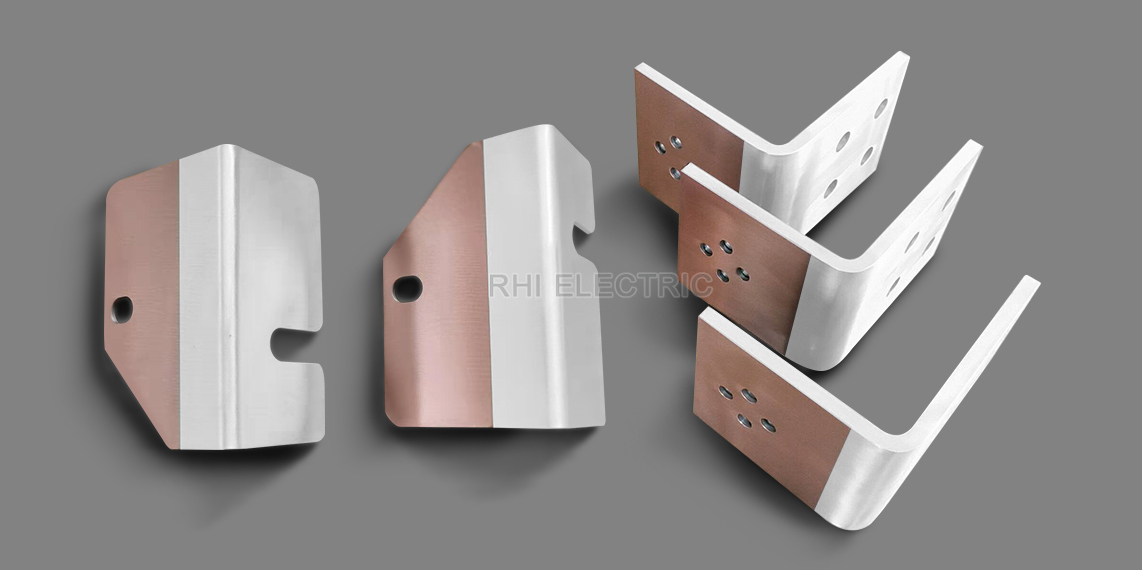

Friction-Welded Copper-Aluminium Busbars

Friction-welded copper-aluminium busbars combine copper's high conductivity with aluminium's lightweight and cost advantages. The solid, low-resistance weld ensures stable high-current transmission while reducing system weight and manufacturing costs. Widely used in EV battery packs, motor control systems, charging interfaces, and energy storage equipment, these busbars deliver excellent performance under high-current, high-reliability conditions, optimize thermal management, extend system life, and offer a cost-effective alternative to all-copper busbars.

Specifications

Material: T2 Copper + 1060 Aluminium

Welding Process: Friction Welding

Electrical Conductivity: ≥62% IACS

Tensile Strength: ≥76 MPa

Operating Temperature: ≤150℃

Copper-Aluminium Busbar Applications

New Energy Vehicles (EV/HEV/PHEV)

- High-voltage interconnections within battery packs, ensuring low resistance and thermal stability in confined spaces.

- Interfaces between motor controllers and battery systems, requiring high current-carrying capacity and vibration resistance.

- Fast-charging inlets and outlets, where copper-aluminum busbars help reduce system weight while maintaining conductivity.

Energy Storage Systems (ESS)

- Connections between battery clusters and main busbars, designed to meet GB/T 29321 safety and performance requirements.

- Interfaces between energy storage batteries and inverters, supporting stable DC/AC conversion under fluctuating loads.

Power Distribution and Industrial Equipment

- Busbars in high-voltage switchgear and distribution cabinets, compliant with GB/T 7251 for low-voltage assemblies.

- Interconnections for wind and photovoltaic inverters, providing corrosion resistance and long-term current stability in outdoor environments.

Charging Infrastructure

- Internal high-current connections for DC fast-charging stations, meeting national EV charging standards and enabling safe, efficient energy transfer.

About RHI

RHI specializes in copper and aluminium busbars for new energy batteries. Operating a 30,000 m² plant with 120+ quality staff and 100+ R&D engineers, RHI features advanced extrusion, 3D CNC bending, injection molding, six-axis robotics, precision tooling, and testing facilities, enabling synchronous design and development with OEMs.