Understanding Electrical Busbars and the Essential Role of Busbar Covers in Power Systems

Learn how electrical busbars and protective covers enhance power system safety, reduce faults, and ensure efficient current distribution in modern grids.

What Is an Electrical Busbar?

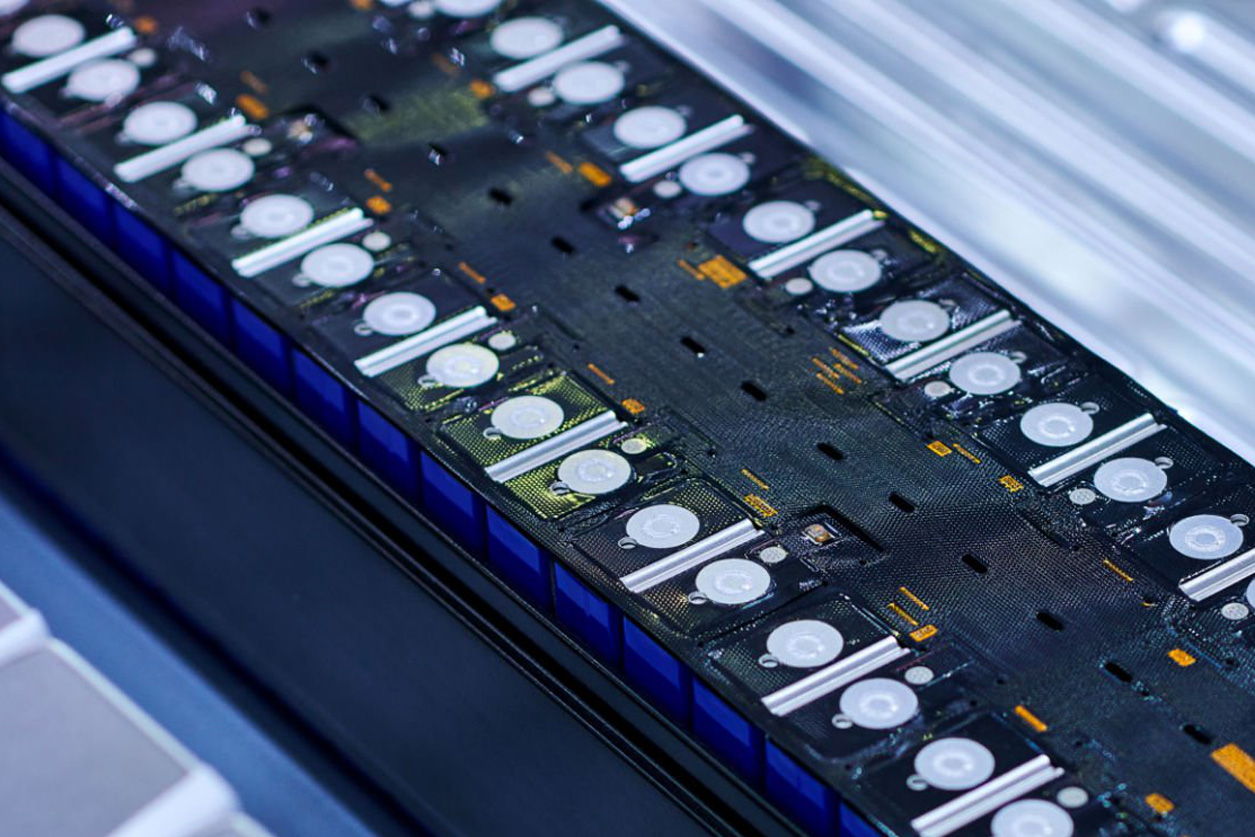

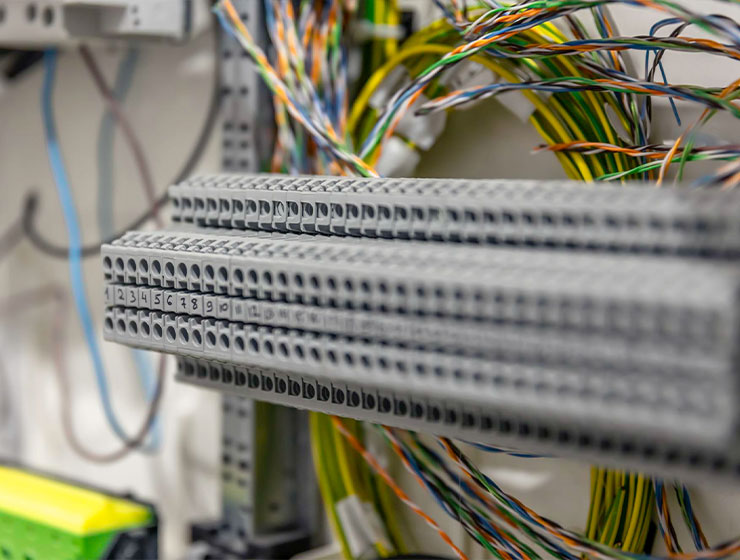

In modern electrical engineering, the electrical busbar is a foundational component used for conducting and distributing electric power within switchboards, substations, and distribution systems. Simply put, it is a metallic strip or bar, typically made of copper or aluminum, that carries large currents. Its primary purpose is to connect incoming and outgoing electrical lines in a neat, efficient, and safe manner. The electrical busbar definition goes beyond being just a conductor — it is a key architecture that ensures energy flows reliably within power networks while minimizing space, reducing wiring complexity, and improving heat dissipation.

Why Are Busbar Covers So Important?

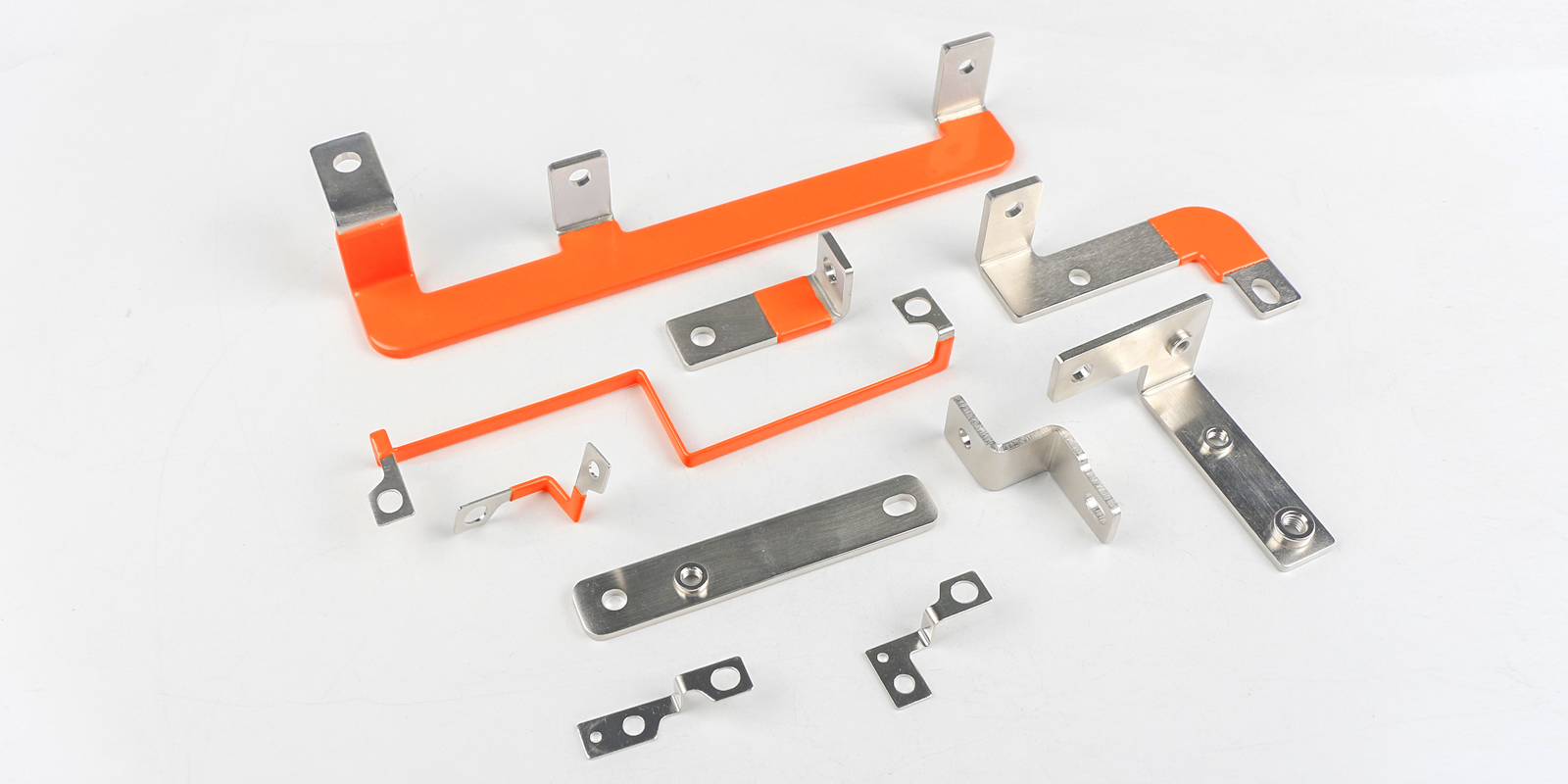

While busbars are essential for electrical transmission, they also pose safety hazards if left unshielded. This is where electrical busbar covers come into play. These covers, often made from high-durability PVC or flame-retardant polycarbonate, serve as insulation and protection from accidental contact, arcing, and dust accumulation. Busbar covers play a crucial role in preventing electrical accidents, especially in industrial control panels and power cabinets where human interaction or maintenance is frequent. RHI Electric offers a wide range of customized busbar insulation solutions designed for safety compliance and operational durability.

Applications of Busbars and Their Protective Covers

From power generation plants to industrial machinery and renewable energy systems, electrical busbars are widely used in environments where current load is high and space optimization is key. Busbars improve system reliability by reducing the number of connection points, which in turn lowers the chances of overheating or failure. Electrical busbar covers, meanwhile, provide consistent dielectric strength and can be engineered to fit different shapes and installation needs — straight runs, bends, T-junctions, or enclosed compartments. RHI Electric's solutions are designed to support even the most complex energy infrastructure with precision-molded protective accessories.

How RHI Electric Delivers Value Through Innovation

With over 15 years of experience in electrical insulation and power connection systems, RHI Electric has emerged as a trusted name in the global market. The company designs and manufactures electrical busbar covers that meet international standards such as UL94 V-0 flame retardancy, high mechanical strength, and easy installation. RHI’s product lineup includes heat-shrinkable, wrap-around, and transparent covers for visual inspection. Each product is tested for voltage endurance and thermal resistance, ensuring that clients in automotive, solar, telecom, and energy industries receive long-term protection with minimal maintenance.

Final Thoughts: A Small Component with a Big Impact

Understanding the definition of an electrical busbar and the protective function of its covers is crucial for anyone involved in system design, installation, or maintenance. Even though these components may seem small compared to transformers or generators, their role in enhancing operational safety and energy efficiency cannot be overstated. As power systems evolve toward higher voltages and compact layouts, solutions like RHI Electric’s busbar covers will become increasingly vital. If you're looking for a reliable partner in electrical insulation and power distribution, RHI Electric provides performance-driven solutions tailored to your project’s technical demands.