Understanding Electrical Busbar Price – Factors, Trends, and Smart Purchasing

Explore key factors affecting electrical busbar prices, market trends, and tips for smart purchasing to optimize cost and quality in power systems.

Introduction: Why Electrical Busbar Pricing Matters

In modern electrical distribution systems, busbars play a crucial role in ensuring efficient, safe, and scalable power delivery across industrial, commercial, and large residential applications. However, many buyers often wonder why electrical busbar price fluctuates and what factors impact their cost. Understanding these factors helps project planners, facility managers, and procurement teams make informed purchasing decisions that align with project budgets without compromising quality and performance. RHI Electric, a professional busbar system manufacturer, offers high-quality electrical busbars at competitive pricing, making them a trusted partner for projects worldwide.

What Influences Electrical Busbar Price?

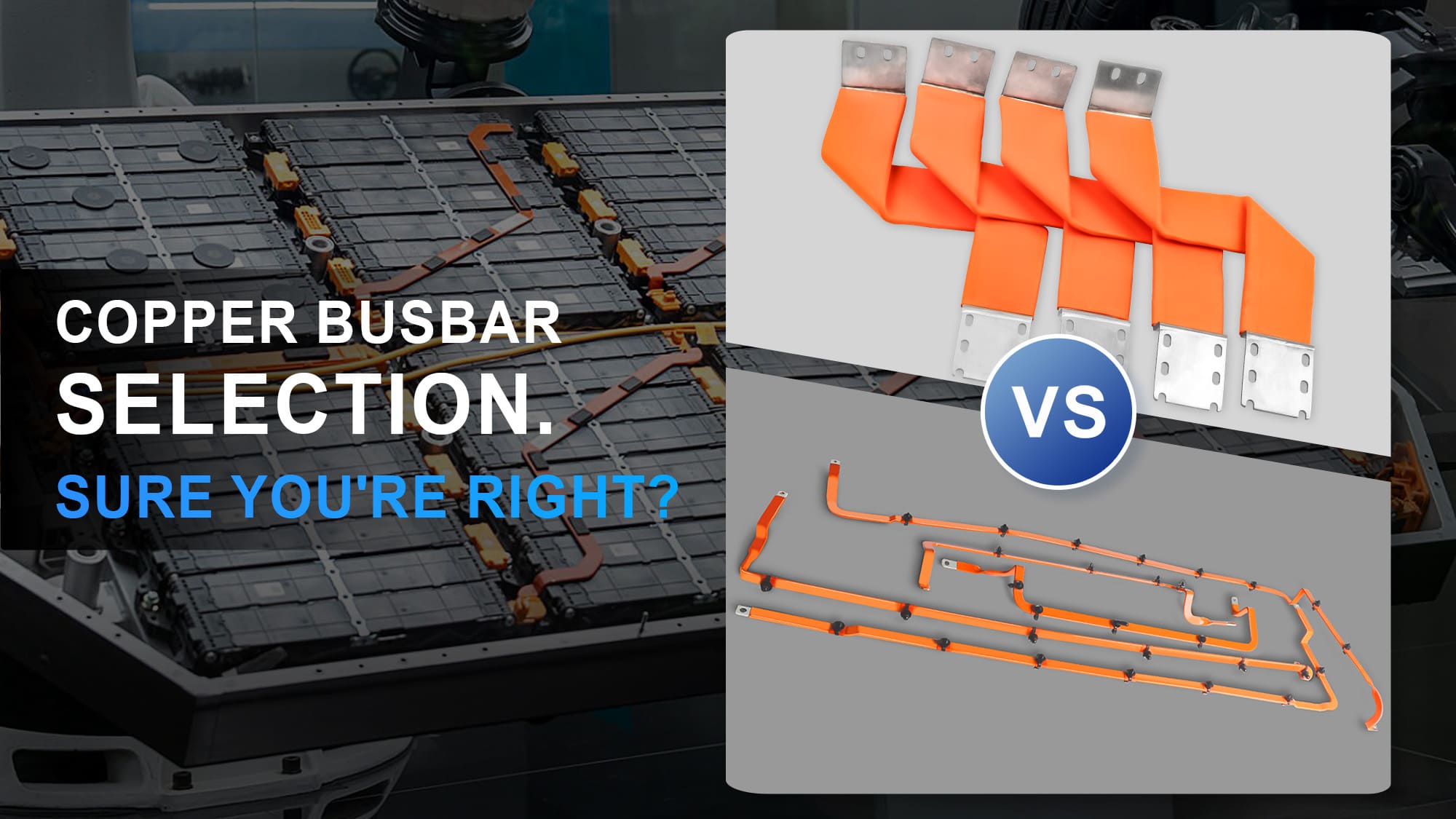

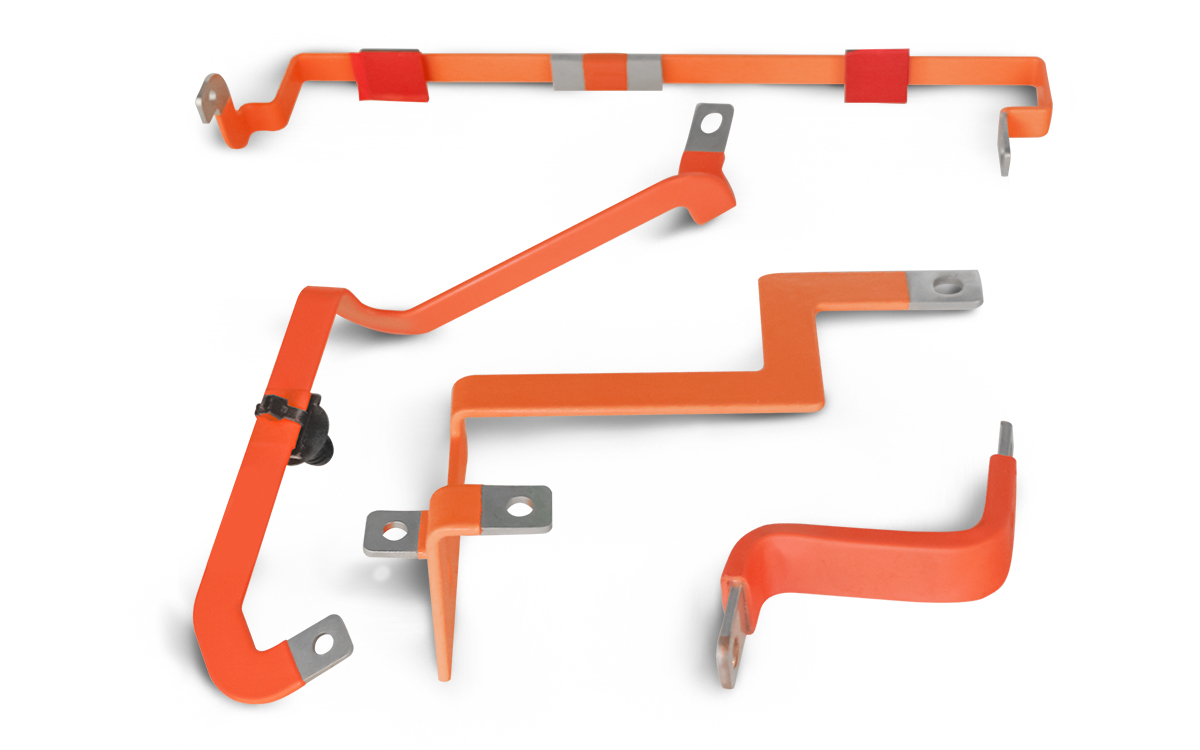

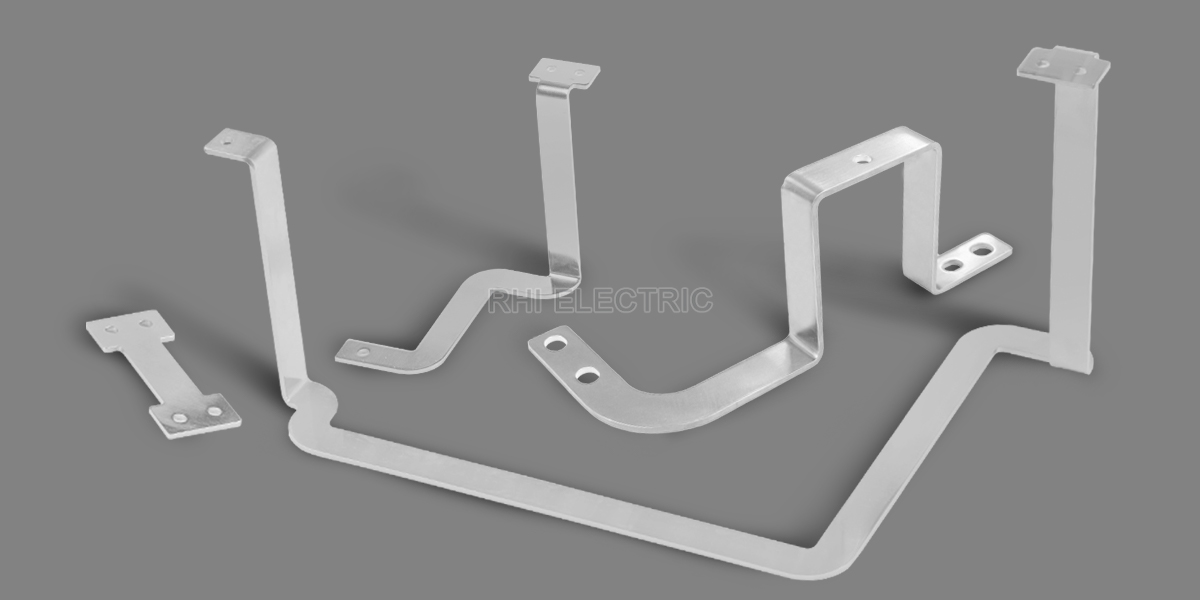

The price of an electrical busbar is influenced by multiple factors, including material type (copper vs. aluminum), conductor size, insulation type, manufacturing complexity, and compliance with standards. Copper busbars are more expensive due to higher conductivity and corrosion resistance, while aluminum busbars offer a lightweight, cost-effective alternative for many applications. Busbars requiring advanced insulation or epoxy coatings for outdoor or harsh environments will typically cost more. Additionally, prices may vary with the customization level, as tailored designs for specific applications require engineering resources and specialized fabrication.

Market Trends Driving Busbar Pricing

With the global focus on renewable energy, smart grids, and energy-efficient systems, the demand for high-quality electrical busbars has risen significantly. Supply chain fluctuations for copper and aluminum, environmental policies, and production energy costs also directly affect electrical busbar price in different regions. RHI Electric leverages its advanced manufacturing facilities and raw material sourcing network to stabilize costs while ensuring high product standards, allowing customers to manage project budgets without unexpected price spikes.

Balancing Cost with Quality and Performance

While cost is an important factor, choosing the lowest-priced busbar without considering quality can result in higher long-term operational costs, including maintenance, energy losses, and system failures. It is crucial to select busbars that meet required standards, ensure low power loss, and provide safe distribution under high-load conditions. RHI Electric ensures every busbar undergoes rigorous quality control and testing, balancing cost-effectiveness with high reliability and performance for critical power distribution systems.

How RHI Electric Provides Cost-Effective Busbar Solutions

RHI Electric specializes in the design and manufacturing of electrical busbars that cater to a variety of industries, including renewable energy projects, data centers, commercial buildings, and industrial facilities. By leveraging in-house engineering and automated production, RHI offers competitive electrical busbar price while maintaining flexibility for custom projects. Customers benefit from shorter lead times, tailored design support, and transparent pricing structures, ensuring projects remain within budget while meeting all safety and efficiency requirements.

Future Outlook: Electrical Busbar Market Pricing Trends

As industries shift toward green energy and digitalized power distribution, the demand for reliable, high-efficiency busbar systems will continue to grow. While raw material price volatility will continue influencing the market, technological advancements and economies of scale will help stabilize electrical busbar price for large-scale projects. RHI Electric is investing in sustainable production and advanced manufacturing to ensure customers receive reliable, cost-effective solutions for the evolving market landscape.

FAQ: Electrical Busbar Price

Q1: What factors determine the price of an electrical busbar?

Material type, size, insulation, compliance with standards, and customization levels directly impact pricing.

Q2: Are copper busbars more expensive than aluminum busbars?

Yes, copper busbars generally cost more due to higher conductivity and corrosion resistance.

Q3: Can I get customized busbar designs from RHI Electric?

Yes, RHI Electric provides customized busbar solutions based on project requirements while maintaining cost-efficiency.

Q4: How can I get a quote for electrical busbars?

Visit RHI Electric or contact their sales team to discuss your project and get a transparent quote.

Q5: Why is it important not to choose the cheapest option blindly?

Low-quality busbars can increase operational costs through power losses and potential failures, making quality and efficiency important for long-term savings.