Copper Busbar Joint Overcurrent: Key Issues and Engineering Solutions

With new energy technologies rapidly iterating, energy storage systems are advancing toward high energy/power density. Industry trends indicate the overcurrent issue at copper busbar lap joints has become a critical bottleneck for new energy development, urging innovative solutions.

Overcoming Overcurrent Challenges at Copper Busbar Joints in New Energy

As the new energy sector continues its rapid evolution—from the powerful drive systems of electric vehicles to the stable energy hubs of large-scale storage stations—busbars serve as critical "bridges" in power transmission. Their performance directly impacts the stability and safety of the entire system. Copper busbars, known for their excellent electrical conductivity and mechanical strength, are widely used across the industry. However, a persistent challenge often overlooked lies in the overcurrent capacity at busbar joints—an invisible yet serious risk to system efficiency and reliability.

1. A Deep Dive into Overcurrent Issues at Busbar Joints

(1) Theoretical Current-Carrying Capacity vs. Real-World Limitations

From an electrical engineering perspective, a busbar’s current-carrying capacity is not a linear function—it’s influenced by multiple factors. According to Joule’s law (Q = I²Rt), current passing through a conductor generates heat due to resistance. For safe operation, the maximum allowable current must ensure that the resulting temperature remains within limits to avoid degradation or safety hazards.

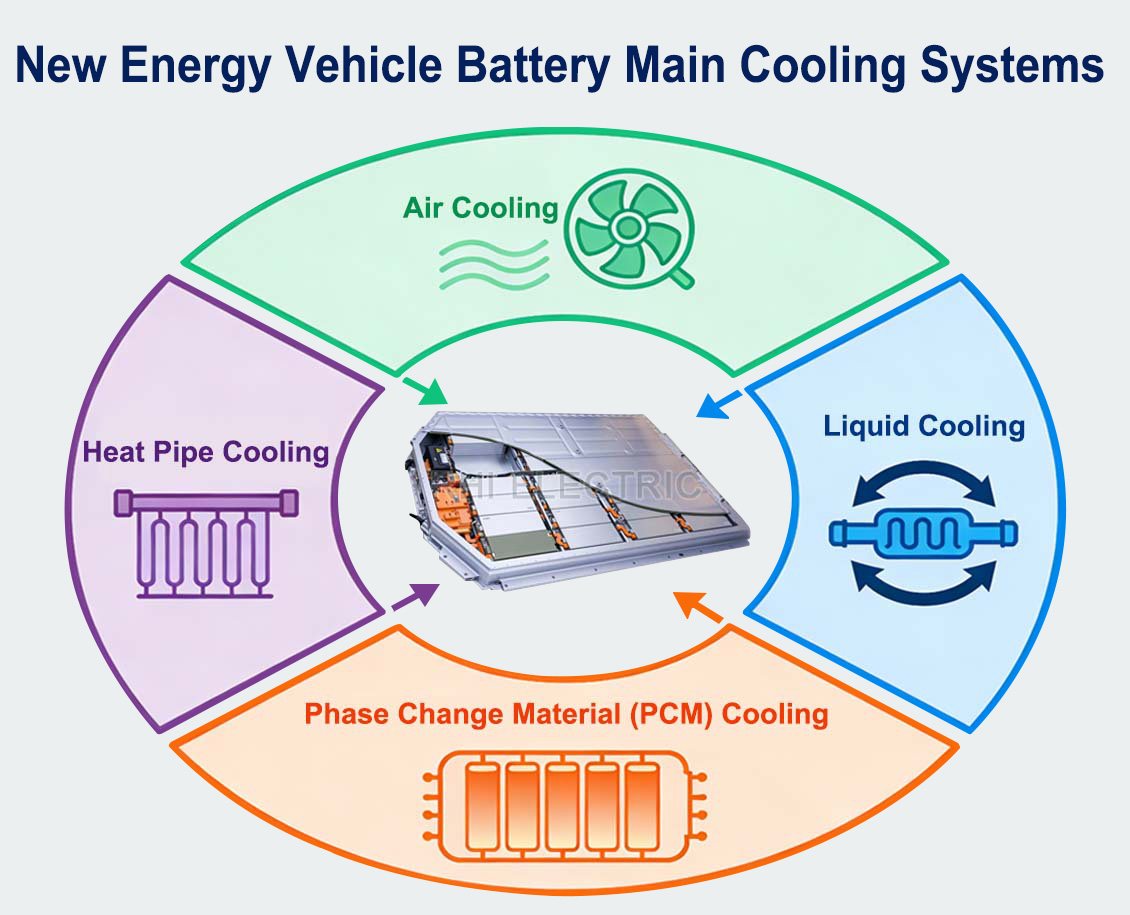

At the copper busbar joint, things become more complex. Contact resistance acts as an additional heat source, increasing the risk of localized overheating. Standards like GB/T7251.1 (equivalent to IEC 61439-1) specify that under ideal conditions—excluding contact resistance, insulation supports, or coatings—the maximum permissible temperature rise for copper busbars should not exceed 105K. Considering an average ambient temperature of 35°C, the maximum operating temperature for conductors is 140°C. Beyond this, copper undergoes annealing, significantly reducing mechanical strength and jeopardizing its structural role. Excess heat can also compromise insulation supports, adjacent components, and even pose fire risks.

(2) Current Surges and Harsh Operating Conditions

New energy battery systems experience frequent and dramatic current fluctuations. For instance, a typical EV battery system operates around 200A, but during fast charging, peak current may reach 600A for up to 15 seconds. According to short-time withstand current formulas (with a copper factor of 13), the minimum cross-sectional area required is:

S = (I/13) × √t

However, real-world environments introduce additional challenges—high temperatures raise copper resistance, while high humidity accelerates oxidation, increasing contact resistance. These environmental factors must be accounted for in design.

(3) Rising Industry Demands and Emerging Challenges

Driven by innovation, energy storage systems are moving toward higher energy and power densities. This translates into significantly increased charge throughput via busbars. According to leading market research, battery busbar current-carrying demands in energy storage systems are expected to grow by 30%–50% within the next five years. Similarly, the push for longer EV driving ranges means battery systems must handle increasingly intense charge-discharge cycles. These trends point to one conclusion: overcurrent performance at copper busbar joints is a growing bottleneck that demands advanced solutions.

2. RHI Electric: Expert Solutions to Overcurrent Challenges

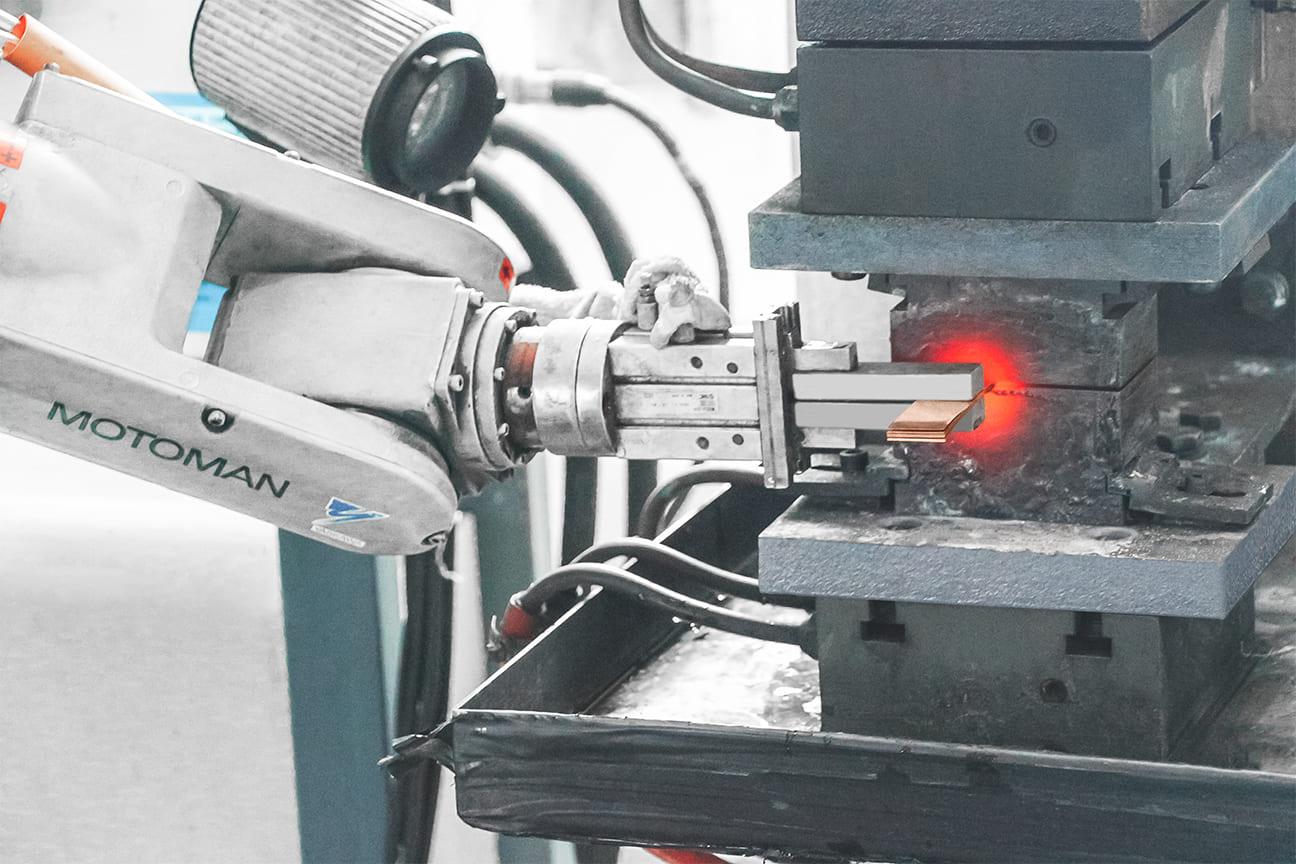

(1) Advanced Manufacturing Capabilities: The Backbone of Busbar Quality

As a long-standing specialist in battery connection technologies, RHI has deep expertise in busbar manufacturing. With over 30 high-performance polymer welding units and multiple automated welding lines, our facilities can handle a wide range of materials—from traditional copper-to-copper welds to complex copper-aluminum composites and rigid-flex combinations.

At the joint welding stage, we precisely control key parameters such as temperature, duration, and pressure to minimize contact resistance. This ensures efficient current transmission and significantly boosts the overall current-carrying capacity of our busbars, even under high-load or temperature-fluctuating conditions.

(2) Customized Busbar Solutions for Diverse Applications

Understanding the diversity of application scenarios, RHI provides tailor-made busbar designs based on each customer’s electrical, environmental, and spatial requirements. Our experienced engineering team uses simulation tools to optimize current-carrying capacity, thermal performance, and mechanical strength.

For high-current surge environments, we increase cross-sectional area or adopt parallel joint designs. In space-constrained scenarios, we implement compact layouts that maximize performance without sacrificing space efficiency.

(3) Strict Quality Control Ensures Long-Term Performance

RHI maintains a comprehensive quality control system that covers the entire manufacturing process. We rigorously select raw materials, conduct multiple rounds of purity and conductivity testing, and reject any materials that fail to meet our standards for high-purity, low-impurity copper.

During production, CCD vision systems inspect busbar dimensions and surface quality, while precision resistance testers continuously monitor joint resistance. Any deviation triggers alarms and immediate corrective action. Before delivery, all busbars undergo extensive simulations of real-world conditions—including overcurrent shock, temperature cycling, and long-term aging tests—to ensure consistent performance.