Understanding Electrical Busbars and the Role of Busbar Covers in Power Safety and Efficiency

Learn how electrical busbars and protective busbar covers enhance power distribution safety, efficiency, and reliability in modern electrical systems.

Introduction: The Backbone of Electrical Distribution Systems

In the complex world of electrical engineering, busbars are often the unsung heroes. Found in everything from industrial panels to high-voltage switchgear, busbars serve as the main arteries of power distribution, ensuring efficient and stable energy flow across systems. Yet despite their essential function, busbars come with inherent safety and performance challenges—this is where electrical busbar covers come into play.

Understanding what busbars are and why protective covers are essential can help engineers, technicians, and even commercial building owners make informed decisions about system safety, compliance, and longevity.

What Is an Electrical Busbar? (Electrical Busbar Definition)

An electrical busbar is a metallic strip or bar, usually made of copper or aluminum, used to conduct electricity within switchboards, distribution boards, and other electrical apparatus. Its primary function is to carry high currents safely and efficiently between incoming and outgoing circuits.

Busbars are valued for their low impedance, compact design, and flexibility. Instead of using multiple cables to distribute electricity, a single busbar can handle large currents, making it ideal for space-constrained installations.

· A key characteristic of busbars is their ability to reduce energy loss, voltage drops, and heat generation due to their large surface area and solid construction.

Busbars also offer superior mechanical strength, which is important in environments that require long-term reliability. Whether in substations or data centers, busbars provide a robust solution for uninterrupted power delivery.

The Function and Importance of Electrical Busbar Covers

While busbars themselves are highly efficient conductors, their exposed surfaces pose significant safety risks. Electrical faults, arc flashes, and accidental human contact are all potential hazards in systems where busbars are left uncovered. This is why electrical busbar covers are essential.

Busbar covers act as insulating barriers, preventing direct contact with live components and reducing the likelihood of short circuits. In addition to enhancing personnel safety, they also improve the durability of the busbar by protecting it from dust, moisture, and corrosive elements in harsh environments.

Modern busbar covers are made from high-grade insulating materials such as polycarbonate, PVC, or silicone. These materials are flame-retardant, UV-resistant, and capable of withstanding high temperatures—ideal traits for demanding industrial settings.

Applications in Industrial and Commercial Settings

Busbar systems, complete with protective covers, are commonly found in a wide variety of settings. From manufacturing plants and power stations to commercial buildings and transport infrastructure, busbars enable seamless power flow and compact system design.

In these environments, electrical busbar covers are not optional—they are critical for meeting international safety standards such as IEC 61439 or UL 857. Any deviation from proper insulation and spacing can lead to operational downtime, equipment failure, or worse, injury to personnel.

Furthermore, in control cabinets and motor control centers (MCCs), compact busbar arrangements with precision-fitted covers offer significant space savings and thermal advantages, especially in high-current applications.

Benefits of Using High-Quality Busbar Covers

The benefits of incorporating electrical busbar covers into your system design go far beyond simple insulation. They include:

- Enhanced electrical safety by reducing risk of accidental contact and arc faults

- Improved system reliability, thanks to added protection against contaminants

- Extended equipment lifespan due to thermal and mechanical shielding

- Compliance with global standards, which can ease inspections and certifications

In essence, investing in quality busbar covers is a preventive measure that mitigates risk and supports long-term performance and uptime.

Customization and Installation Considerations

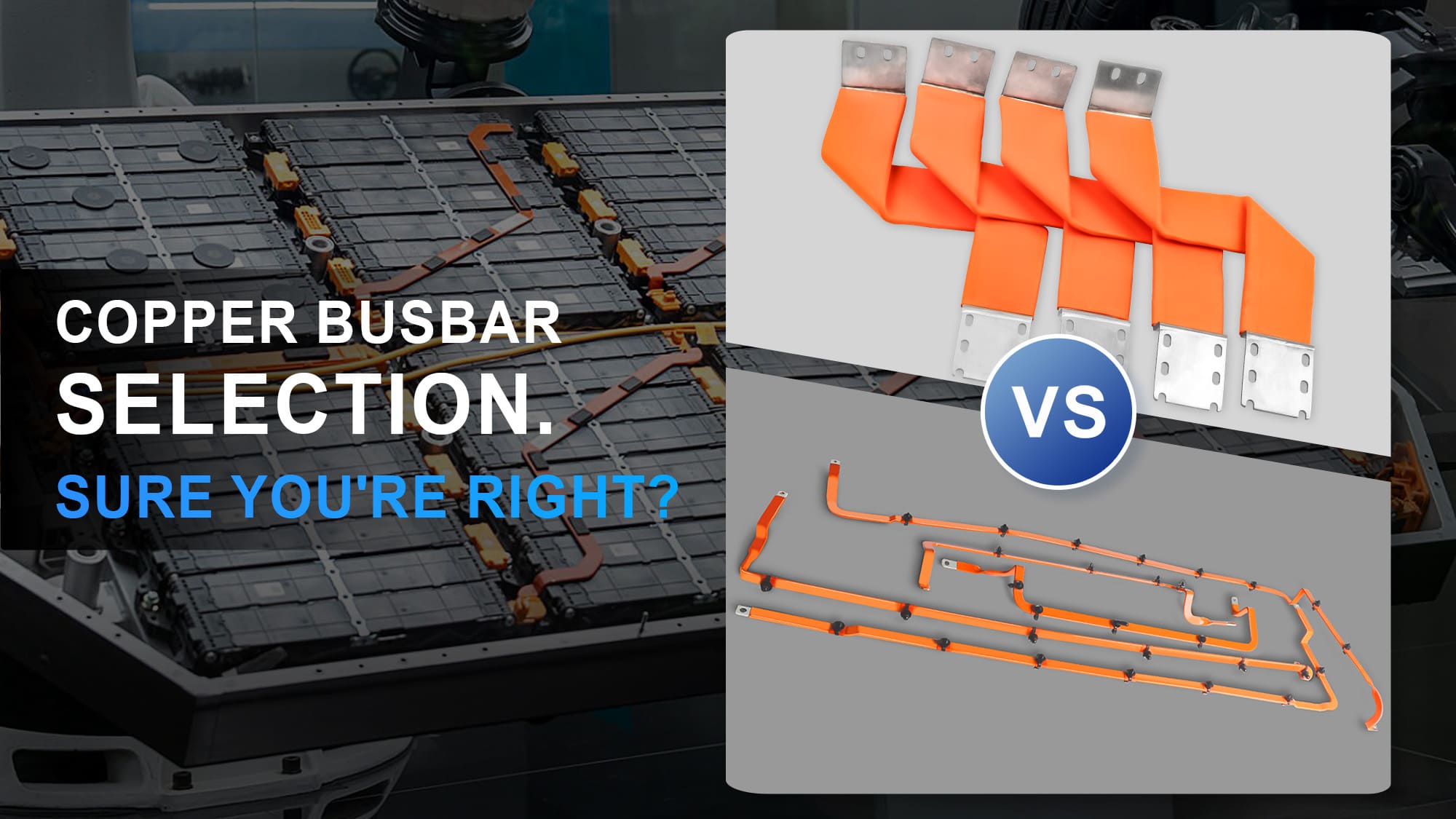

Not all busbar covers are created equal. For optimal performance, it’s important to select covers that match the exact size and shape of your busbar system. Custom-molded busbar insulation covers are available to accommodate complex configurations, bends, or multi-phase layouts.

Some high-end covers also feature transparent insulation to allow visual inspection without the need for disassembly. Others come in color-coded variants for easier phase identification and maintenance.

During installation, care must be taken to ensure tight fitting and full coverage. Gaps or misalignment can render the cover ineffective and compromise electrical safety. Many modern systems also use snap-on or clip-fit designs to streamline installation without additional fasteners or adhesives.

Environmental and Fire Safety Aspects

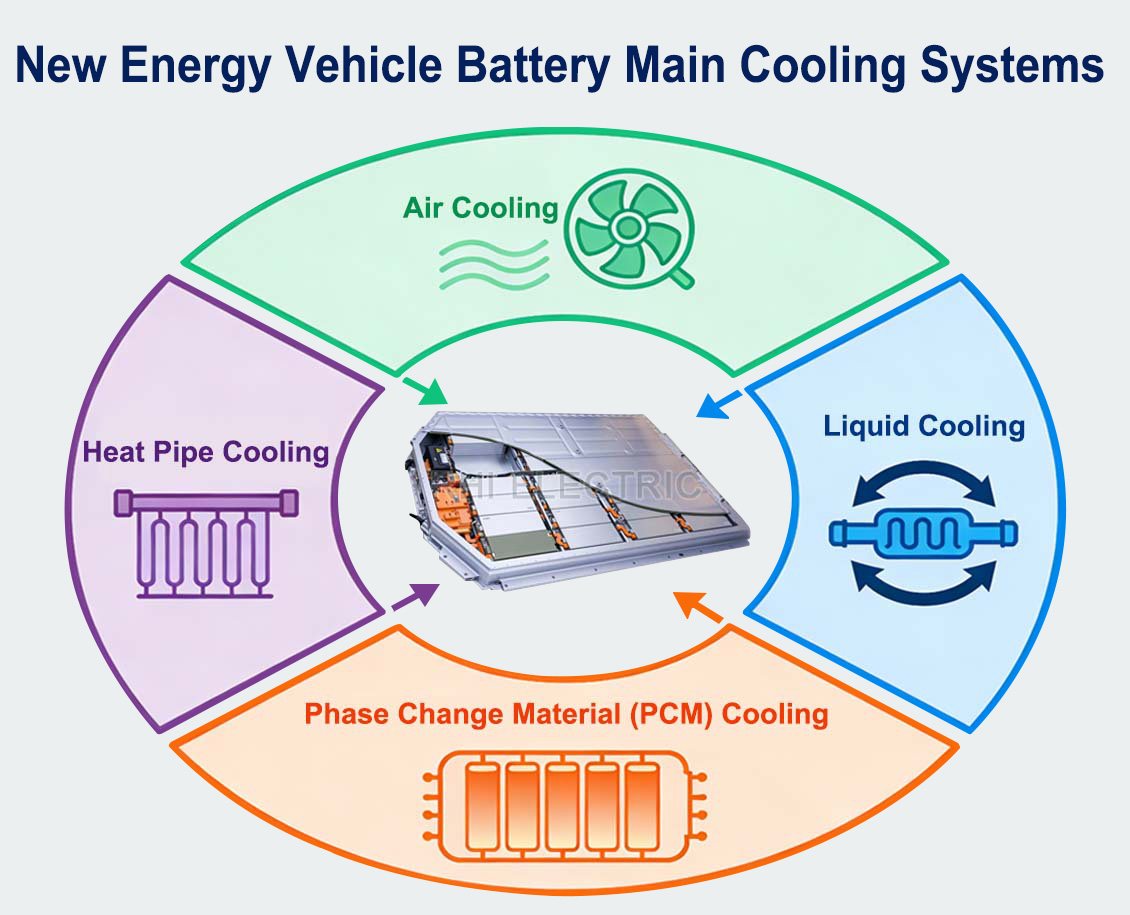

In environments prone to temperature fluctuations, humidity, or chemical exposure, busbar covers provide a first line of defense. Certain models are designed specifically for outdoor use, featuring weather-resistant seals and anti-corrosion coatings.

In fire-sensitive environments like data centers or tunnels, using busbar covers made of halogen-free, low-smoke materials can significantly reduce toxic emissions and enhance evacuation safety during an emergency.

Fire-resistant insulation not only adds another layer of protection but also helps compartmentalize faults, preventing a single incident from cascading into a full-blown system failure.

Conclusion: Smart Protection for a Smart Power Future

As electrical systems become more complex and compact, the need for safe, efficient, and maintainable power distribution is greater than ever. Electrical busbars are foundational components in this evolution, and electrical busbar covers are their essential companions.

By understanding both the definition and function of busbars and their protective elements, professionals can design safer, more efficient, and more sustainable power infrastructure. Whether you are an OEM, MEP contractor, or plant manager, integrating proper busbar protection today can prevent major issues tomorrow.