Understanding Electrical Busbar Material and RHI Electric’s Expertise in Reliable Busbar Solutions

Introduction: The Importance of Busbar Material in Electrical Systems

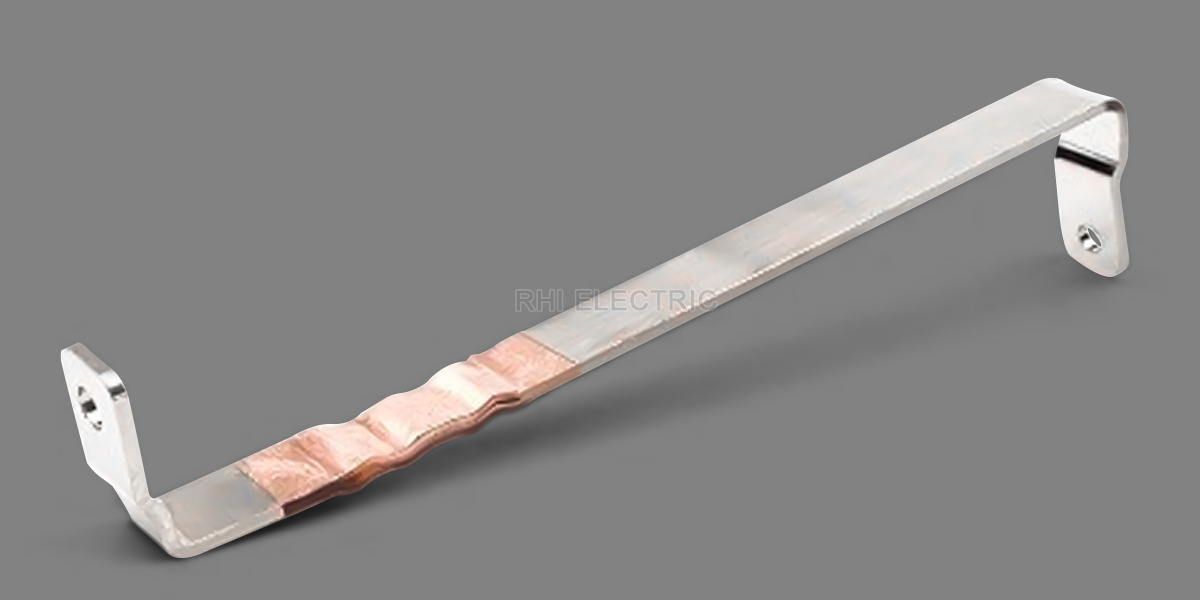

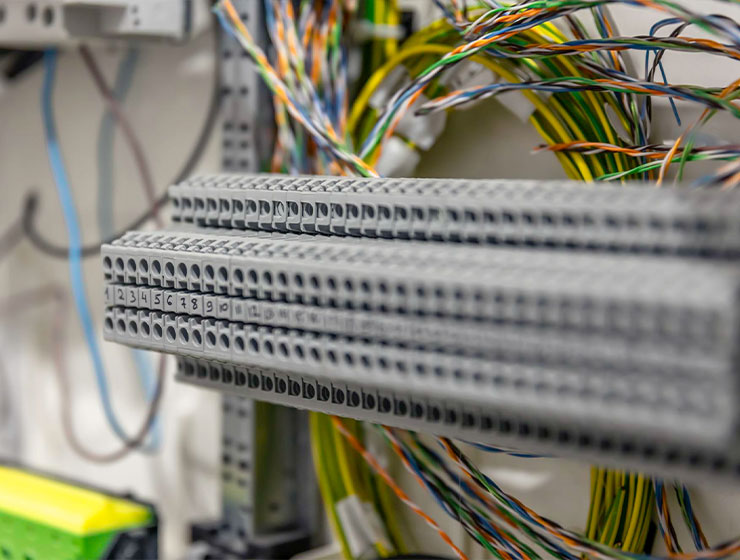

The choice of electrical busbar material significantly impacts the efficiency, safety, and longevity of electrical distribution systems. Busbars are essential for conducting substantial current in switchgear, distribution boards, and industrial power setups, requiring materials that offer low resistance, high conductivity, and excellent mechanical strength. At RHI Electric, we specialize in providing advanced busbar solutions using premium materials, ensuring the stability and reliability of your electrical systems under demanding operational conditions.

Types of Materials Used in Electrical Busbars

Copper and aluminum are the two primary materials used for busbar manufacturing. Copper busbars offer superior conductivity, lower electrical resistance, and higher mechanical strength, making them ideal for critical power distribution systems. Aluminum busbars, while lighter and more cost-effective, provide a practical solution for applications where weight and budget are significant considerations. At RHI Electric, we offer both copper and aluminum busbars, precisely processed to meet different project needs while adhering to international standards.

Why Material Choice Matters for Busbars

Selecting the right busbar material affects not only conductivity but also the durability and thermal management of electrical systems. Copper busbars can handle higher current densities and generate less heat, reducing energy losses and enhancing system efficiency. Aluminum busbars, on the other hand, offer excellent corrosion resistance and are easier to install due to their lighter weight. RHI Electric provides comprehensive guidance to help clients select the optimal material for their busbar systems, ensuring cost-effectiveness without compromising performance.

RHI Electric’s Expertise in Busbar Production

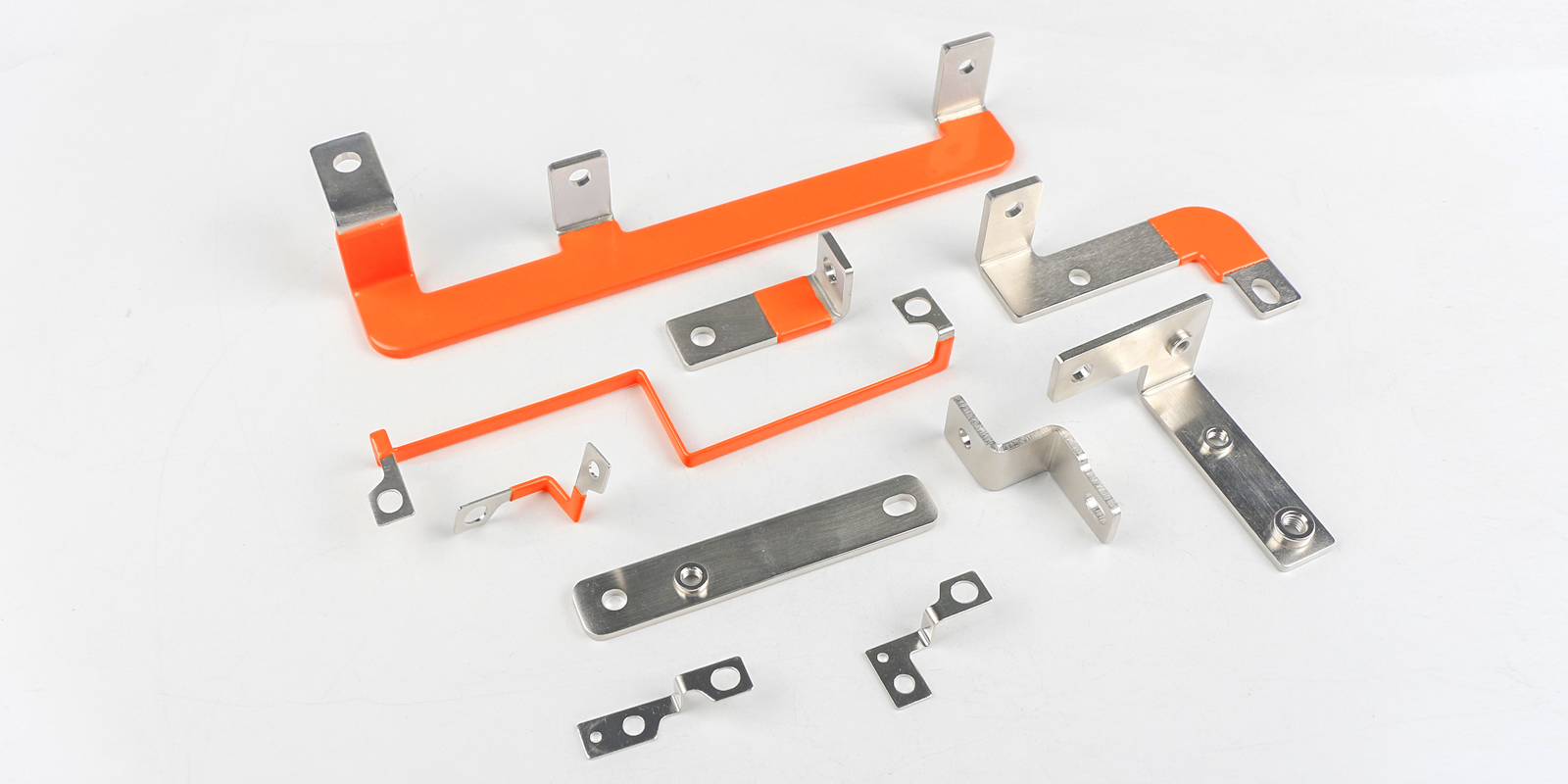

With years of industry experience, RHI Electric has developed advanced manufacturing processes for producing high-quality busbars. Our facilities utilize precise extrusion and machining technologies to maintain dimensional accuracy and surface quality. We also offer custom finishes, including tin plating and insulation coatings, to enhance the corrosion resistance and insulation properties of our busbars, extending their operational lifespan in challenging environments.

Applications of Busbars Using Quality Materials

Busbars manufactured from high-quality materials are used in a wide range of applications:

-

Power distribution panels and switchgear systems in industrial plants.

-

Renewable energy installations, including solar PV and wind energy systems.

-

Electric vehicle charging infrastructure requiring stable high-current transmission.

-

Data centers demanding reliable, low-loss power distribution systems.

RHI Electric’s busbars are engineered to deliver stable performance across these applications, ensuring consistent power distribution and minimizing downtime.

Sustainability and Innovation in Busbar Material Selection

At RHI Electric, sustainability is integral to our production process. We source materials responsibly and implement efficient manufacturing practices to minimize waste while ensuring product quality. Our R&D team continually explores advanced alloys and insulation technologies to improve the performance and sustainability of our busbars, aligning with the evolving needs of the electrical industry.

FAQ: Electrical Busbar Material

Q1: What materials are commonly used for electrical busbars?

Copper and aluminum are the most commonly used materials due to their excellent conductivity and mechanical properties.

Q2: What are the advantages of copper busbars?

Copper busbars offer superior conductivity, lower resistance, and better mechanical strength, making them ideal for high-current applications.

Q3: When should aluminum busbars be used?

Aluminum busbars are suitable for applications requiring lighter weight and lower material costs while still providing good conductivity.

Q4: Does RHI Electric provide custom busbar sizes and finishes?

Yes, RHI Electric offers custom busbar manufacturing with various finishes, including tin plating and insulation coatings.

Q5: Are RHI Electric’s busbars compliant with international standards?

Yes, all RHI Electric busbars are manufactured to meet or exceed global quality and safety standards.