How RHI Electric Defines and Delivers Advanced Busbar Electrical Systems

Discover how RHI Electric designs and delivers advanced busbar electrical systems with precision, reliability, and innovation for modern power solutions.

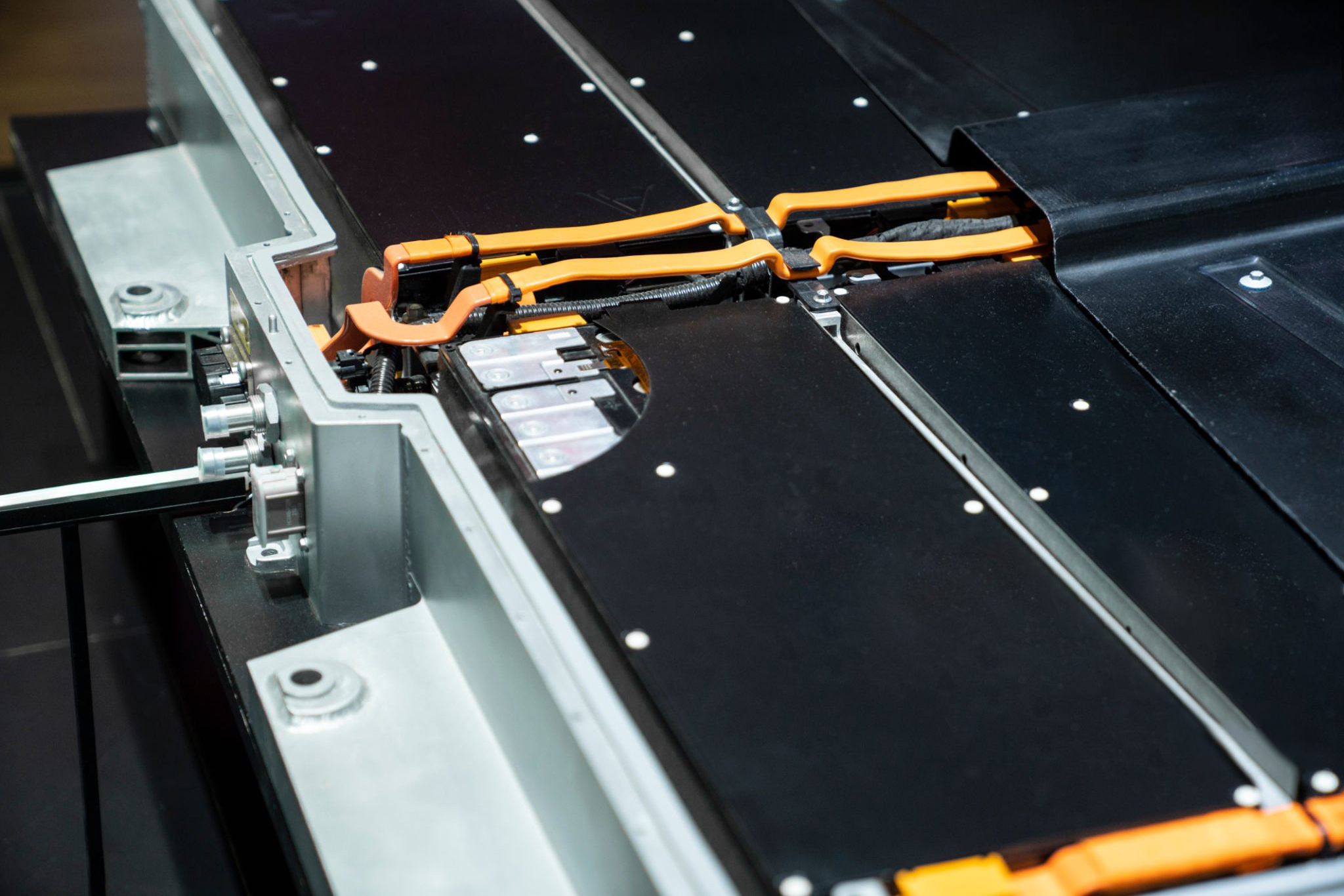

Understanding the Busbar: Definition and Purpose

A busbar is a robust conductor—typically copper, aluminium, or a composite—used to efficiently distribute high currents in switchgear, EV packs, energy storage systems, and industrial control panels. Unlike traditional cable wiring, busbars allow power branching at multiple points, reduce wiring complexity, and offer superior heat dissipation, making them essential in today’s high-performance electrical environments.

RHI Electric treats its busbars as engineered systems, not just metal strips. Their product range spans rigid copper, flexible copper, aluminium, and copper–aluminium composite busbars, including injection-moulded designs optimized for new energy applications. They focus on conductivity, thermal performance, mechanical resilience, and compliance with international standards (IATF 16949, ISO 14001/45001, RoHS, REACH) . This holistic approach ensures busbars meet specific electrical and mechanical demands while fitting neatly into compact layouts.

Materials and Design Excellence

From high-purity 1350 aluminium known for lightweight and corrosion resistance, to flexible-rigid copper composites that simplify routing in EV battery modules, RHI covers the full spectrum of busbar solutions. Customised copper–aluminium busbars offer the conductivity of copper at critical junctions while leveraging aluminium to reduce weight and cost—ideal for electric vehicle and renewable energy applications . Each design balances thermal dissipation, current capacity, and physical integration within constrained spaces.

Intelligent Manufacturing and Quality Control

On a 30,000 m² facility in Wenzhou, RHI employs automated bending, stamping, welding, injection moulding, and CCD visual inspections. Every project goes through DFM review, APQP/PPAP testing, and electrical/mechanical testing, including short‑circuit, pull‑off, and aging assessments. Such rigor, combined with UL/NEMA-grade coating options, ensures not just compliance but performance durability over time.

Real-World Applications Across Industries

Industry |

Application Scenario | Benefits of Using RHI Busbars |

|---|---|---|

| Electric Vehicles (EV) | Battery-to-battery interconnects, BMS, power modules | Lightweight composite materials, high conductivity, compact design |

| Energy Storage Systems (ESS) | Power routing in battery cabinets and rack assemblies | Modular designs, reliable insulation, and thermal stability |

| EV Charging Infrastructure | DC fast-charging piles and AC chargers | High current capacity, corrosion resistance, and rapid installation |

| UPS & Data Centers | Power distribution inside UPS units and switchboards | Customized layouts, low resistance, excellent heat dissipation |

| Industrial Automation | Motor control centers, robotics, and large-scale machinery | Simplifies wiring, reduces faults, enables quick maintenance |

| Renewable Energy (Solar/Wind) | Inverters and power conditioning units | Composite busbars with UV-resistant coatings and anti-corrosion features |

| Rail & Transportation Systems | Onboard electrical systems, control units | Vibration-resistant insulation, high durability in harsh environments |

| Commercial HVAC & Power Panels | Distribution boards for commercial and smart buildings | Clean aesthetics, space-saving integration, and better airflow design |

Advantages That Set RHI Apart

Beyond basic conductivity, RHI’s busbar designs offer improved space utilization, thermal stability, lightweight structure, and rapid assembly. Their composite options reduce material usage, and injection-moulded busbars accelerate manufacturing throughput. Optional insulation coatings—such as epoxy, tin or nickel plating—add mechanical and environmental protection, especially useful in high-vibration or corrosive environments .

FAQ

Q1: What's the difference between copper, aluminium and composite busbars ?

Copper offers maximum conductivity, aluminium is lighter and cheaper, while composite designs combine both, giving you conductivity, weight savings, and cost-efficiency.

Q2: Are busbar systems suitable for EV battery applications?

Absolutely—RHI provides insulated flexible-rigid and injection moulded busbars specifically designed for EV battery packs, offering safe, efficient, and space-optimized connections.

Q3: How does RHI Electric assure busbar quality?

They follow strict DFM reviews, use APQP/PPAP protocols, maintain IATF 16949 and ISO certifications, and perform full electrical and mechanical testing, ensuring high reliability.

Q4: What defines a 'busbar electrical system?

It is an integrated setup where busbars, holders, adapters, and protective covers form a modular and efficient power distribution framework—simplifying wiring, enhancing safety, and enabling scalable power delivery.