What Is a Rigid Copper Busbar? Applications, Advantages & Industry Uses

Explore everything you need to know about rigid copper busbars, including their structure, benefits, applications, design considerations, and why they remain a preferred choice for electrical engineers and manufacturers worldwide.

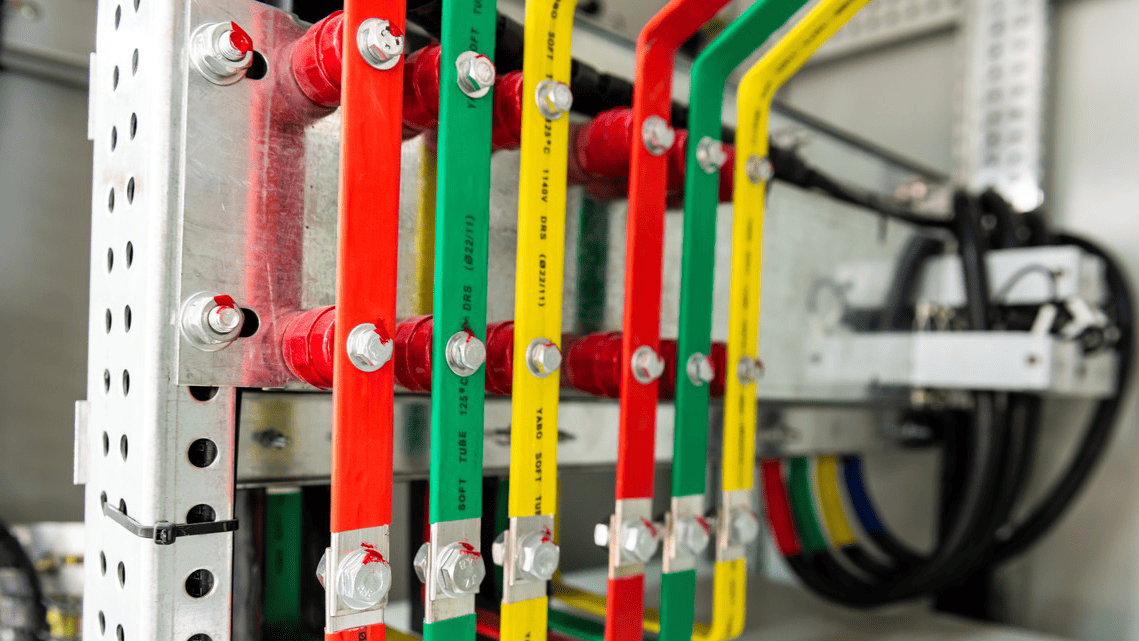

In today’s power distribution and electrical infrastructure, reliability, efficiency, and conductivity are key. One component that has consistently proven its worth in these areas is the Rigid Copper Busbar. Whether in power substations, switchgear systems, industrial panels, or renewable energy setups, rigid copper busbars play a foundational role in modern electrical systems.

This comprehensive guide will explore everything you need to know about rigid copper busbars, including their structure, benefits, applications, design considerations, and why they remain a preferred choice for electrical engineers and manufacturers worldwide.

What is a Rigid Copper Busbar?

A rigid copper busbar is a flat or shaped bar made of copper used for conducting electricity within electrical panels, switchgear, or other electrical apparatus. Unlike flexible busbars or cable-based solutions, a rigid copper busbar maintains a fixed, solid shape, which allows for easier current control, improved durability, and better heat dissipation.

These busbars are typically made from high-conductivity copper with a purity of 99.9%, ensuring optimal electrical performance. Depending on the requirement, rigid copper busbars can be coated (e.g., with tin, silver, or nickel) to improve corrosion resistance and conductivity.

Why Use Rigid Copper Busbars?

1. Superior Electrical Conductivity

Copper is known for its excellent electrical conductivity—second only to silver. A rigid copper busbar offers minimal electrical resistance, which helps in reducing power losses during transmission and distribution.

2. Mechanical Strength

The rigidity of copper busbars makes them ideal for applications that require a solid, durable current-carrying component. They can handle mechanical stresses and support heavy-duty connections, especially in high-current environments.

3. Thermal Efficiency

Copper has a high thermal conductivity, making rigid copper busbars excellent at managing heat buildup. This minimizes the risk of overheating and extends the lifespan of electrical components.

4. Ease of Installation

Pre-formed, rigid copper busbars simplify the installation process. With precise dimensions and bend angles, they eliminate the guesswork and inconsistency that comes with cable-based wiring.

5. Customizable and Scalable

Manufacturers can tailor rigid copper busbars to meet exact design specifications, including thickness, width, insulation, and surface coating. This makes them suitable for applications ranging from compact control panels to massive industrial switchboards.

Key Applications of Rigid Copper Busbars

1. Electrical Panels and Switchboards

Rigid copper busbars are the backbone of most electrical control systems. They distribute power across breakers, relays, and terminals in a compact and organized manner.

2. Power Substations

In medium and high-voltage substations, rigid copper busbars are used to interconnect transformers, breakers, and other switchgear. Their stability and high current capacity make them ideal for such demanding environments.

3. Renewable Energy Installations

Solar and wind energy systems benefit from the high conductivity and low maintenance requirements of rigid copper busbars. They are often used in inverter stations and energy storage setups.

4. Industrial Automation

Manufacturing facilities use rigid copper busbars in motor control centers (MCCs) and programmable logic controller (PLC) cabinets for efficient power distribution.

Design Considerations for Rigid Copper Busbars

Designing a rigid copper busbar system involves several critical parameters:

1. Current Carrying Capacity

The cross-sectional area of the busbar must support the maximum current load without exceeding permissible temperature limits. IEC 61439 and UL 891 standards provide guidelines for safe design.

2. Voltage Drop

Minimizing voltage drop is essential, especially in long busbar runs. This is achieved by optimizing the bar’s length, width, and material purity.

3. Short-Circuit Withstand Capacity

Rigid copper busbars must endure high fault currents without deformation or failure. This requires calculations based on the duration and intensity of potential short circuits.

4. Insulation and Coating

Although copper has excellent conductivity, it must be properly insulated or coated to prevent accidental contact and corrosion. Common insulation types include heat-shrink sleeves, epoxy powder coatings, and PVC laminations.

5. Thermal Management

Busbar designs often incorporate air gaps or additional cooling components to manage heat. In high-power setups, forced air or liquid cooling may be used.

Types of Rigid Copper Busbars

1. Flat Copper Busbar

These are the most common type, used in low and medium-voltage applications. They are easy to fabricate and install.

2. Edgewise Copper Busbar

Edgewise-mounted busbars reduce footprint and improve airflow in compact installations.

3. Hollow Copper Busbar

Used where weight reduction and high-current transfer are necessary. The hollow structure also facilitates better cooling.

4. Laminated Rigid Copper Busbar

Composed of multiple layers of copper with insulation between them, this type minimizes inductance and improves performance in high-frequency applications.

Materials and Surface Treatments

The performance of a rigid copper busbar depends greatly on the material and surface finish:

- Electrolytic Tough Pitch Copper (ETP Copper) is commonly used due to its excellent conductivity.

- Silver Plating is ideal for very high-current, low-voltage connections due to its superior conductivity.

- Tin Plating provides corrosion resistance and easier solderability.

- Nickel Plating offers improved resistance to high temperatures and oxidation.

Manufacturing Techniques

Manufacturing rigid copper busbars involves several precision processes:

- Cutting and Punching: CNC machines ensure clean edges and accurate hole placements.

- Bending and Forming: Hydraulic presses and custom dies shape the copper without cracking.

- Deburring and Finishing: This step removes sharp edges and prepares the surface for plating or insulation.

- Coating and Insulation: Based on application needs, coatings are applied for safety and durability.

Conclusion

The rigid copper busbar remains a fundamental component in electrical infrastructure thanks to its unparalleled conductivity, mechanical stability, and customization capabilities. As technology evolves and demand for high-efficiency power distribution grows, the role of rigid copper busbars will only become more critical.

Whether you're designing a data center, setting up a renewable energy plant, or upgrading an industrial power system, investing in a well-designed rigid copper busbar setup is a decision rooted in reliability, safety, and long-term value.

FAQs about Rigid Copper Busbar

Q1: Is a rigid copper busbar better than aluminum?

Yes, copper has better conductivity and mechanical strength, though aluminum is cheaper and lighter. The choice depends on application and cost constraints.

Q2: Can a rigid copper busbar be bent during installation?

It can be bent during manufacturing using precision tools, but field bending is not recommended due to the risk of fractures or improper alignment.

Q3: Are rigid copper busbars fire-resistant?

Copper itself does not burn, and with proper insulation (like epoxy or PVC), busbars can be made highly fire-resistant.

Q4: How long does a rigid copper busbar last?

With proper maintenance and environmental control, a rigid copper busbar can last 30 years or more.

Q5: Is it possible to recycle rigid copper busbars?

Yes, copper is 100% recyclable without degradation of its electrical properties, making rigid copper busbars an environmentally sustainable choice.