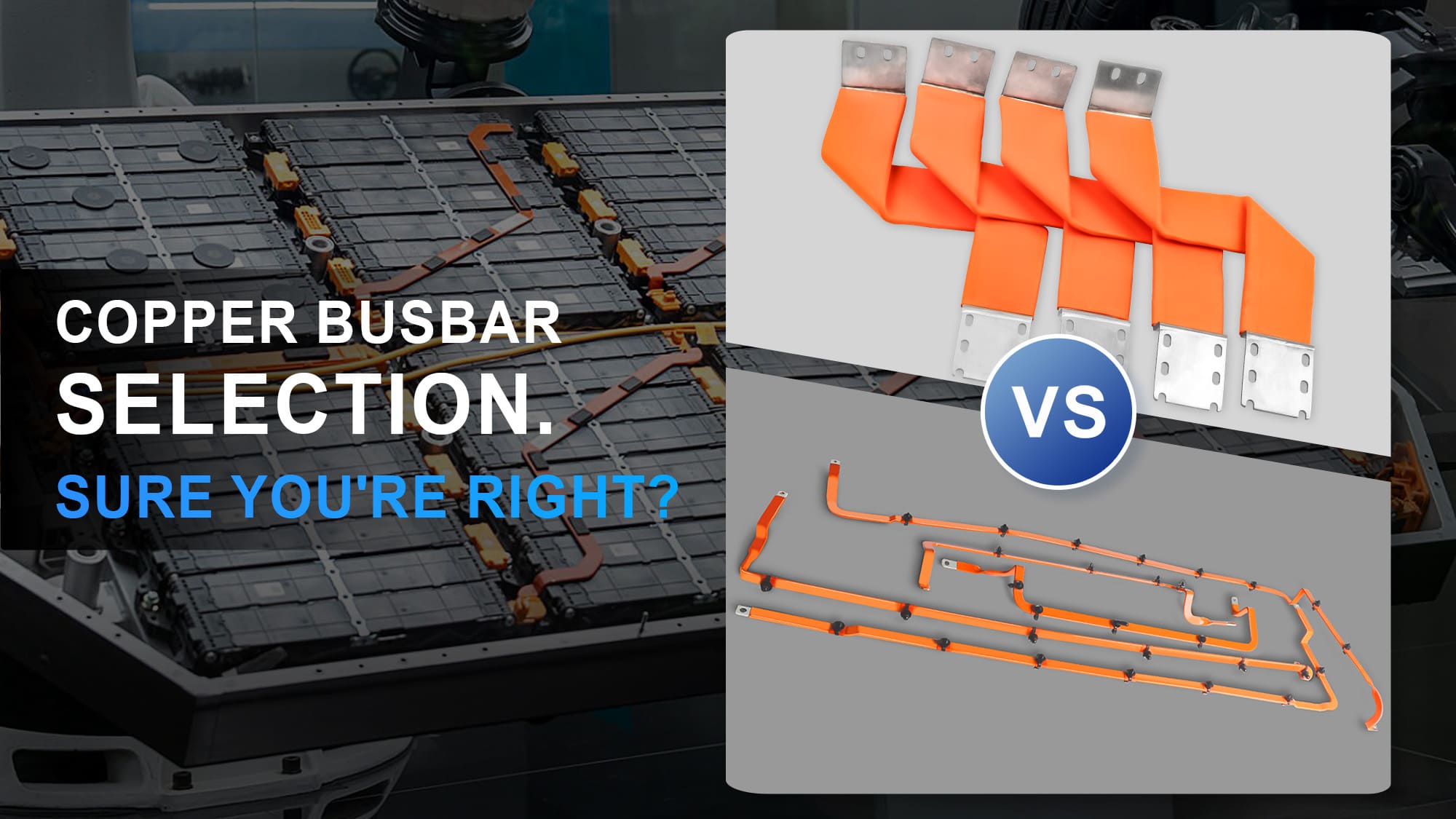

Flexible Aluminium Busbar: The Future of Efficient Electrical Distribution

Explore everything you need to know about Flexible Aluminium Busbars—from their construction and working principles to applications, advantages, and how they compare to conventional busbar systems.

In today’s fast-evolving electrical and energy landscapes, optimizing power distribution has become critical. One innovation revolutionizing the industry is the Flexible Aluminium Busbar—a modern alternative to traditional copper and rigid aluminium conductors. Lightweight, cost-effective, and easy to install, these busbars offer a compelling combination of performance and efficiency.

This in-depth article explores everything you need to know about Flexible Aluminium Busbars—from their construction and working principles to applications, advantages, and how they compare to conventional busbar systems.

What is a Flexible Aluminium Busbar?

A Flexible Aluminium Busbar is a type of electrical conductor designed to efficiently distribute electricity within an electrical system while offering mechanical flexibility. Unlike traditional rigid busbars, which are limited in shape and placement, flexible busbars are engineered to bend, twist, and conform to complex geometries. This makes them ideal for space-constrained applications and systems subject to mechanical vibrations.

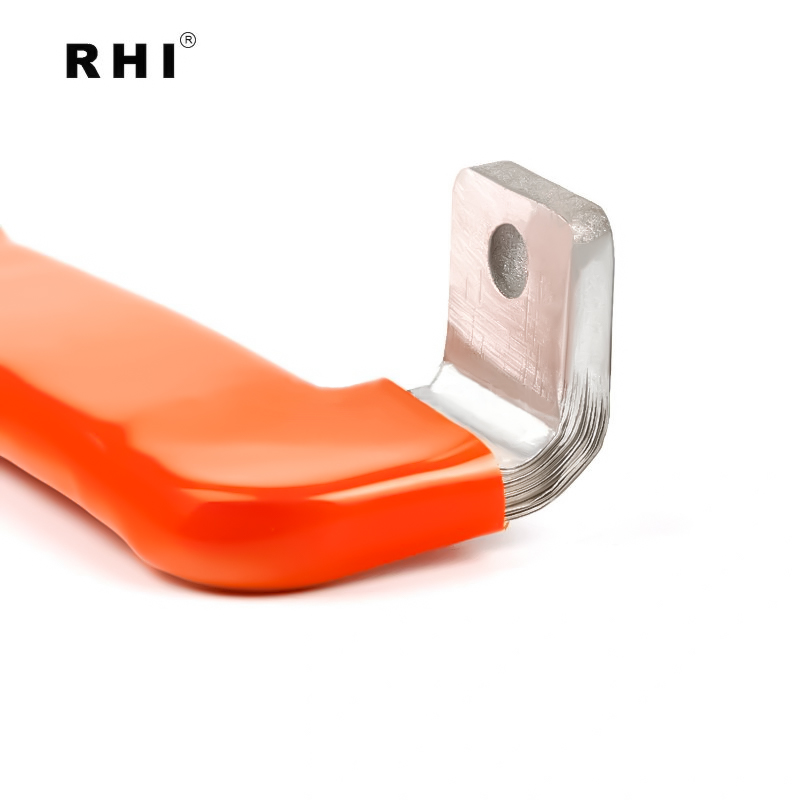

Made from multiple thin layers of aluminium that are laminated together, these busbars are further protected with insulation materials to ensure safe operation. The flexibility provided by this structure allows engineers to design more compact, efficient, and modular power systems without compromising reliability.

Flexible Aluminium Busbars are gaining popularity in various industries including renewable energy, electric vehicles, data centers, and industrial automation due to their adaptability and cost-efficiency.

Key Components and Structure

The performance and reliability of a Flexible Aluminium Busbar depend heavily on its structural components. Here's a breakdown of its main elements:

a. Aluminium Conductive Layers

These are ultra-thin aluminium strips or foils stacked in parallel to increase current-carrying capacity while maintaining flexibility. The use of aluminium helps in weight reduction and cost savings.

b. Insulation Layers

To prevent short circuits and electrical leakage, each conductive layer or the entire stack is insulated using materials such as:

- PVC (Polyvinyl Chloride)

- PET (Polyethylene Terephthalate)

Epoxy Powder Coating These materials are chosen for their thermal resistance, mechanical durability, and flame retardancy.

c. Terminal Ends

Custom-fabricated or punched to suit specific applications, terminal ends enable the connection of the busbar to components like batteries, circuit breakers, or terminals.

d. Outer Protective Layer

Heat shrink tubing or silicone sleeves are often used to provide additional protection against moisture, abrasion, and UV exposure.

How Flexible Aluminium Busbars Work

The working principle of a Flexible Aluminium Busbar is based on efficient electrical conduction through layered aluminium foils. Here's how it functions:

Current Flow

Electric current flows across the laminated aluminium strips, which are designed to handle high current loads with minimal resistance. The layered design allows for a broader conductive path, reducing overall resistance and power loss.

Mechanical Flexibility

The multi-layered construction allows the busbar to flex without cracking, making it ideal for applications requiring movement or complex routing. This is particularly useful in vehicles and compact enclosures.

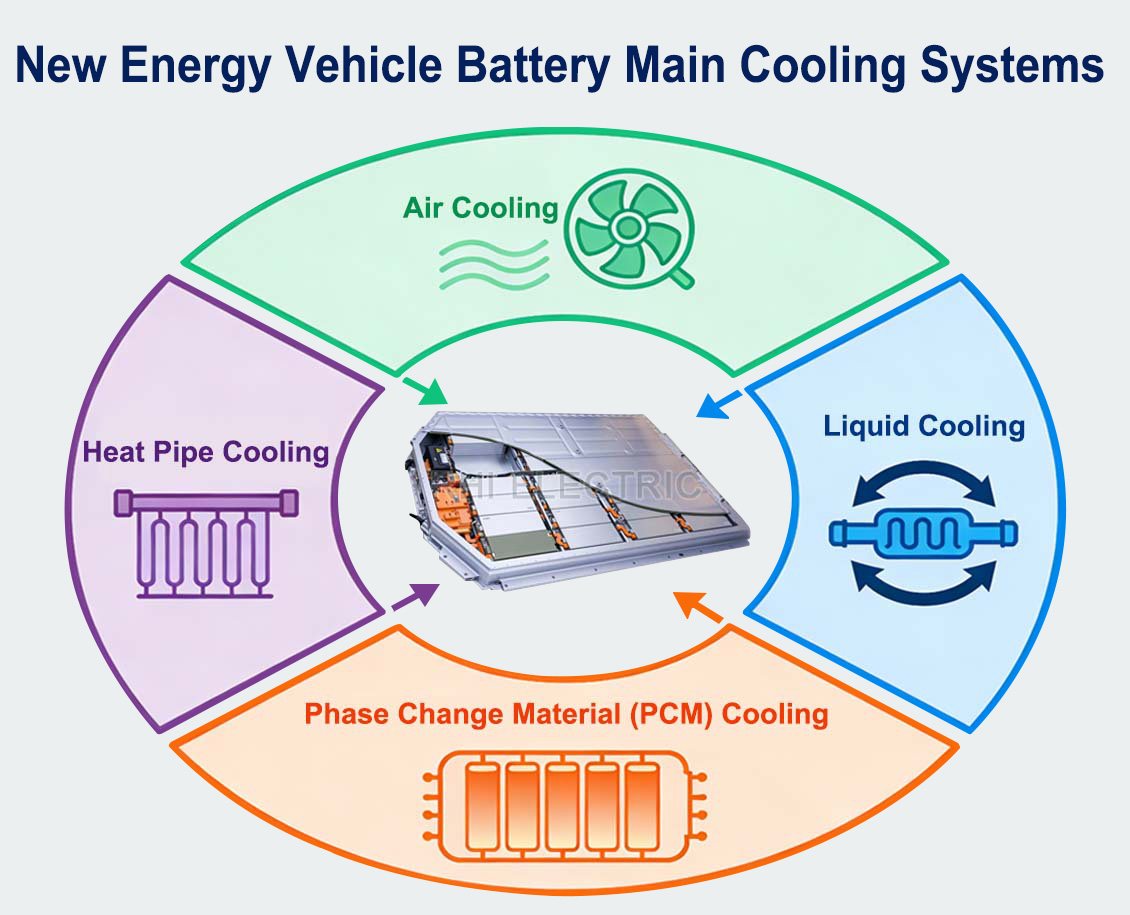

Thermal Management

Flexible Aluminium Busbars provide excellent heat dissipation due to their increased surface area and airflow between laminations. This reduces the need for external cooling systems and increases operational reliability.

Types of Flexible Aluminium Busbars

Depending on the application, different types of flexible aluminium busbars are available:

a. Laminated Flexible Busbars

These consist of stacked aluminium foils insulated and bonded into a flat profile. They offer excellent electrical performance and are commonly used in switchgear and control panels.

b. Braided Aluminium Busbars

Made by braiding aluminium wires, this type offers extreme flexibility and is ideal for applications subject to vibration, such as railways or moving machinery.

c. Solid-Flex Busbars

Composed of aluminium plates joined mechanically or through flexible joints, these provide a balance between flexibility and high current capacity.

d. Custom-Profiled Busbars

Tailor-made for specific layouts in EVs, batteries, or compact enclosures. These may include L-shaped, U-shaped, or spiral designs depending on routing needs.

Benefits of Using Flexible Aluminium Busbars

There are several compelling advantages to using Flexible Aluminium Busbars:

Cost Efficiency

Aluminium is more abundant and cheaper than copper, resulting in significant material cost savings, particularly in large-scale installations.

Lightweight

Aluminium's low density means flexible aluminium busbars are lighter than their copper counterparts. This is beneficial for aerospace, EV, and transport industries where weight savings translate to energy efficiency.

Space-Saving Design

Due to their bendable nature, these busbars can be routed around obstacles and within tight spaces, allowing more compact system designs.

Superior Heat Dissipation

The high surface-to-volume ratio improves cooling, allowing systems to run cooler and more efficiently.

Improved Safety

The use of high-quality insulation and protective layers reduces the risk of electrical hazards such as short circuits and fires.

Ease of Maintenance

Flexible Aluminium Busbars are modular and easier to replace or upgrade compared to rigid copper bars.

Applications in Various Industries

a. Renewable Energy Systems

Used in photovoltaic inverters and battery energy storage systems to manage fluctuating power flows efficiently.

b. Electric Vehicles

Serve as interconnects between batteries, power inverters, and electric motors. Their flexibility supports the compact, high-density layouts required in EVs.

c. Power Distribution Units (PDUs)

Offer efficient and safe power routing in electrical panels, switchboards, and UPS systems.

d. Data Centers

Flexible Aluminium Busbars support dense power distribution architectures, improving cooling and space utilization.

e. Railway and Transport

Provide stable and vibration-resistant electrical connections in locomotives and metro trains.

f. Industrial Automation

Used in robotics, CNC machinery, and industrial controls, where flexibility and space optimization are key.

Installation and Maintenance Guidelines

Installation Best Practices

- Pre-measure Bending Radius: Ensure bends do not exceed the recommended radius to prevent damage.

- Use Proper Torque: Apply the right torque during terminal connection to avoid loosening or damage.

- Ensure Alignment: Misaligned holes can cause mechanical stress and failure.

Maintenance Guidelines

- Visual Inspections: Regularly check for signs of wear, corrosion, or thermal damage.

- Thermal Imaging: Use to detect hot spots and prevent overheating.

- Insulation Testing: Perform periodic insulation resistance tests to ensure continued safety.

Environmental and Economic Considerations

Environmental Benefits

- Lower Emissions: Aluminium production (from recycled materials) emits fewer greenhouse gases than copper.

- Recyclability: Aluminium busbars can be recycled without loss of properties.

- Energy Efficiency: Better thermal management reduces energy consumption in cooling systems.

Economic Factors

- Reduced Operating Costs: Lower material costs and easier maintenance reduce total cost of ownership.

- Transportation Savings: Lower weight means reduced freight costs.

- Increased ROI: Longer lifespan and modular design improve return on investment.

Conclusion

As the world moves toward smarter, more efficient energy systems, the Flexible Aluminium Busbar is proving to be a cornerstone of modern power distribution. With its lightweight structure, flexibility, and cost-effectiveness, it addresses the limitations of traditional rigid conductors.

From electric vehicles and renewable energy to industrial automation and data centers, the Flexible Aluminium Busbar is helping engineers rethink how they distribute and manage electrical power. As technology continues to evolve, expect its role to grow even more pivotal in the energy transition era.

Whether you’re an electrical engineer, system integrator, or facility manager, understanding and adopting Flexible Aluminium Busbar solutions could significantly enhance the performance, reliability, and sustainability of your power infrastructure.