Aluminium Busbar Flexible Battery Bus Bar

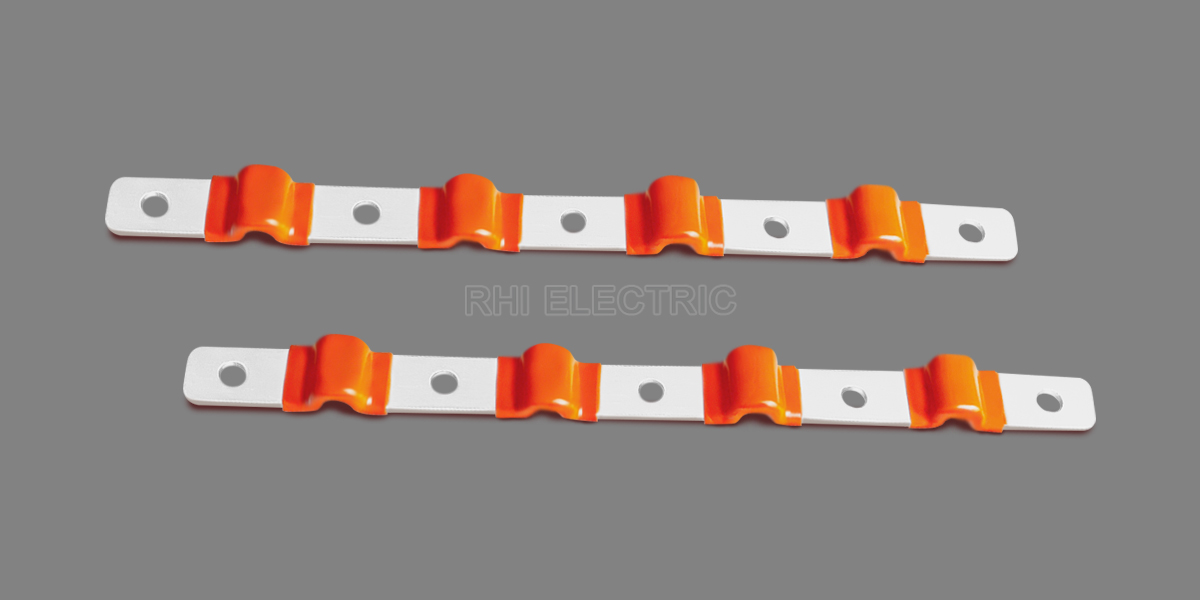

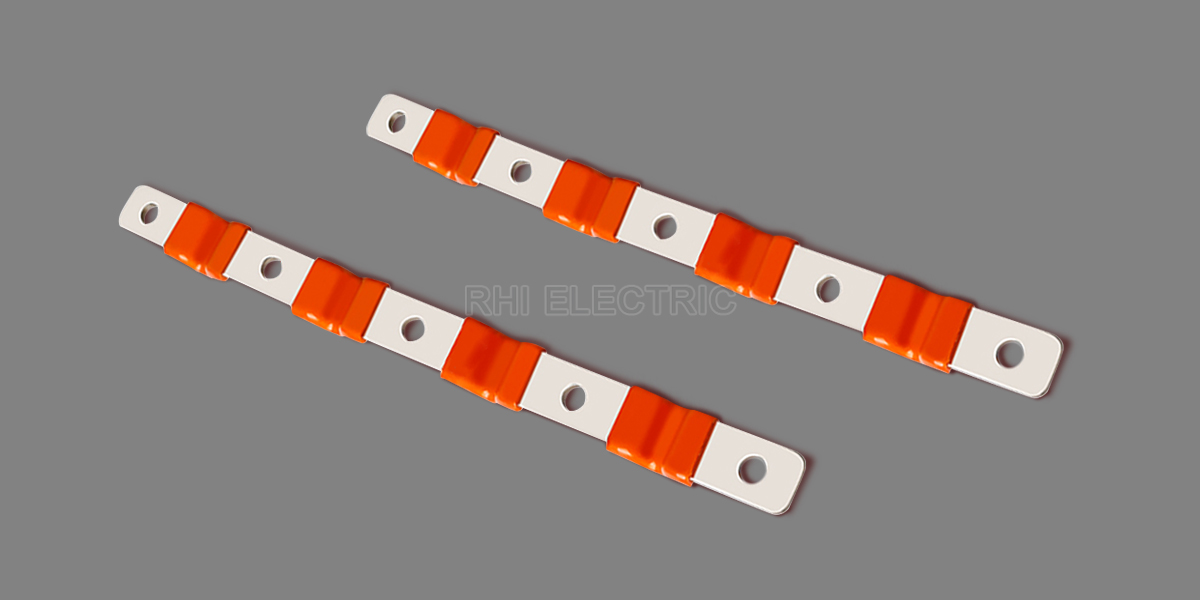

In compact EV battery packs, flexible busbars provide multi-axis bending to compensate for length tolerances and simplify assembly. A laminated aluminium-foil structure minimizes skin effect, enabling 200–800 A current capacity with improved heat dissipation. Nickel-clad outer layers enhance the aluminium busbar's machinability and wear resistance, while local PVC dip-coated insulation provides a –40 °C to 105 °C temperature rating, ≥3 kV dielectric strength, and high flame retardancy.

In space-constrained new-energy applications, flexible busbars are widely used for their excellent multi-axis bending capability. By absorbing length tolerances through controlled flexing, they provide built-in assembly compliance and greatly simplify installation.

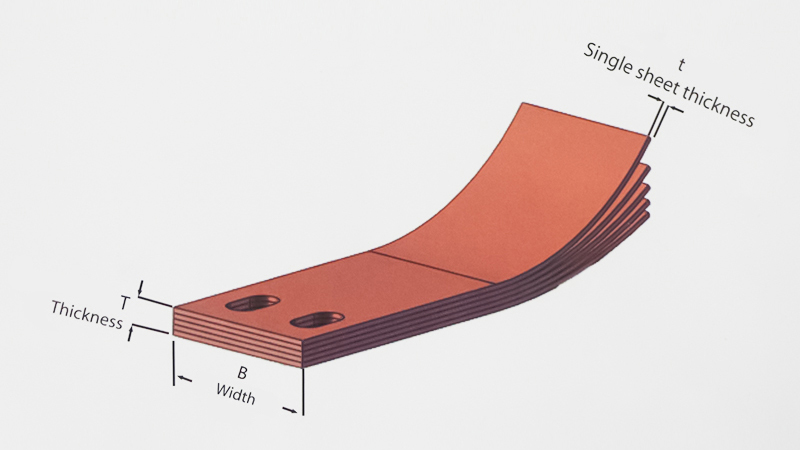

To carry 200–800 A AC, the conductor is typically formed from 10–50 layers of 0.2 mm 1060 aluminium foil. This laminated thin-layer design reduces skin-effect losses while improving current density and heat dissipation.

Nickel-clad outer layers enhance machinability, weldability, and wear resistance. For insulation, critical areas are PVC dip-coated, delivering a –40 °C to 105 °C temperature rating, ≥3 kV dielectric strength, and the highest flame-retardant class.

Insulation Protection

Local PVC dip-coated insulation provides the following performance:

-

Temperature range: –45 °C to 105 °C

-

Dielectric withstand voltage: 4000 V DC, 1 min

-

Flame rating: Highest class (e.g., UL94 V-0)

|

Material |

Single Sheet Thickness(t) |

Width(B) |

Thickness(T) |

||||||||

|

Al strip |

0.2 |

18 |

22 |

28 |

30 |

35 |

40 |

45 |

48 |

60 |

1~10 |

Electrical Performance Requirements

1. Aluminium foil conductivity

Based on 1060 aluminium and manufacturing effects:

-

For foil thickness ≤ 1.5 mm: ≥ 59% IACS (≈ 34.1 MS/m)

-

For foil thickness > 1.5 mm: ≥ 57% IACS (≈ 32.9 MS/m)

2. Rated current verification

At 25 °C ambient temperature, under continuous rated current (200–800 A), the flexible busbar shall meet:

-

No visual damage, plating loss, or burn marks

-

Temperature rise ≤ 40 K (per GB/T 15576)

-

Insulation resistance ≥ 100 MΩ at 500 V DC, meeting high-voltage component insulation requirements

Application Advantages

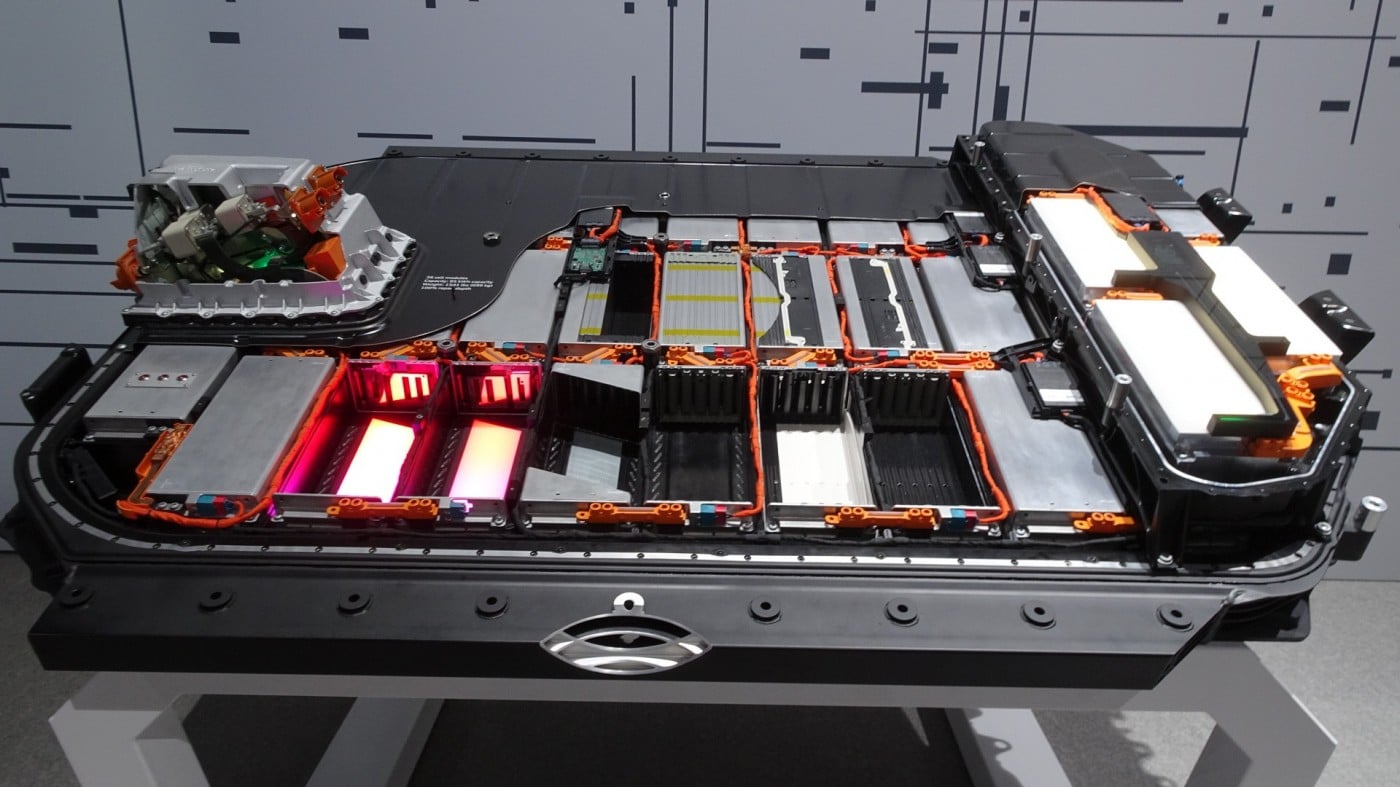

EV Battery Packs

Designed for high-density battery layouts, the flexible multi-axis bending capability enables installation in tight spaces while compensating for manufacturing and assembly tolerances, significantly improving high-voltage system integration and vehicle-level compatibility.

Energy Storage Systems (ESS)

The laminated thin-aluminium-foil structure reduces AC skin-effect losses, increases effective current-carrying area, and improves heat dissipation. It supports stable 200–800 A operation for both DC and AC power transfer in energy storage systems.

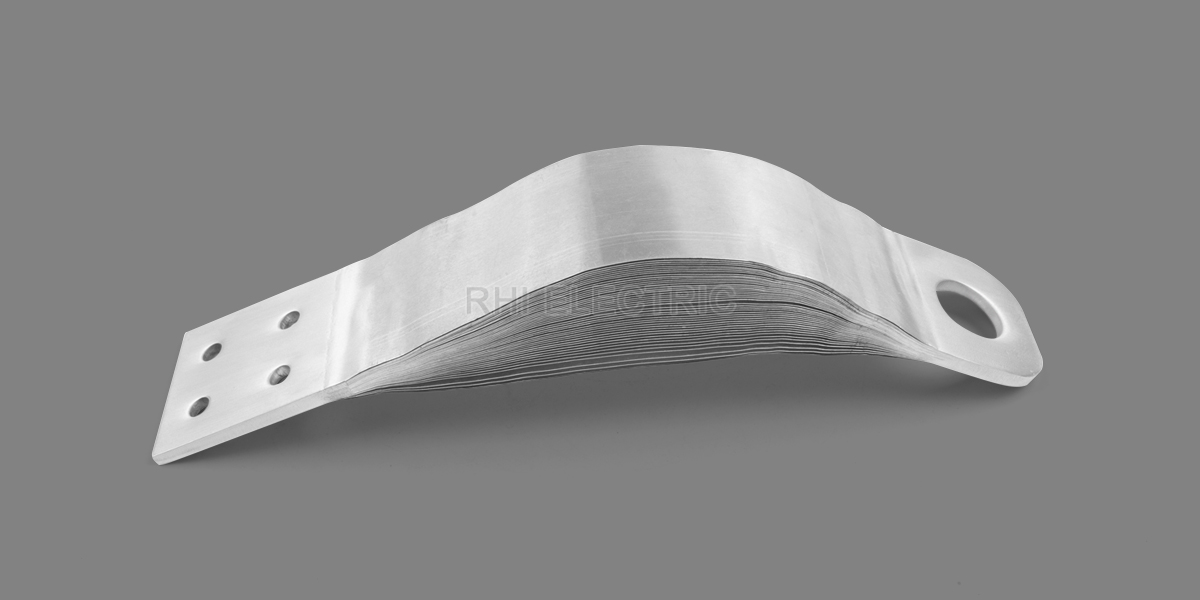

HV/LV Power Distribution

In HV/LV distribution systems, the flexible busbar uses an arched design to absorb thermal expansion and prevent stress-related failures. The laminated aluminium foils are welded at the terminals, with nickel sheets on both surfaces to improve corrosion resistance, wear resistance, and electrical contact stability, ensuring reliable operation in humid and salt-spray environments.