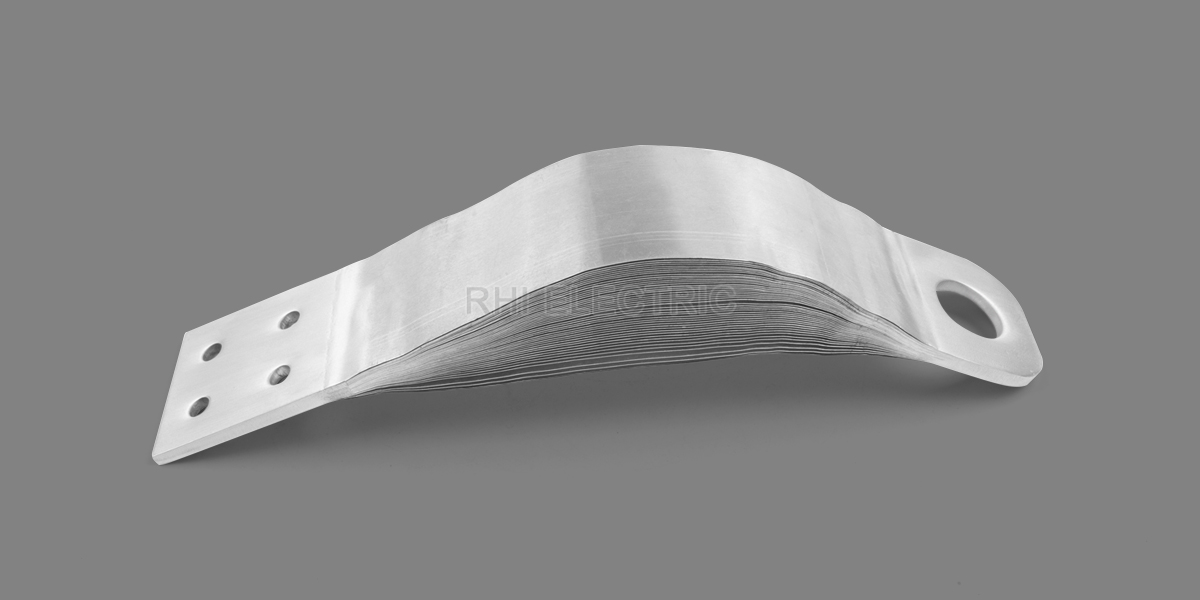

Aluminium Busbar Flexible Battery Bus Bar for EV Powertrain

Flexible busbar features laminated aluminium layers with diffusion-bonded terminals, delivering stable low resistance and strong mechanical integrity. The aluminium busbar offers high electrical and thermal efficiency, withstand vibration, and flex to accommodate thermal expansion. Protected by heat-shrink insulation, these busbars enable compact layouts and ensure long-term, reliable power distribution in EV battery packs, energy storage systems, and other demanding new energy applications.

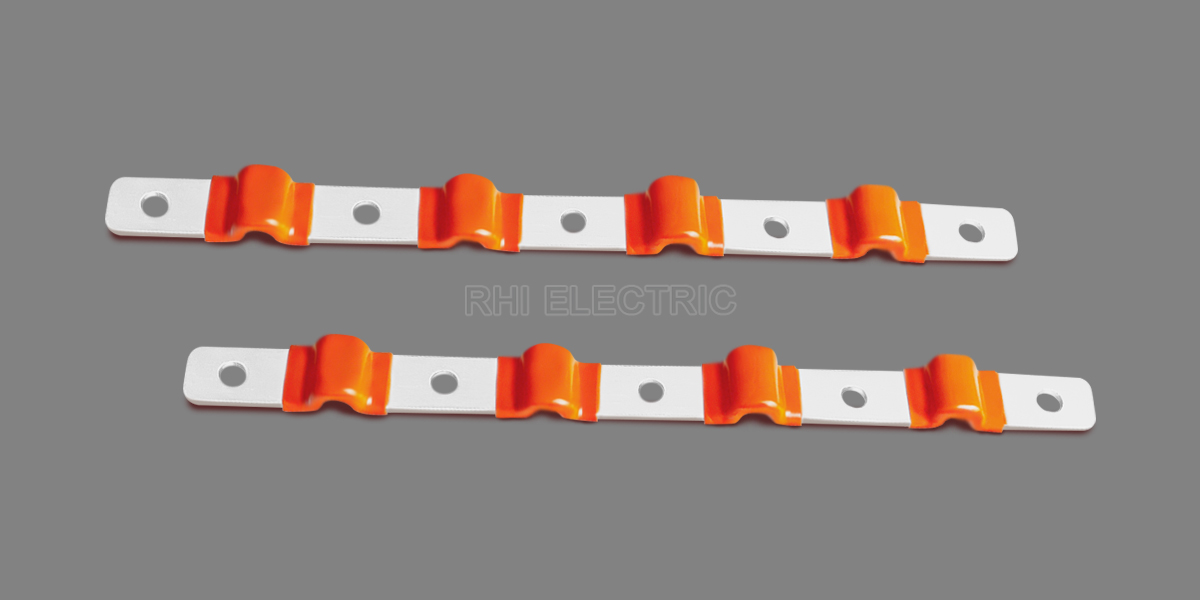

The flexible busbar is built around a conductive core formed from 0.2 mm aluminium strips and insulated with a tightly shrunk PE/EVA heat-shrink sleeve with a wall thickness of 1.0–1.5 mm. This insulation design is aligned with manufacturing specifications for new energy electrical interconnection components, ensuring a high level of safety and long-term reliability, as outlined below:

- Flame Retardancy Performance: The PE/EVA heat-shrink sleeve achieves a UL 94 V-0 flame-retardant rating, satisfying fire protection requirements for EV battery systems and electrical control units by effectively limiting flame propagation under short-circuit conditions.

- Insulation Performance: With a 1.0–1.5 mm PE/EVA insulation layer, the busbar delivers stable electrical insulation, providing ≥100 MΩ insulation resistance at 1000 VDC and withstanding 2500 VAC for 5 minutes under standard test conditions (25 °C, 50% RH). Its theoretical dielectric strength of 18–37.5 kVAC offers sufficient safety margin for sustained operation in high-demand new energy and electrical applications.

- Structural Advantages: The heat-shrink sleeve conforms closely to the surface of the flexible busbar, creating an effective barrier against moisture, dust, and other contaminants, thereby reducing creepage paths and short-circuit risk. The 0.2 mm aluminium strip conductor ensures high electrical conductivity while preserving flexibility, enabling convenient installation in compact new energy system layouts.

- Application Scope: This flexible aluminium busbar is engineered for high-reliability new energy interconnection applications, including battery module connections, internal wiring of power control units (PCUs), and current transmission components within energy storage systems (ESS).

| Parameter | Withstand Voltage | RoHS | Flammability Rating | Working Temperature | Wall Thickness | Conductor Material |

| Values | 4000 V DC, 1 min | Qualified | UL94 V-0 | -50~125°C | 1.0-1.5mm | T2 Copper/Aluminium |

RHI Manufacturing Strength

RHI holds multiple internationally recognized certifications, including RoHS, REACH, UL94 V-0, ISO 14001, ISO 45001, and IATF 16949. With over a decade of experience in new energy busbar manufacturing, RHI is a trusted Tier 1 supplier to both domestic and global markets. Our customers include CATL in power battery systems, the Renault–Nissan Alliance in automotive applications, and Trinasolar in energy storage. RHI is also a global partner of XPENG Motors, while BYD has completed supplier audits and approved RHI as a qualified supplier—underscoring our technical strength, consistent quality, and long-term partnership capability.