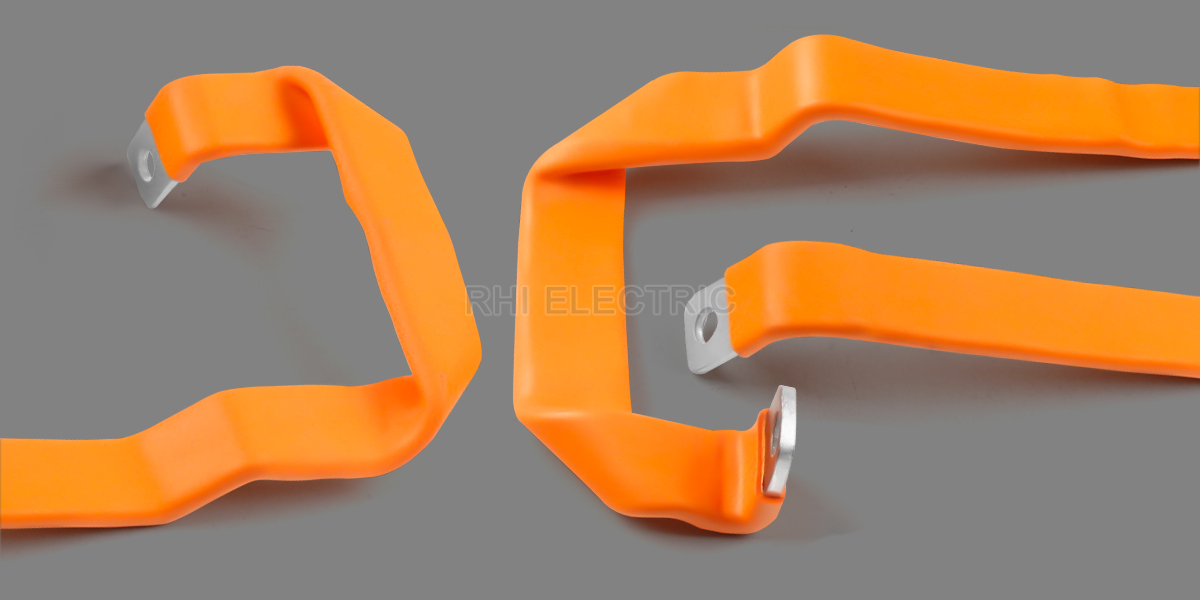

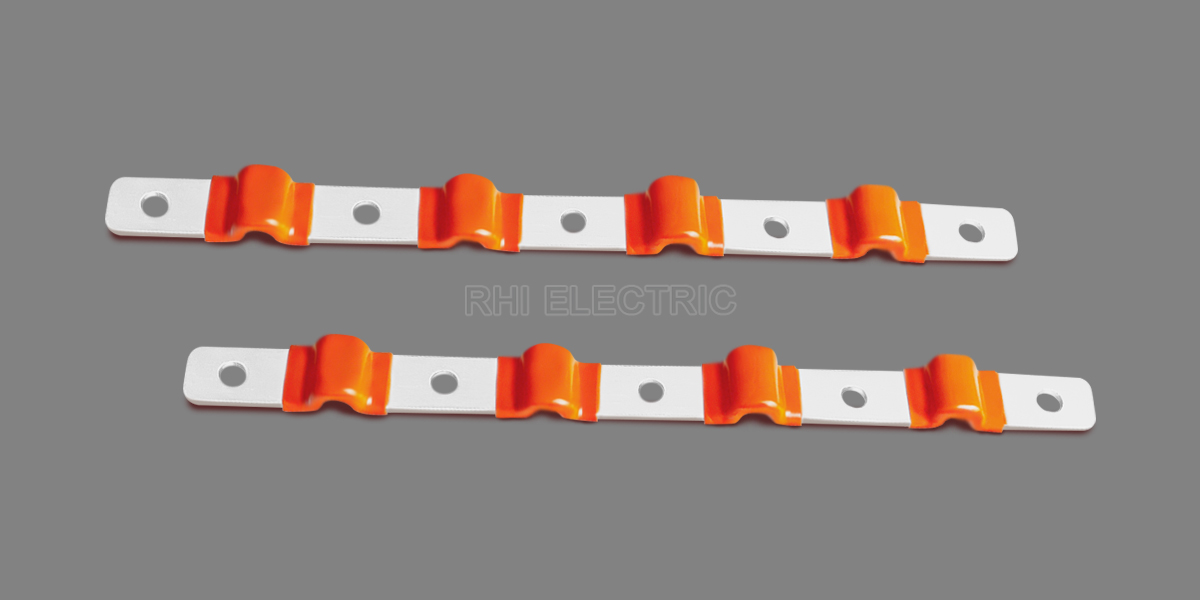

Flexible Aluminium Busbar with Heat-Shrink Insulation

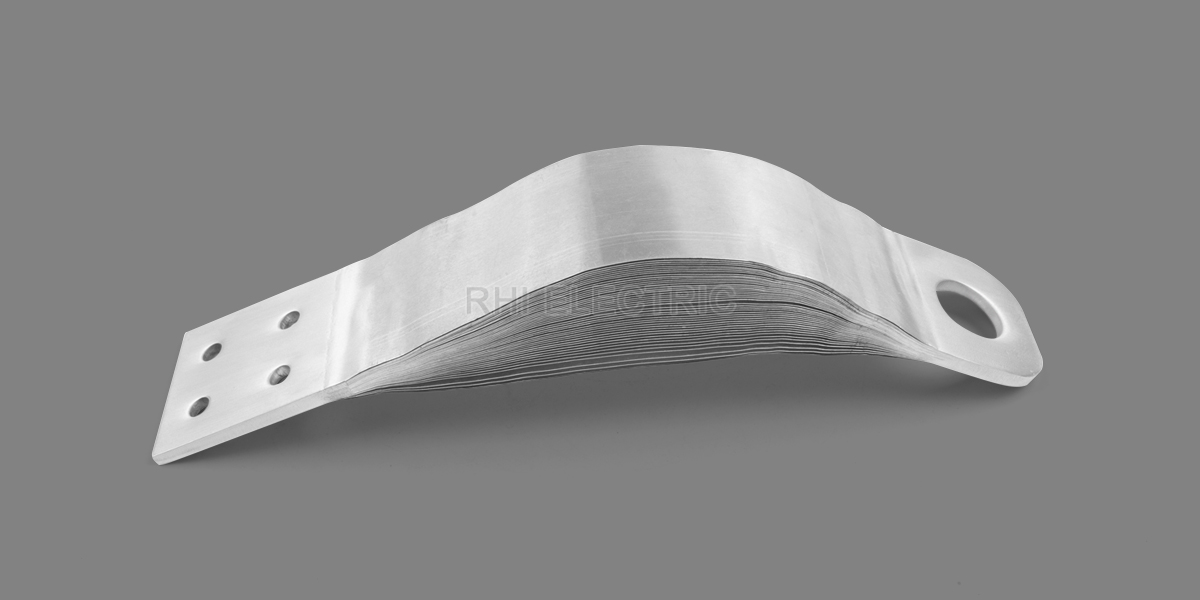

Flexible busbars are made from laminated aluminium strips with diffusion-welded terminals, ensuring low contact resistance and high mechanical reliability. The aluminium busbars provide excellent conductivity, thermal performance, and vibration resistance while accommodating thermal expansion and movement. With heat-shrink insulation, these busbars support compact designs and deliver durable, reliable power connections for EV battery packs, energy storage systems, and other high-reliability new energy applications.

The flexible busbar is constructed with 0.2 mm-thick aluminium strip as the conductive core, insulated by a tightly shrunk PE/EVA heat-shrink sleeve with a wall thickness of 1.0–1.5 mm. This insulation configuration complies with the manufacturing standards for new energy electrical interconnection components, delivering high reliability and safety performance as detailed below:

- Flame Retardancy Performance: The PE/EVA heat-shrink sleeve is rated UL 94 V-0 for flame retardancy, meeting the fire safety requirements of new energy battery packs and electric control systems to prevent flame spread in case of short circuits.

- Insulation Performance: Featuring a 1.0–1.5 mm PE/EVA insulation layer, the electrical busbar offers robust electrical performance with ≥100 MΩ insulation resistance at 1000 VDC and withstands 2500 VAC for 5 minutes under standard conditions (25°C, 50% RH). Its high theoretical dielectric strength (18–37.5 kVAC) provides substantial safety margin and ensures long-term reliability in demanding electrical and renewable energy applications.

- Structural Advantages: The heat-shrink sleeve adheres tightly to the surface of the flexible busbar, effectively isolating moisture, dust and other contaminants, and preventing creepage and short-circuit risks. The 0.2 mm aluminium strip core ensures excellent conductivity while maintaining the flexibility of the busbar for easy installation in confined spaces of new energy equipment.

- Application Scope: This flexible aluminium busbar i specifically designed for high-reliability new energy electrical interconnection scenarios, including battery module interconnection, power control unit (PCU) internal wiring, and energy storage system (ESS) current transmission components.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Working Temperature | Wall Thickness | Conductor Material |

| Values | 4000 V DC, 1 min | Qualified | UL94 V-0 | -50~125°C | 1.0-1.5mm | T2 Copper/Aluminium |

RHI Manufacturing Strength

RHI holds multiple internationally recognized certifications, including RoHS, REACH, UL94 V-0, ISO 14001, ISO 45001, and IATF 16949. With over a decade of industry expertise, RHI has established itself as a trusted Tier 1 supplier to leading enterprises in China and global markets. Our key customers include CATL in the power battery sector, the Renault–Nissan Alliance in the automotive industry, and Trinasolar in the energy storage sector, reflecting our proven capabilities and long-term reliability.

.jpg)