Aluminium Busbar Heat Shrink Insulated Flexible Connectors

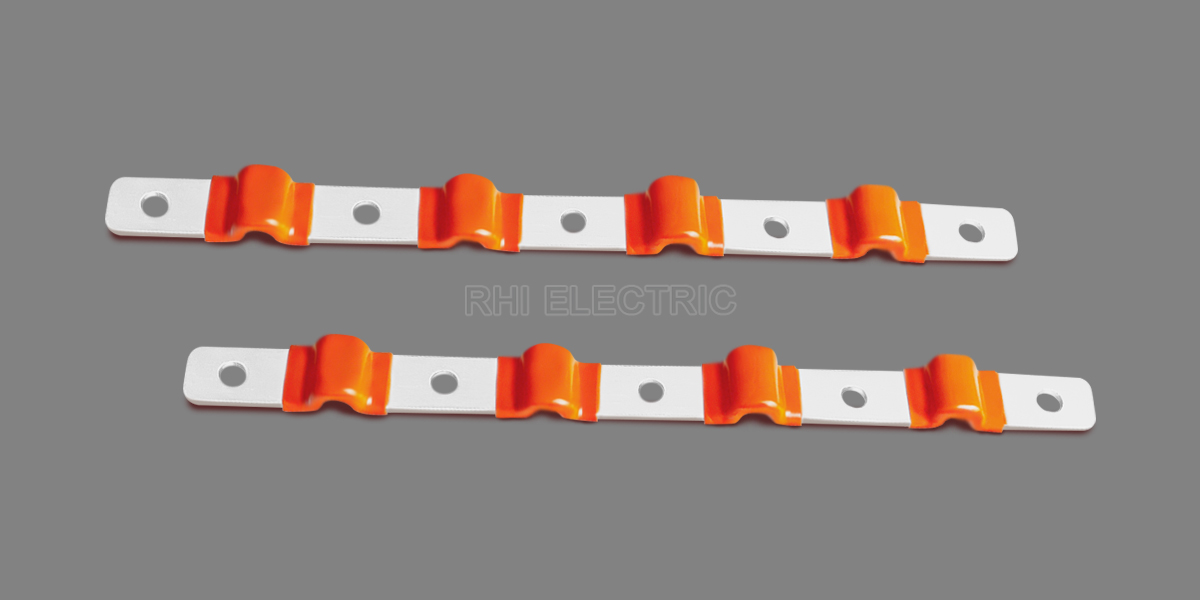

The aluminium busbar is formed from laminated aluminium foils with integrally welded terminals and a smooth, defect-free surface, ensuring reliable connections. Insulated with a tight-fit orange UL94 V-0 heat-shrink sleeve, it delivers ≥100 MΩ insulation resistance at 1000 VDC and 2500 VAC dielectric strength for high-reliability new energy applications.

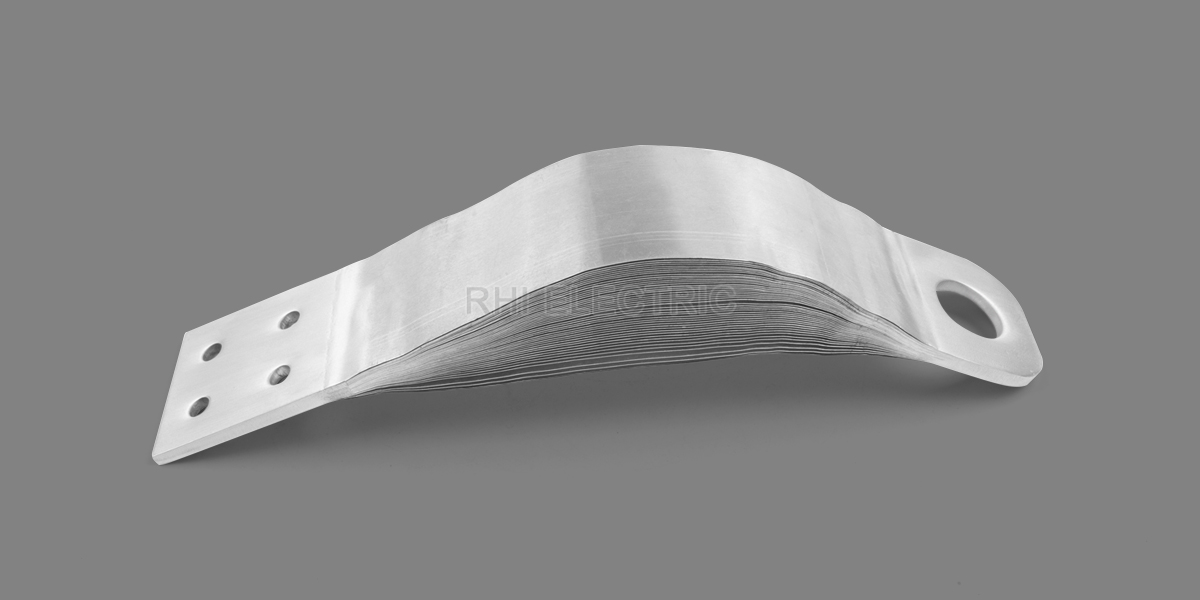

The flexible aluminium busbar is manufactured from laminated thin aluminium foils with integrally welded terminals. It features a smooth, uniform surface free of sharp edges, burrs, cracks, plating defects, or delamination, ensuring robust and reliable terminal connections.

The flexible busbar is insulated by a tightly shrunk orange heat-shrink sleeve rated UL 94 V-0 for flame retardancy. It delivers an insulation resistance of ≥100 MΩ at 1000 VDC and a dielectric withstand voltage of 2500 VAC (5-minute test without breakdown), making it ideal for high-reliability new energy electrical interconnection applications.

Application Advantages

- Battery Packs

Designed for compact layouts and assembly tolerances; flexible bending enables dimensional compensation. - Energy Storage Systems (ESS)

Laminated multi-layer structure improves high-current carrying capability by mitigating skin effect. - Industrial Power Devices

Arch-shaped design absorbs thermally induced stress; nickel-plated surface enhances corrosion resistance and environmental durability.

Structural Composition

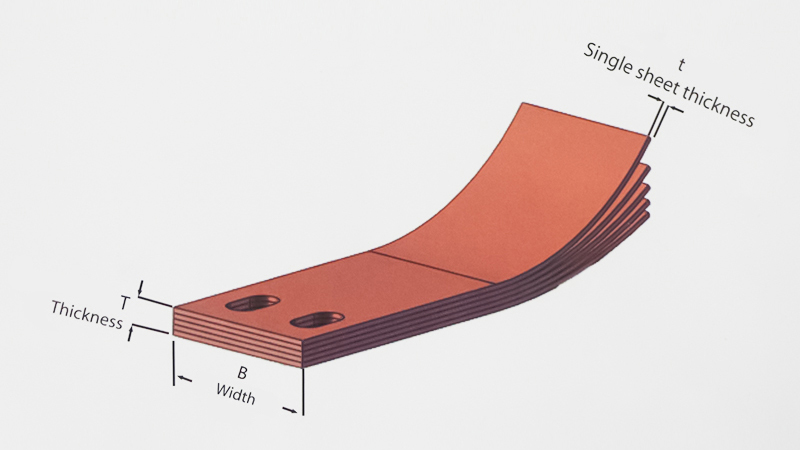

- Conductor Layers

Stacked from 10–50 layers of 0.2 mm thick 1060 pure aluminium foils (Al ≥99.95%); welded foil terminals with nickel-plated surface to improve mechanical strength and wear resistance. - Insulation

Standard EVA heat-shrink tubing (temperature range: –55 °C to 125 °C, dielectric strength ≥3 kV); mica tape or ceramic composite tape available for high thermal insulation requirements.

|

Material |

Single Sheet Thickness(t) |

Width(B) |

Thickness(T) |

||||||||

|

Al strip |

0.2 |

18 |

22 |

28 |

30 |

35 |

40 |

45 |

48 |

60 |

1~10 |

Mechanical Performance

- Interlayer peel strength ≥12.5 N (25 mm width, tested at 90° or 180°)

- No internal fracture or delamination after fatigue durability testing

Electrical Performance

-

Aluminium foil conductivity:

≥59% IACS (≈34.1 MS/m) for thickness ≤1.5 mm

≥57% IACS (≈32.9 MS/m) for thickness >1.5 mmi -

Rated current verification: no damage or plating peeling during operation; temperature rise and insulation resistance meet specified standards