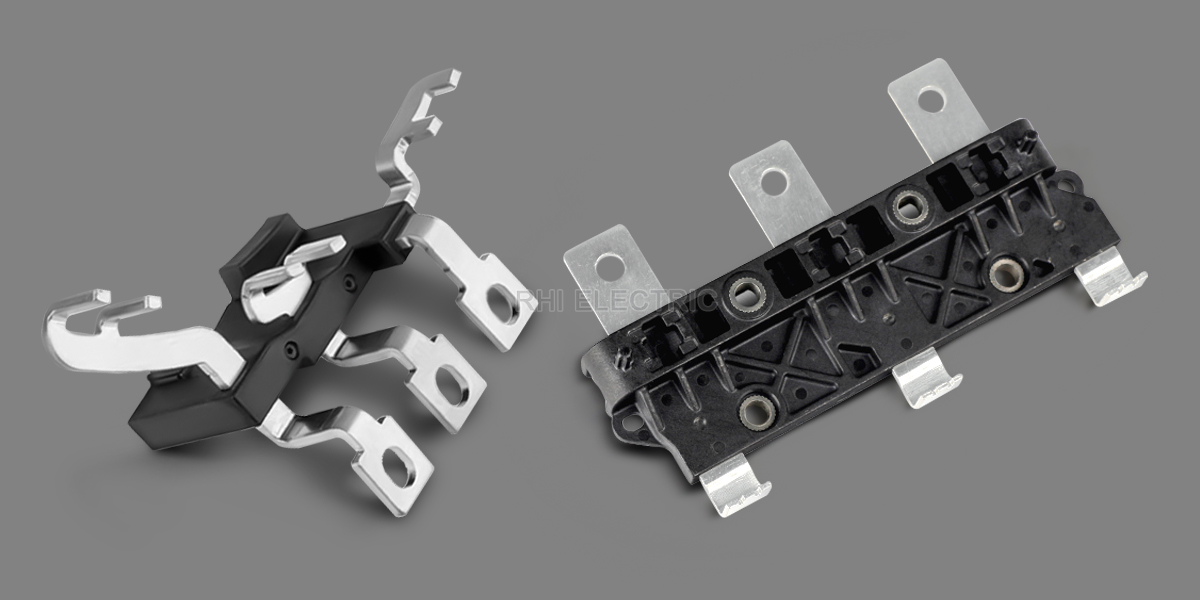

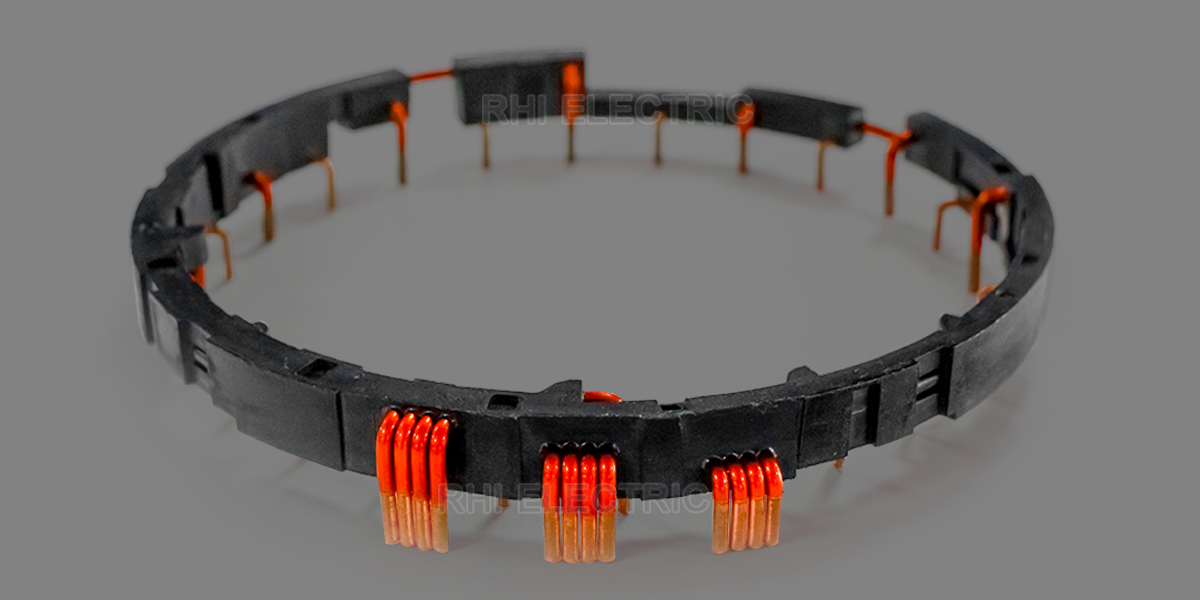

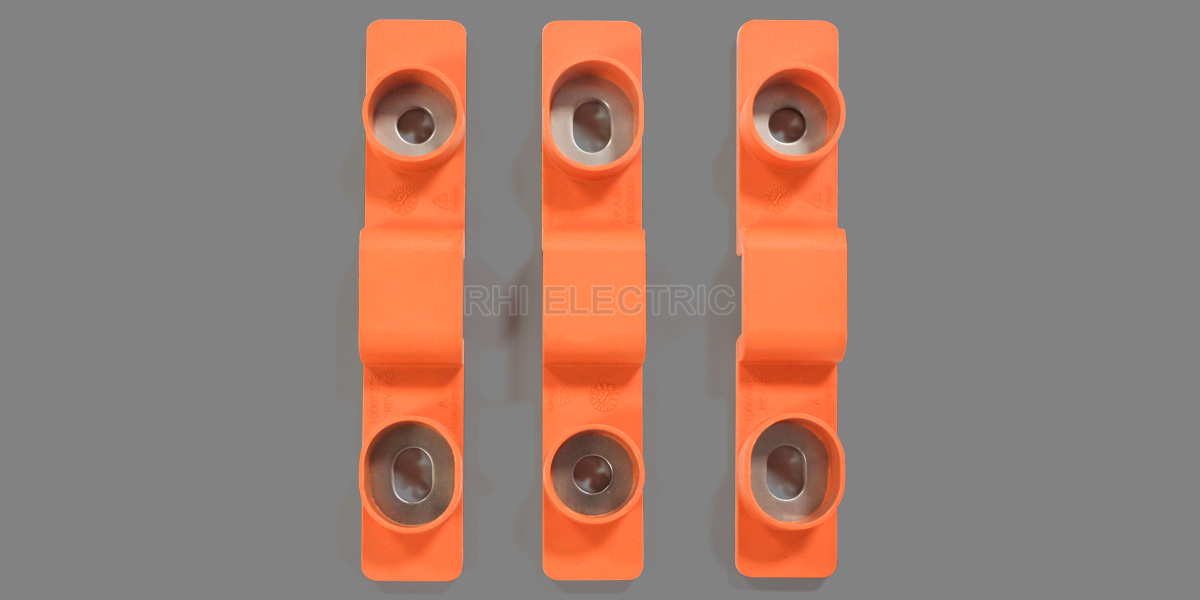

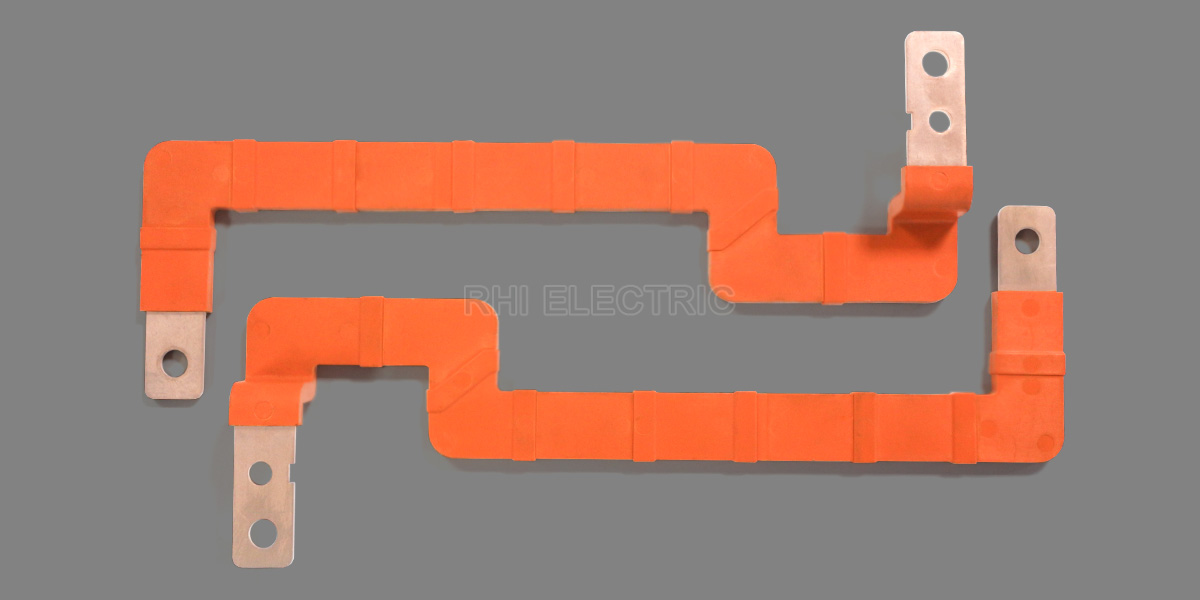

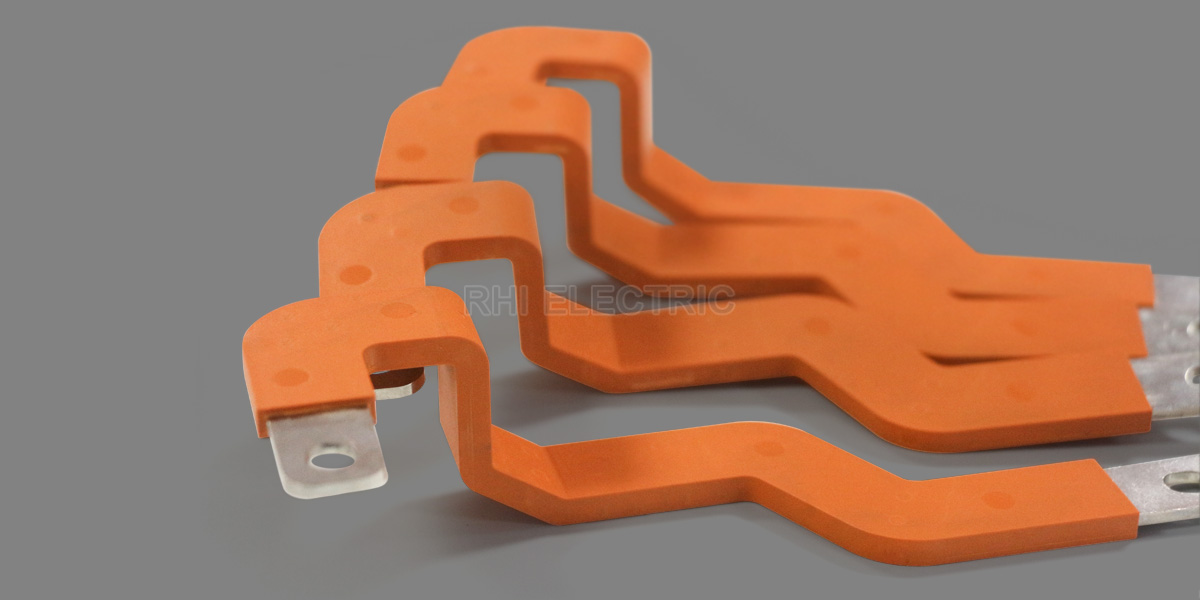

Battery Busbars, Overmolded Insulated Copper Busbar Connectors

Overmolded copper busbars transmit high voltage power in EV battery packs. The process encapsulates copper conductors in plastic, forming one solid piece. This allows high current flow and prevents electrical leakage. The plastic housing resists stress and vibration, keeping components aligned. By replacing wire harnesses, copper busbars conserve space and permit automated assembly.

In EV battery packs, overmolded copper busbars serve as key high-voltage conductors. Using insert-molding, engineering plastics encapsulate the copper to form a sealed, integrated structure. The high-purity copper ensures stable large-current transmission, while the molded insulation prevents high-voltage leakage and enhances system safety. The encapsulation also protects the conductor from vibration and mechanical stress, improves installation stability, and replaces dispersed wiring to optimize pack layout and automated assembly efficiency.

Click here to view the product video of this busbar.

Key Material Requirements

- Insulation performance: Meets high-voltage electrical insulation standards with stable dielectric strength.

- Toughness: Improved impact resistance to prevent brittle failure under vibration or low-temperature conditions.

- Rigidity: Glass-fiber or similar reinforcement to ensure structural strength and long-term mechanical stability.

- Heat resistance: Suitable for battery-pack operating temperatures (120–180 °C) and high-temperature zones.

- Flowability: Supports thin-wall and complex overmolding with reduced risks of voids or short shots.

- Metal–plastic adhesion: Optimized formulations to ensure strong bonding to copper conductors with no delamination.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Operating Temperature | Insulation Material | Conductor Material |

| Values | AC 1000V | Qualified | UL94 V-0 | -40 °C–120 °C (max 150 °C) |

PA66 + GF30 |

T2 Copper |

To meet the stringent requirements of busbar insulation components, RHI’s PA66+GF30 (30% glass-fiber reinforced, halogen-free flame-retardant) material offers excellent compatibility:

- Superior electrical insulation: Delivers stable high-voltage protection and meets vehicle electrical-safety standards.

- High temperature resistance: Supports continuous use at 150–180 °C (HDT >270 °C) while maintaining rigidity, strength, and dimensional stability.

- Low expansion & anti-creep: Low CTE and excellent creep resistance ensure precise dimensions and secure conductor fixation across wide temperature ranges and long-term loads.

- High flame retardancy: Halogen-free formulation achieves UL94 V-0 at 0.8 mm, effectively limiting flame spread.

- Balanced mechanical properties: Combines high stiffness, strength, and required toughness for structural support and impact resistance.

- High flowability: High-flow PA66 grade enables molding of complex and thin-wall insulation parts, improving efficiency and yield.

- Strong metal–plastic bonding: Designed for insert molding to ensure durable adhesion to copper conductors for long-term reliability.