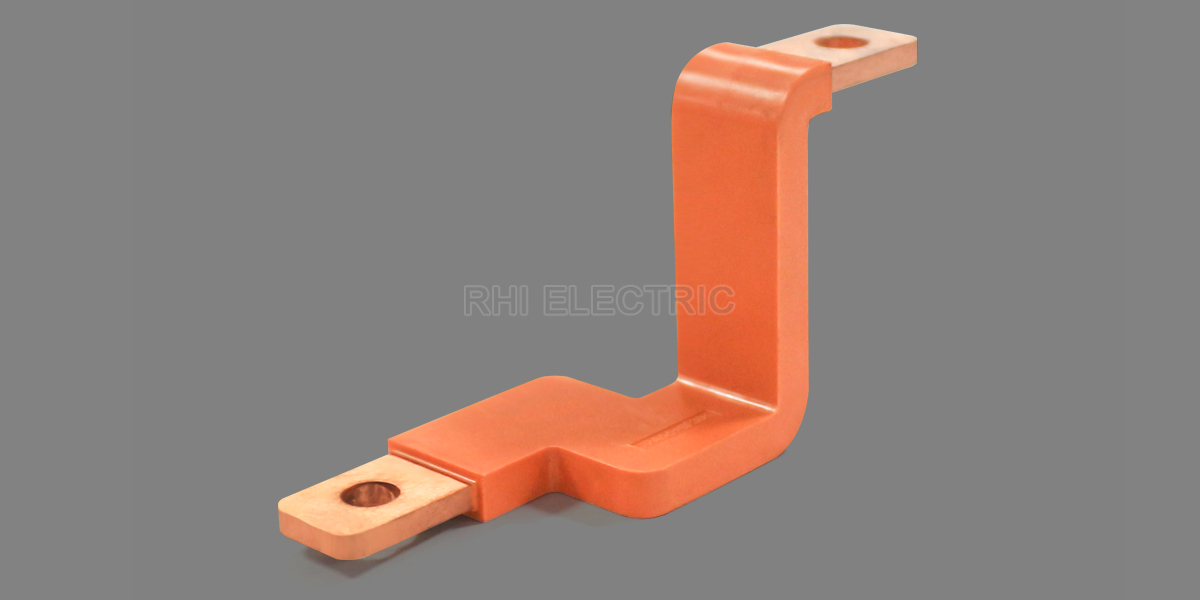

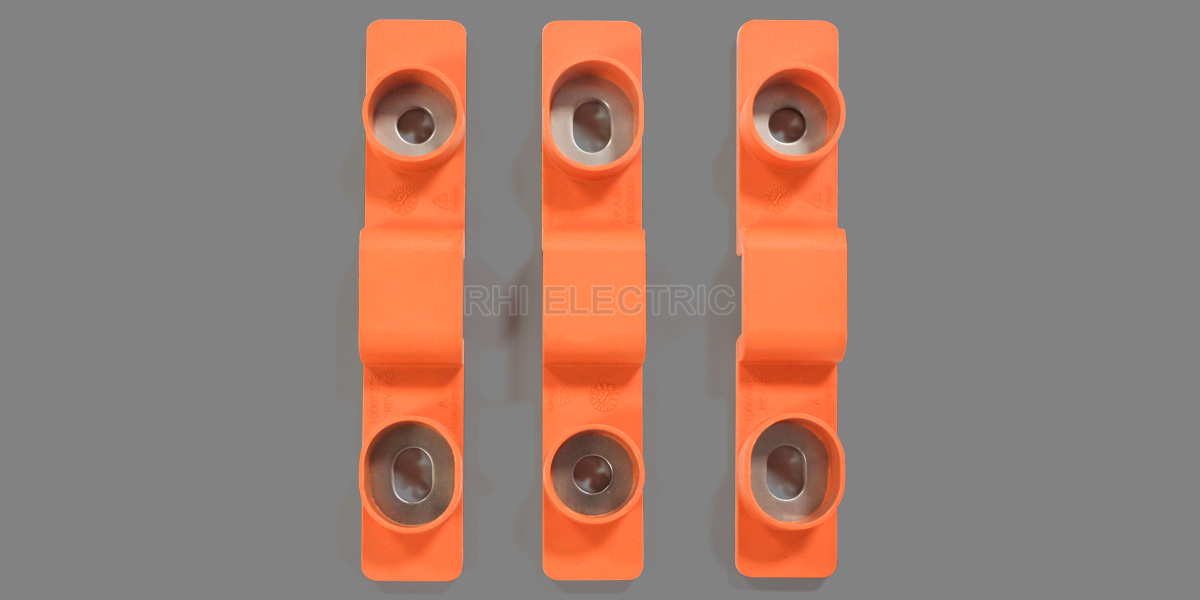

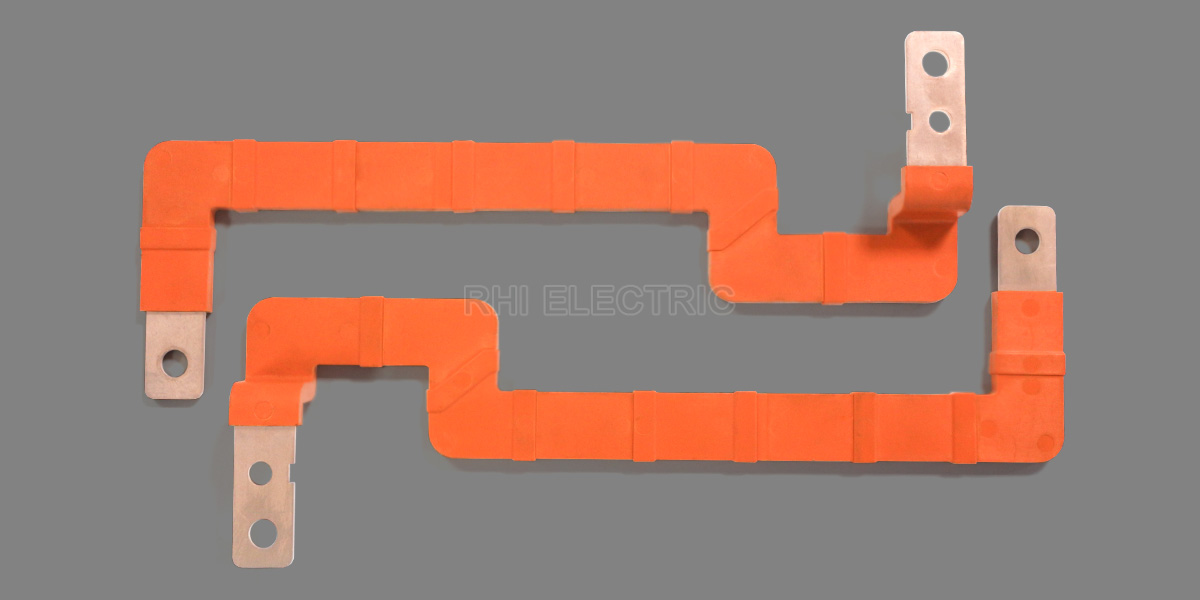

Busbar Overmolded with Insulation for EV Motor and Battery Systems

This copper busbar is designed for EV drive systems, using PA66+GF30 for enhanced strength, heat resistance, and moldability. The material increases flexural strength by over 50% and raises the heat deflection temperature above 150 °C, ensuring stable performance under heat and vibration. Injection-molded for tight encapsulation and strong insulation, it delivers durability and reliability. Widely applied in high-voltage motors, controllers, and battery packs, insulated busbar enables compact design, high power density, automated assembly, and flexible customization for EV systems.

This copper motor busbar is designed for high-performance EV drive systems, using PA66 reinforced with 30% glass fiber (PA66+GF30) for superior mechanical strength, heat resistance, and processability.

The reinforcement improves flexural strength by over 50% and raises the heat deflection temperature above 150 °C, ensuring stable performance under high temperature and vibration.

Manufactured through vertical injection molding, the copper conductor is fully encapsulated with a uniform, void-free insulation layer, delivering reliable dielectric strength and mechanical durability.

Widely applied in high-voltage traction motors, controllers, and battery packs, this electrical busbar enables compact, high-density power interconnections, supports automated assembly, and offers customizable designs for diverse EV system configurations.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Operating Temperature | Insulation Material | Conductor Material |

| Values | AC 1000V | Qualified | UL94 V-0 | -40 °C–120 °C (max 150 °C) |

PA66 + GF30 |

T2 Copper |

Key Features

- High Mechanical Strength: 30% glass fiber–reinforced PA66 (PA66+GF30) insulation increases flexural strength by over 50%.

- Excellent Heat Resistance: Heat deflection temperature ≥150 °C ensures stability under high temperatures.

- Good Moldability: Enables precise injection molding with tight copper–insulation bonding.

- Reliable Electrical Insulation: Vertical molding eliminates air gaps for superior insulation.

- Long-Term Stability: Maintains mechanical and electrical performance under heat and vibration.

- Customizable Design: Supports tailored dimensions and layouts for different system requirements.

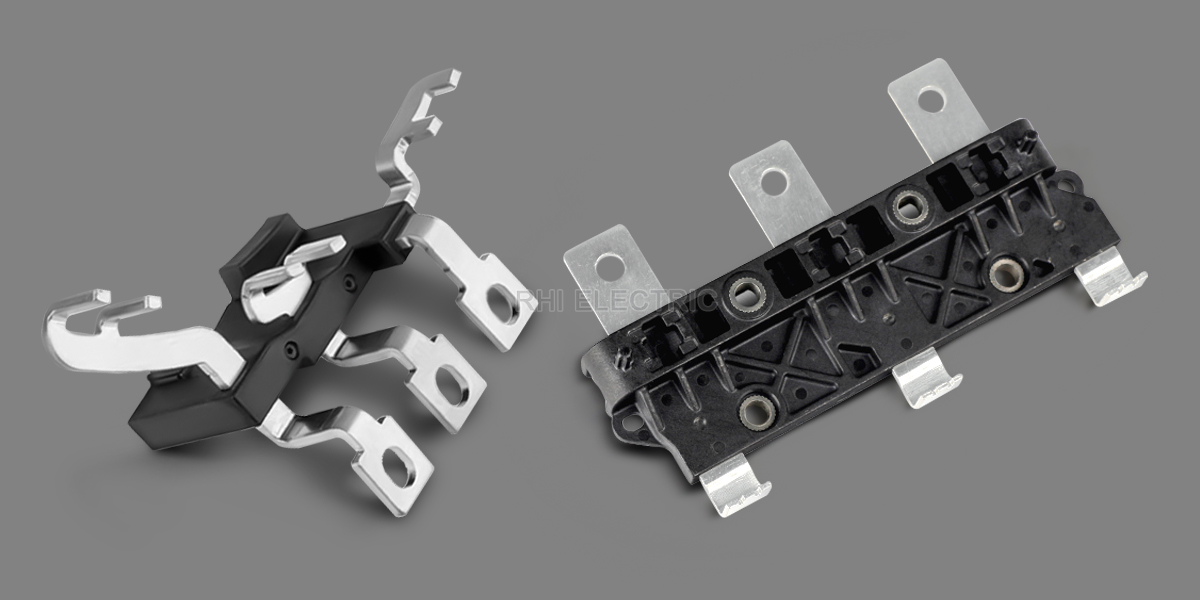

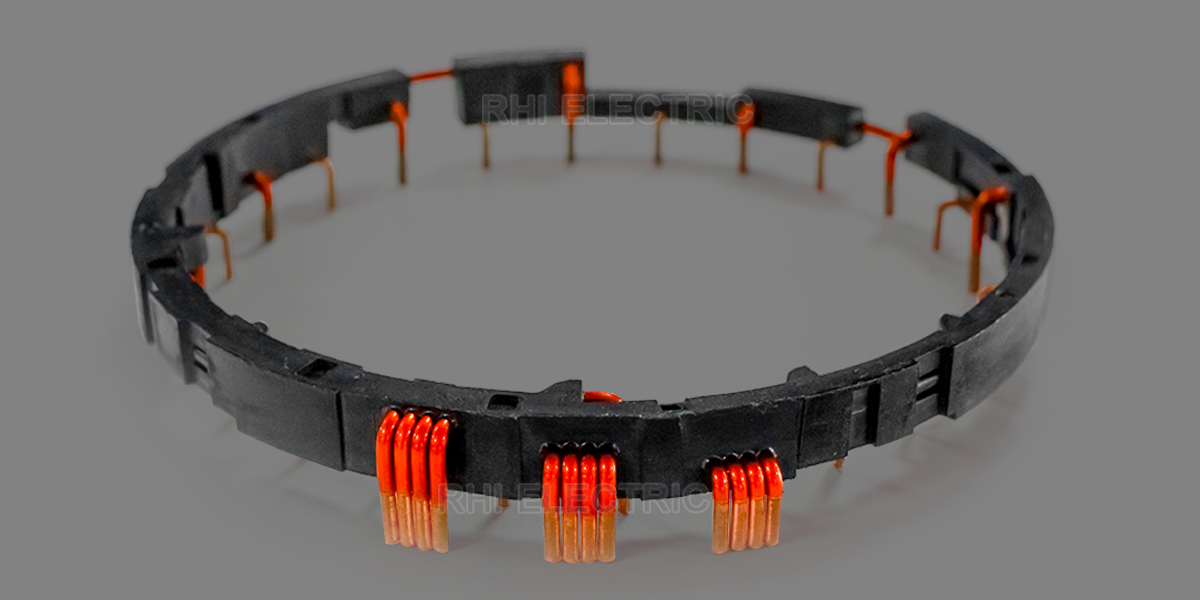

Applications

- High-voltage motor connections

- Energy transfer between motor controllers and battery packs

- Automated assembly of energy storage systems