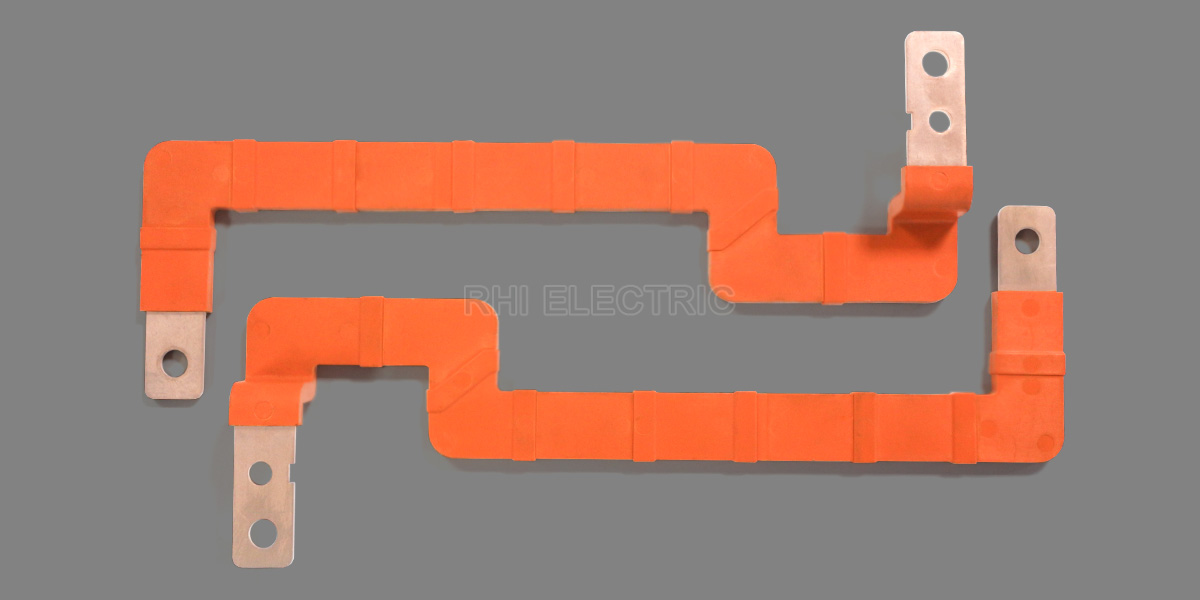

Copper Busbar for EV Motors

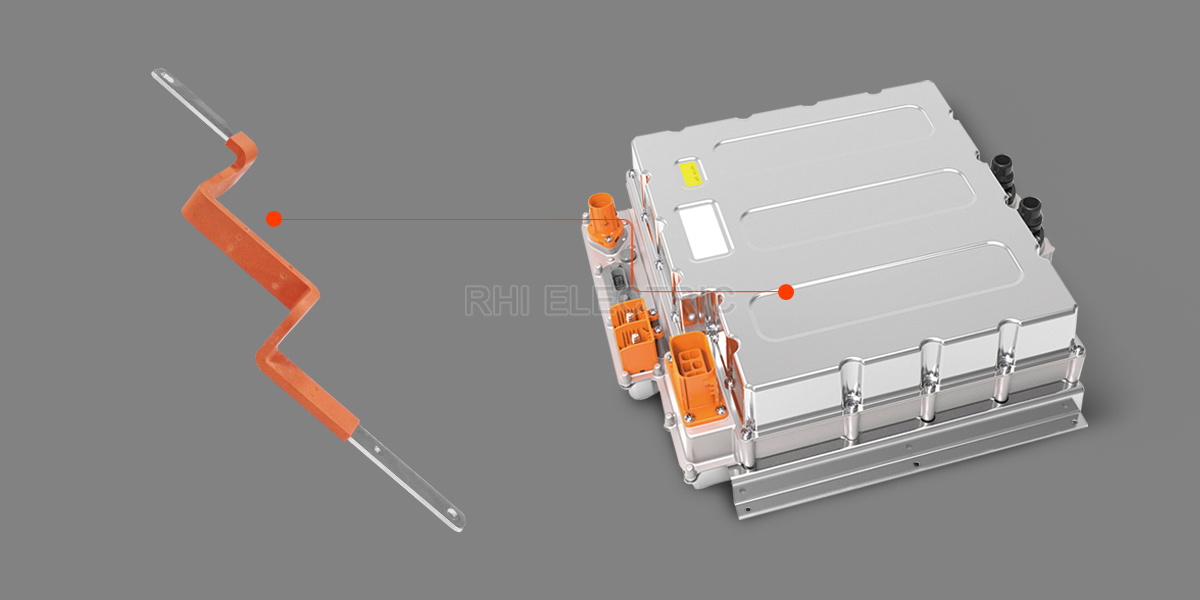

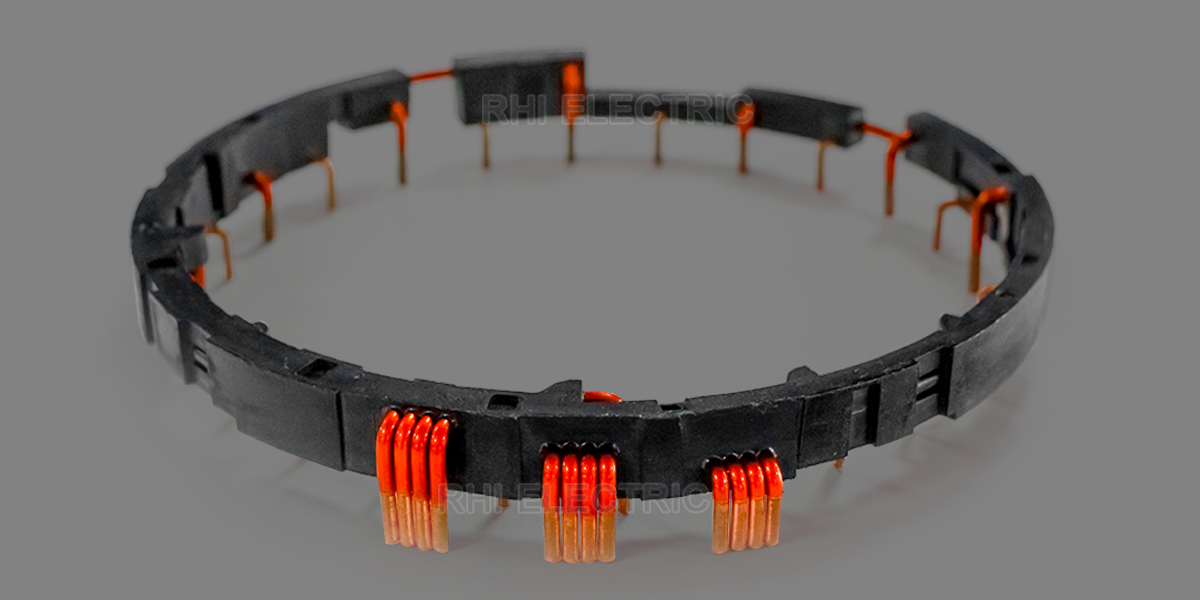

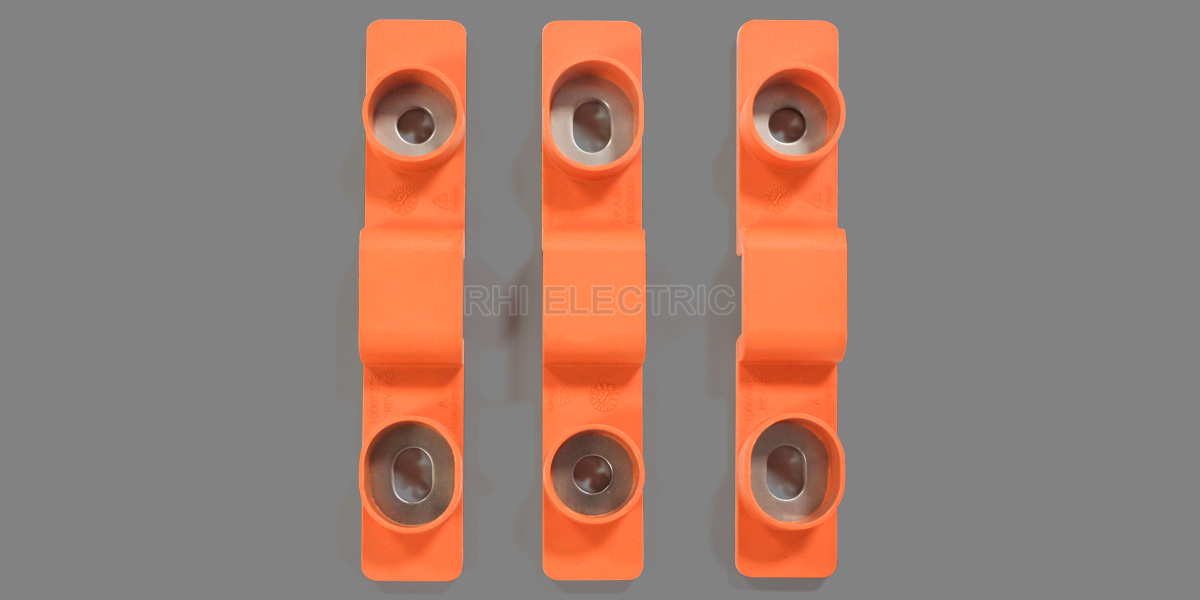

This copper motor busbar is engineered for high-performance EV drives, made from PA66 reinforced with 25% glass fiber to provide excellent insulation and reduced weight. Widely applied in high-voltage traction motors and IDMs, it enables flexible interconnections for controllers, battery packs, and hairpin motors. With seamless integration into system designs and full customization to specifications, motor busbar enhances power density while supporting production automation.

Copper Motor Busbar for EV Drives: Insulated, and Customizable

This copper motor busbar is designed for high-performance EV drives, using PA66 with 25% glass fiber for excellent insulation and high strength. It is widely used in traction motors and IDMs, enabling flexible connections to controllers, battery packs, and hairpin motors.

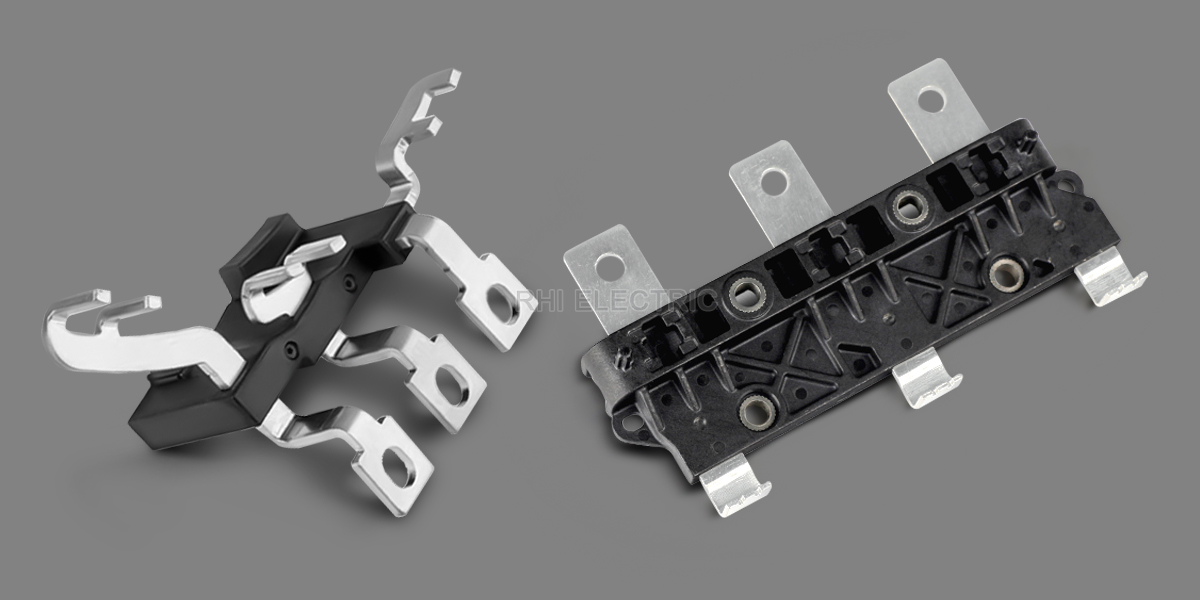

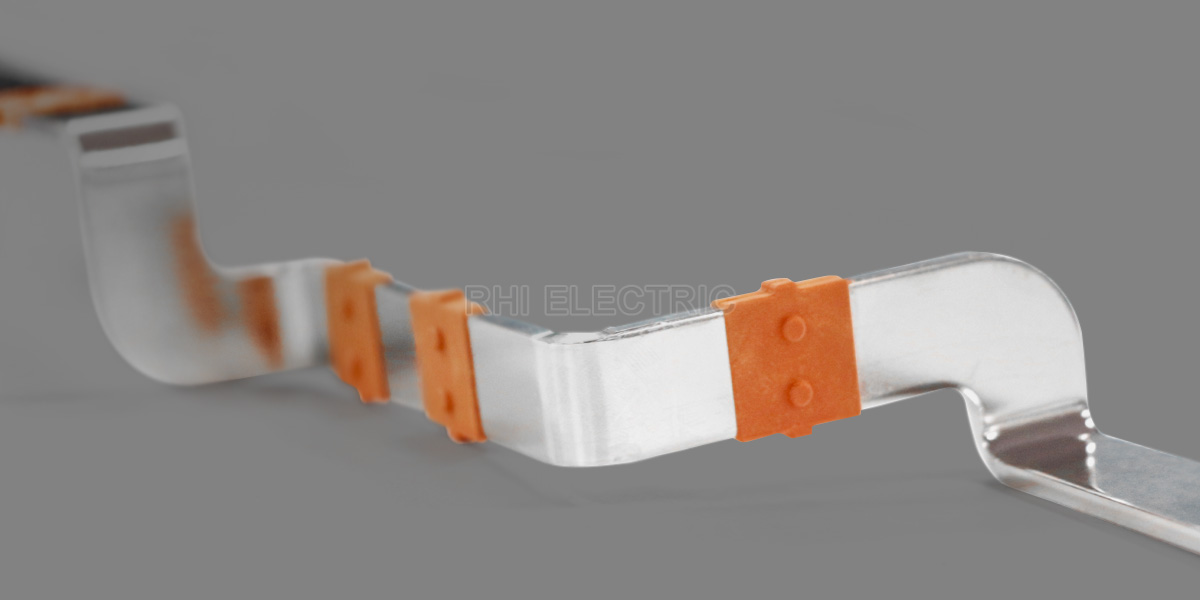

Produced on vertical injection molding machines, the copper busbar adopts a two-step injection process: the first secures the conductor, the second fully encapsulates the copper. This ensures reliable insulation, strong mechanical performance, and easy system integration, while supporting customization, higher power density, and automated production.

👉 Click here to view motor busbar product video.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Operating Temperature | Insulation Material | Conductor Material |

| Values | AC 1000V | Qualified | UL94 V-0 | -40 °C–120 °C (max 150 °C) |

PA66 + GF25 |

T2 Copper |

Application

- Motor Connections: In EV drive motors, injection-molded copper busbars provide reliable electrical connections while withstanding long-term vibration and mechanical stress. Using high-performance insulation materials such as PA66+GF or PPS+GF, they ensure excellent thermal resistance, mechanical strength, and insulation, enabling safe and efficient connections between stator windings and the high-voltage supply.

- Battery Pack Connections: In battery systems, injection-molded busbars interconnect cells and modules at high voltage, requiring superior conductivity and corrosion resistance to minimize contact resistance and improve energy efficiency. The molded insulation layer enhances protection, prevents short circuits, and ensures safe, reliable operation during charge and discharge cycles.

- Controller Systems: In EV controllers, injection-molded busbars link the controller with both motor and battery pack under demanding conditions. Their design combines thermal resistance, EMI shielding, and compact structure. Custom molding enables highly integrated interconnections that support high current capacity while improving power density and system space utilization.