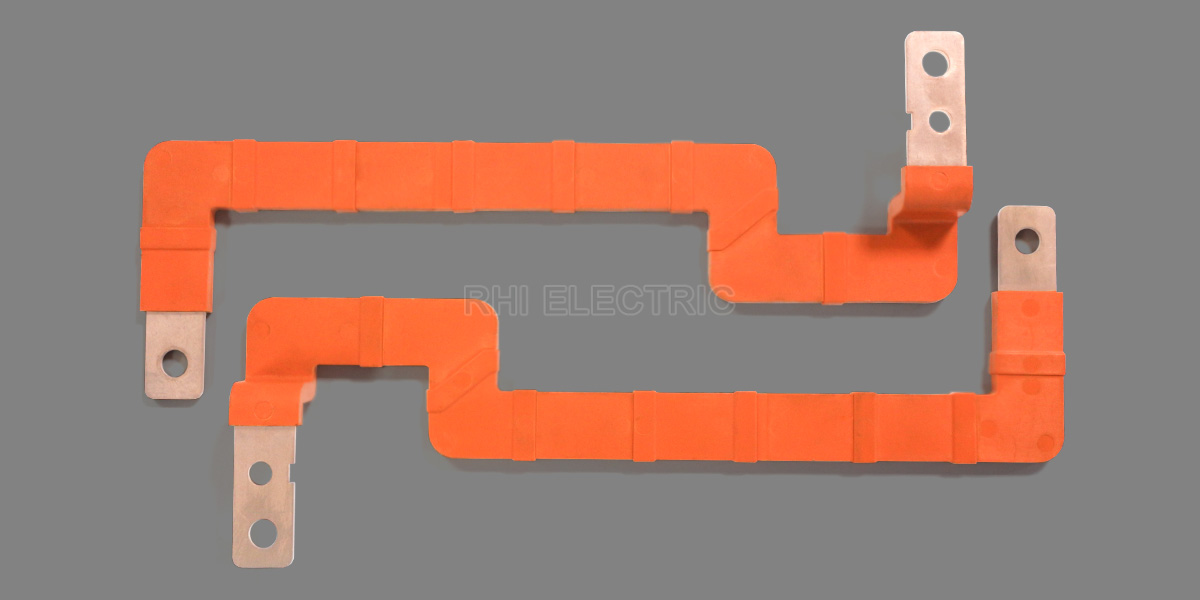

Motor Connection Busbar: Enamelled Wire Overmolding

Overmolded enamelled wire busbars provide reliable, fully insulated connections for EV drive motors, controllers, battery packs, and flat-wire motors. The one-step injection molding integrates insulation, sealing, and reinforcement, simplifying assembly and improving durability. Made of PPS with 40% glass fiber, these busbars offer excellent thermal stability, mechanical strength, and electrical reliability under demanding conditions.

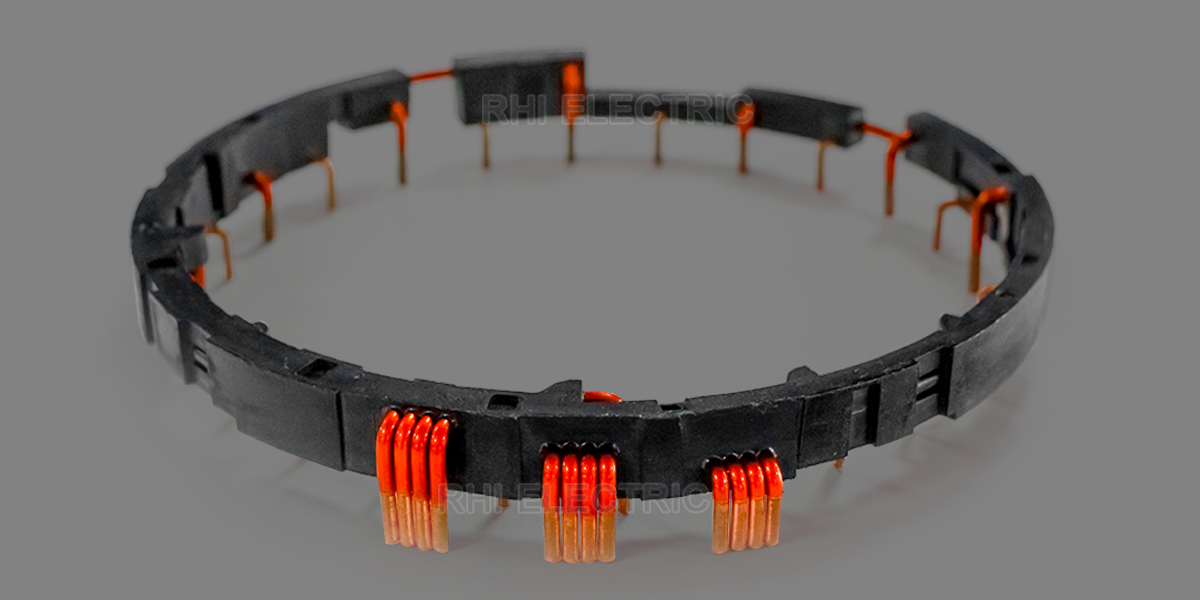

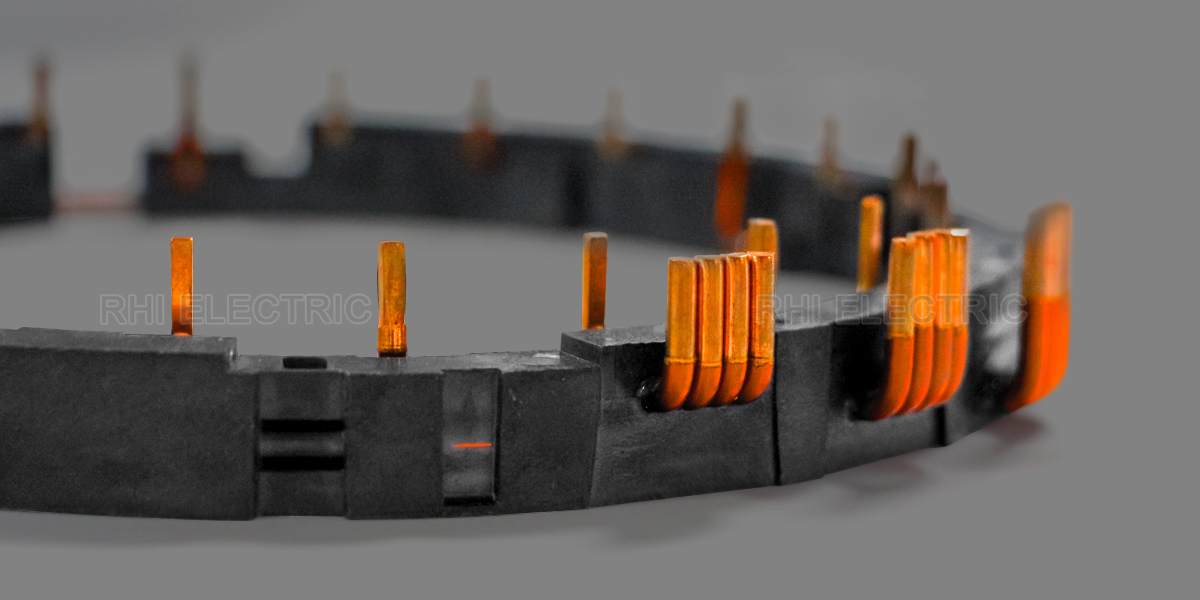

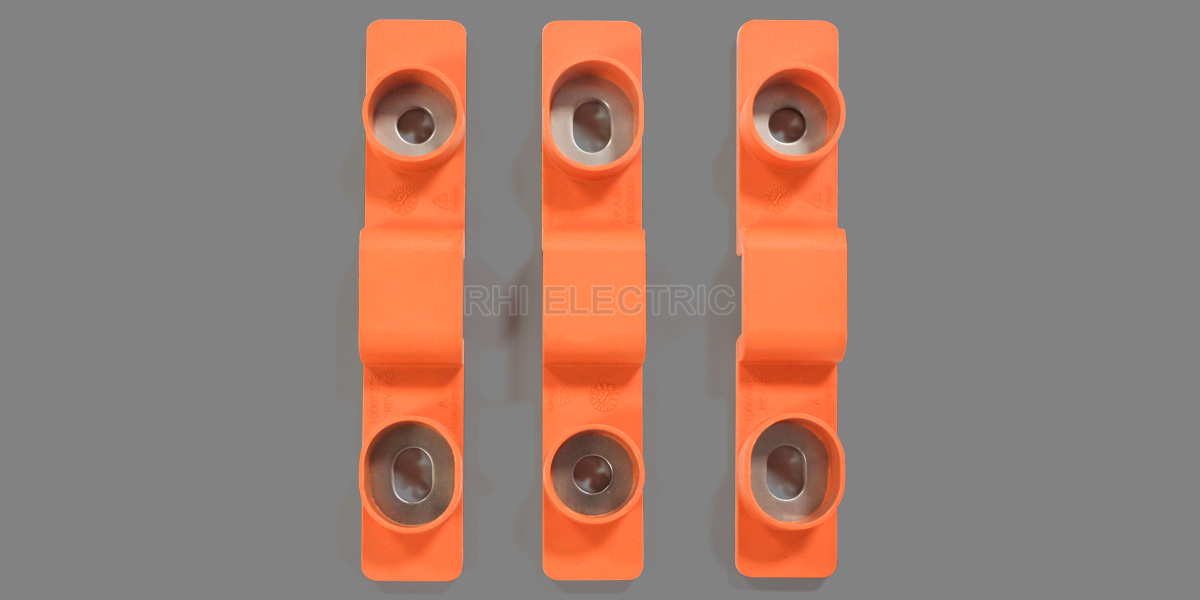

Overmolded Stator Busbar for High-Performance EV Drives

This motor stator busbar combines lightweight design, high reliability, and full customization—engineered for high-performance EV drive applications.

Manufactured with PPS + 40% glass fiber, it delivers excellent electrical insulation and reduced weight.

The overmolded copper busbar efficiently and reliably connects stator windings to the high-voltage supply, widely applied in traction motors and integrated drive modules (IDMs).

The motor busbar enables flexible phase connections, multiple soldering pad options, and tailored forming solutions for hairpin motors.

Seamlessly integrable into system designs and customizable to customer specifications, it is an ideal solution to enhance power density and production automation in electric drive systems.

👉 Click here to view motor busbar product video.

Process Principles & Advantages

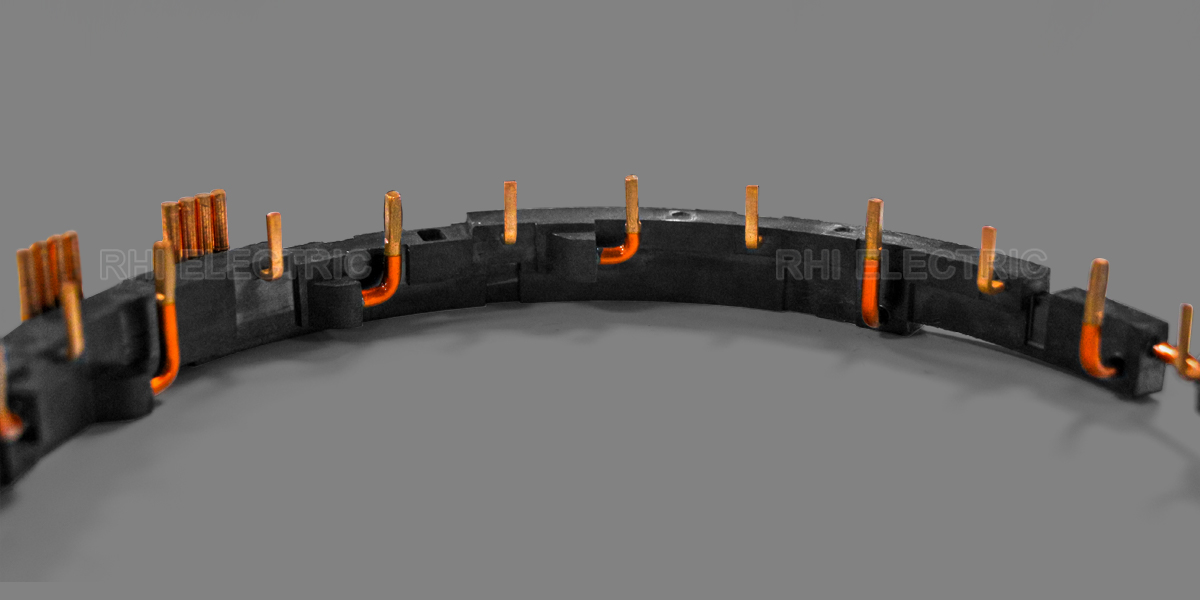

- Enamelled wire overmolding involves encapsulating wire lead-outs using custom molds to form a unified insulation structure. Its key benefits include:

- Enhanced Insulation: Dual insulation layers (molded + enamel coating) significantly improve dielectric strength for high-voltage environments.

- Improved Mechanical Stability: The molded body secures the leads against pull force, vibration, and thermal expansion-induced displacement.

- Moisture and Dust Sealing: Complete encapsulation prevents ingress of moisture, dust, and condensation—enhancing environmental resistance.

- Automation Friendly: The process is stable and controllable, easily integrated with automated winding and welding lines for consistent, high-volume production.

| Parameter | Resisitance to High Temperature | Insulation Withstand Voltage | RoHS | Flammability Rating | Working Temperature | Insulation Material | Conductor Material |

| Values | 158℃/168h | AC 1000V | Qualified | UL94 V-0 | -40~105°C 125°C/180°C | PPS + GF40 | T2 Copper/Aluminium |

Application Scenarios & Typical Structures

Injection molding is widely applied in EV motors for lead insulation, stator-to-terminal block connections, and the secure integration of wire harnesses, ensuring high reliability under vibration and thermal cycling. It’s especially effective in:

- EV stator end encapsulation

- Coil connections in energy storage inverters

- Industrial servo and compact motors

- Inductor and transformer winding lead-out fixation

The molded structure can be customized—point encapsulation, housing-style enclosures, or integrated plug-in designs—based on wire gauge, terminal configuration, and space constraints.

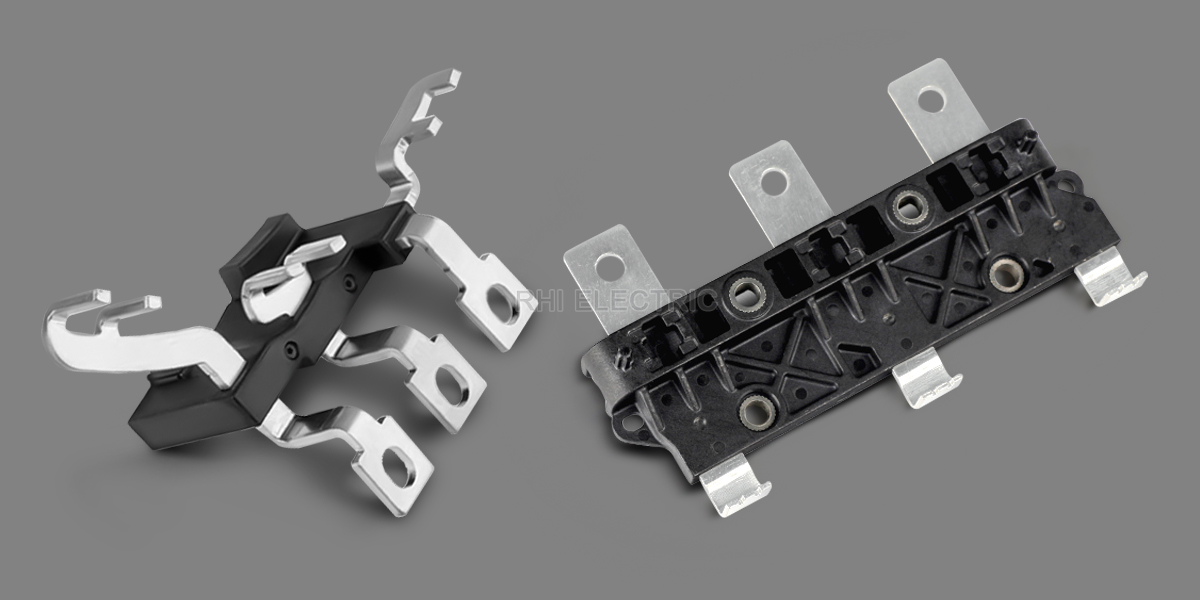

Integration with Busbar Manufacturing

In some power systems, enamelled wire leads must interface with copper or composite busbars. Overmolding not only provides structural protection but also facilitates subsequent crimping, soldering, or bolted connections—enhancing conductivity and assembly efficiency.

Why Choose RHI?

As a leading Chinese manufacturer of copper and aluminium busbars, RHI specializes in customized connection solutions for new energy batteries. Our technical capabilities and quality systems ensure reliable products for global customers.

Core Competencies:

1. Large-Scale Production Capacity

- 30,000+㎡ modern manufacturing facility

- Advanced automated production lines

- Capable of mass production for industry demands

2. Precision Manufacturing & Quality Control

- Full automation with CCD inspection systems

- Multi-stage quality management process

- IATF 16949, ISO 14001 & ISO 45001 certified

- Compliant with RoHS, REACH and UL94V-0 standards

3. Digital Manufacturing Systems

- Integrated ERP, PLM and MES platforms

- Optimized production efficiency and cost control

4. New Energy Specialization

- High-conductivity, heat-resistant busbar solutions

- Designed for EV batteries and energy storage systems

- Recognized as "Specialized & Innovative SME" (2023)

We focus on manufacturing excellence through innovation and quality to support the global transition to sustainable energy.