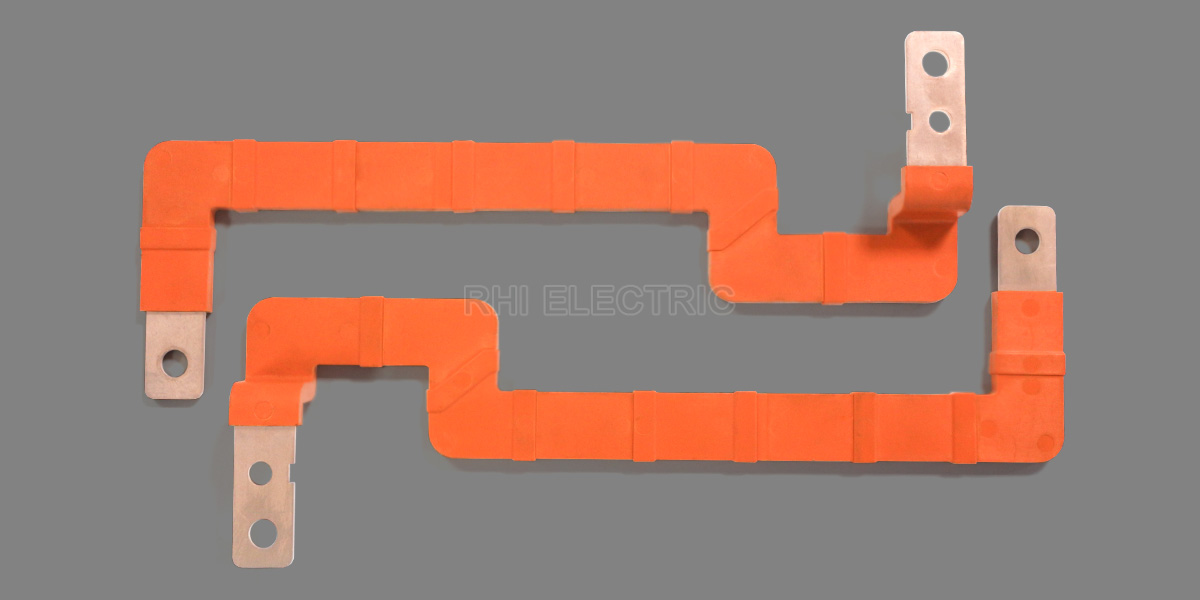

High-Voltage Copper Busbar for EV Battery Pack and Drive Motor

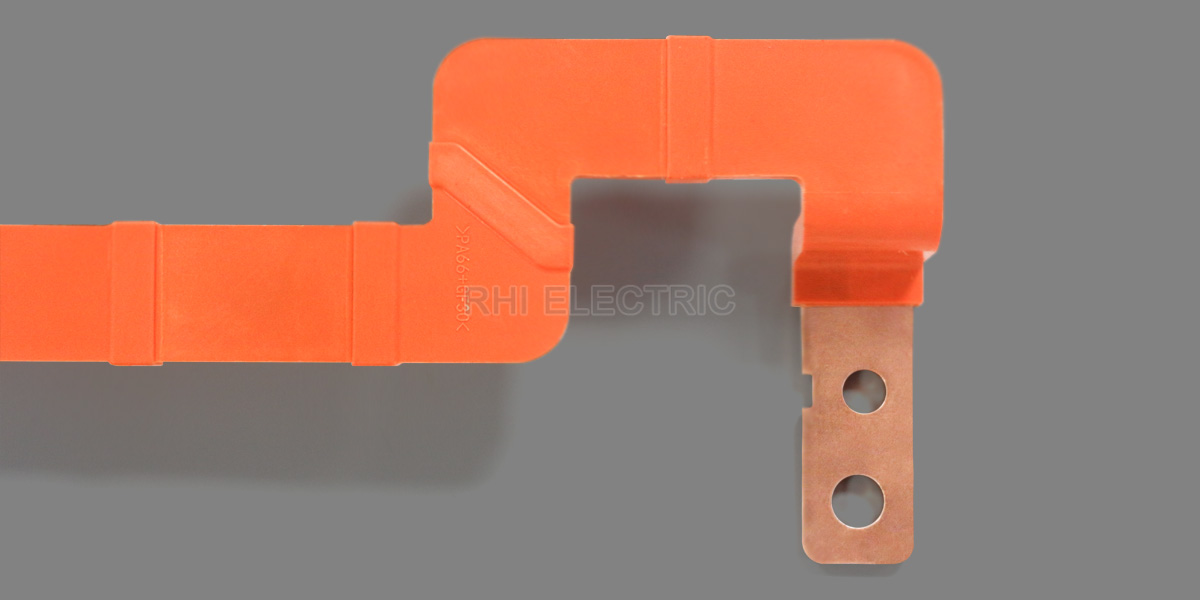

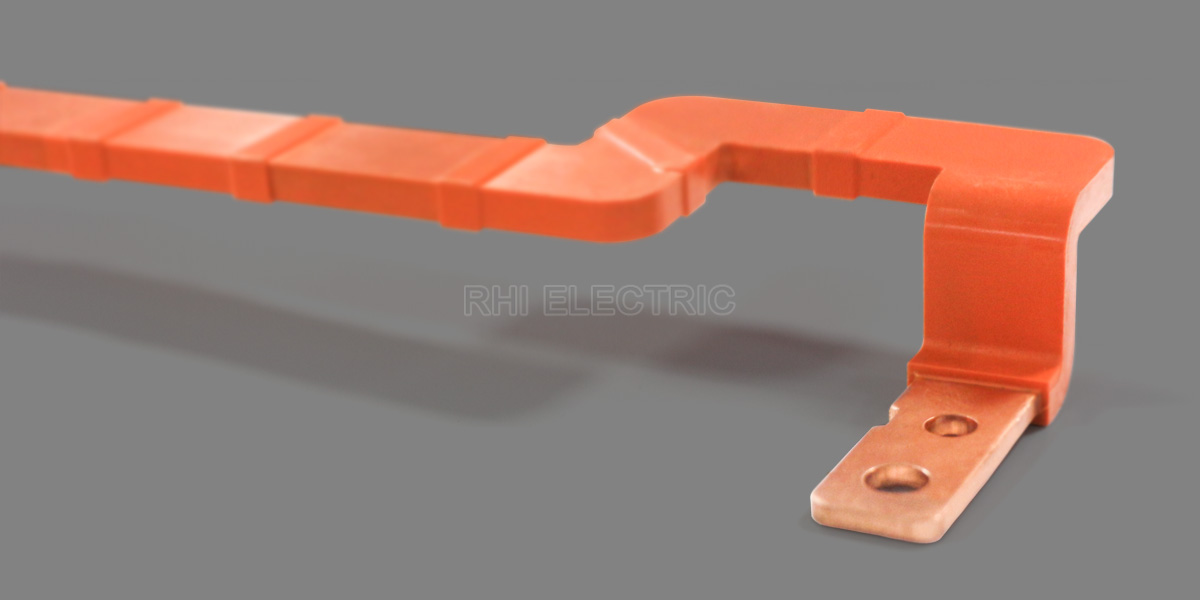

The copper busbar is engineered for new energy systems, including battery packs, drive motors, and ECUs. High voltage busbar allows for customized tooling and plating. The PA66+GF30 insulation provides excellent mechanical strength, heat resistance (HDT > 250 °C), and formability. Featuring over 50% greater flexural strength, the insulated busbar maintains reliable electrical and mechanical stability even under high-temperature and high-vibration conditions.

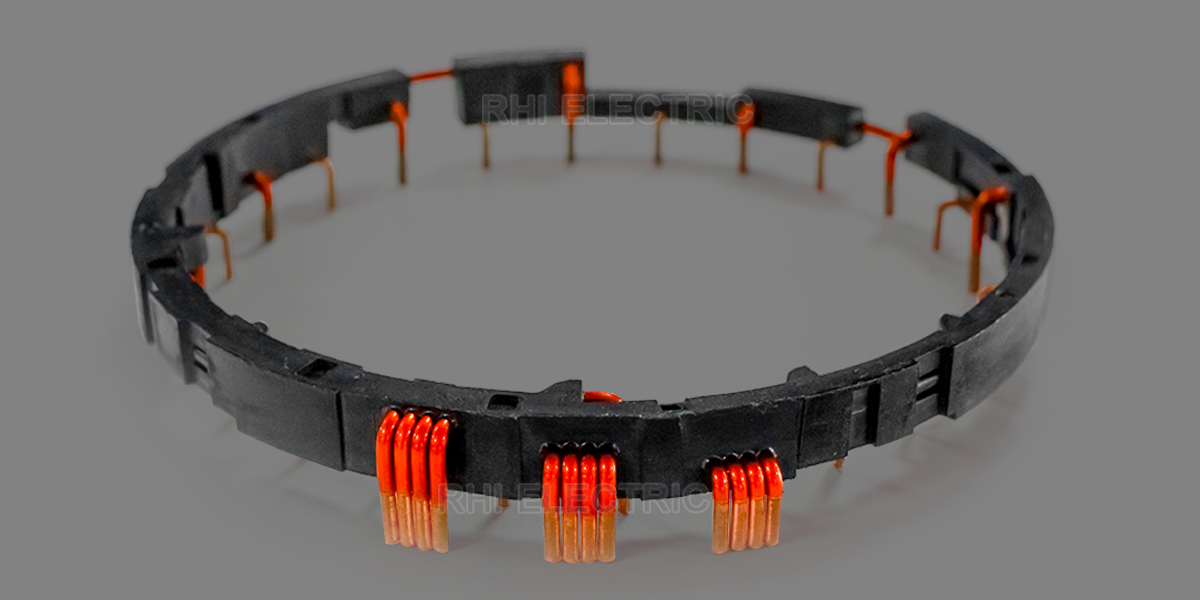

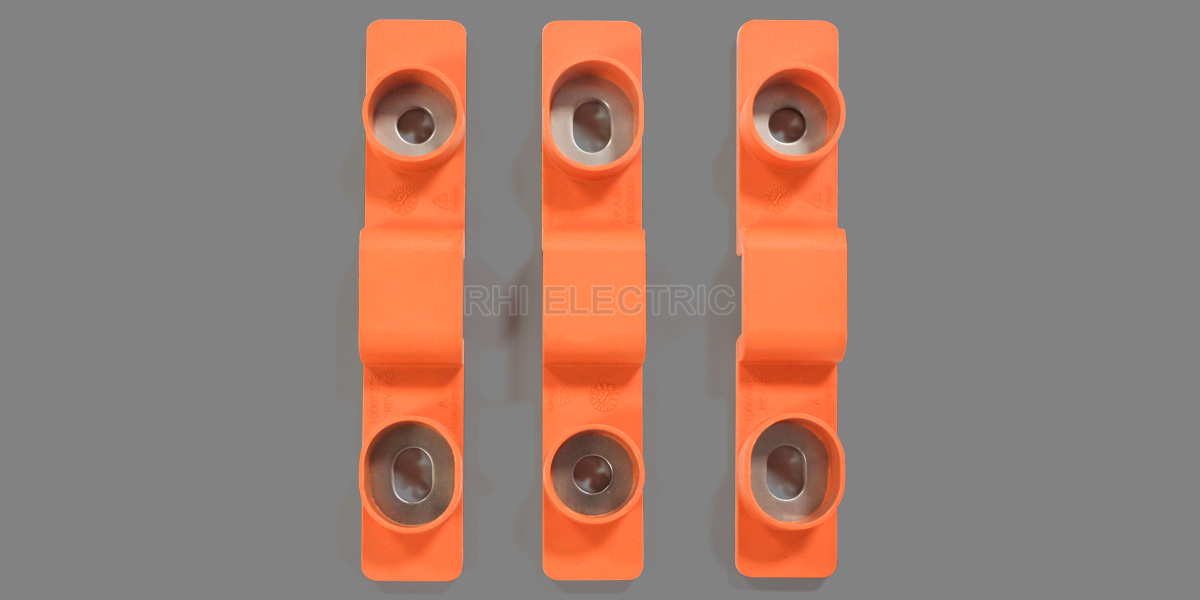

In EV battery packs, overmolded copper busbars serve as the core components for high-voltage current transmission. Through precision molding, high-performance engineering plastics are tightly encapsulated around copper conductors to form an integrated conductive structure. These electrical busbars enable reliable high-current transfer while providing dense insulation for high-voltage protection. Structurally, they offer impact resistance, vibration durability, and long-term mechanical stability, effectively replacing dispersed wiring to optimize space utilization and assembly efficiency. The insulation material must deliver excellent dielectric strength, high mechanical toughness, and long-term thermal stability, along with superior flowability for precise encapsulation of thin and complex geometries. Special formulations ensure strong copper–plastic bonding, preventing delamination and ensuring long-term reliability.

Click here to view the product video of this busbar.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Operating Temperature | Insulation Material | Conductor Material |

| Values | AC 1000V | Qualified | UL94 V-0 | -40 °C–120 °C (max 150 °C) |

PA66 + GF30 |

T2 Copper |

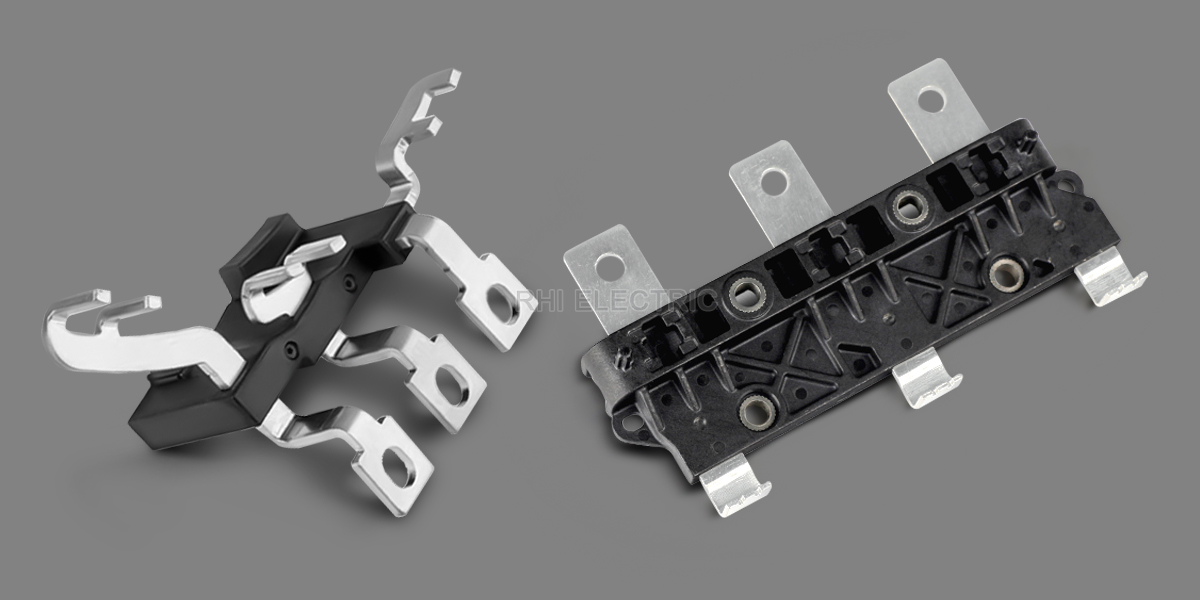

Core Functions and Design Advantages

- High-Voltage Conductivity: Made with high-purity copper conductors to ensure low resistance and excellent conductivity. Capable of stably transmitting hundreds of amperes within the battery pack’s high-voltage circuit, powering key units such as drive motors, BMS, and high-voltage relays.

- Reliable Electrical Insulation: The injection-molded insulation layer fully isolates the conductor from the environment, meeting IEC 60664 and ISO 6469 high-voltage safety standards. Insulated busbar prevents creepage, breakdown, and short-circuit risks, greatly enhancing system safety.

- Mechanical and Thermal Stability: The molded insulation offers high strength and vibration resistance, effectively absorbing assembly and operating shocks to prevent conductor fatigue, loosening, or breakage, ensuring long-term reliability.

- Compact Design and Assembly Efficiency: Replacing traditional wiring harnesses, the custom busbar integrates conduction, insulation, and mounting into a single structure, reducing components and assembly steps while optimizing space and routing within the battery pack.

- Automation Compatibility: With standardized geometry and high positioning accuracy, the structure supports automated assembly and inspection, improving production consistency and yield.