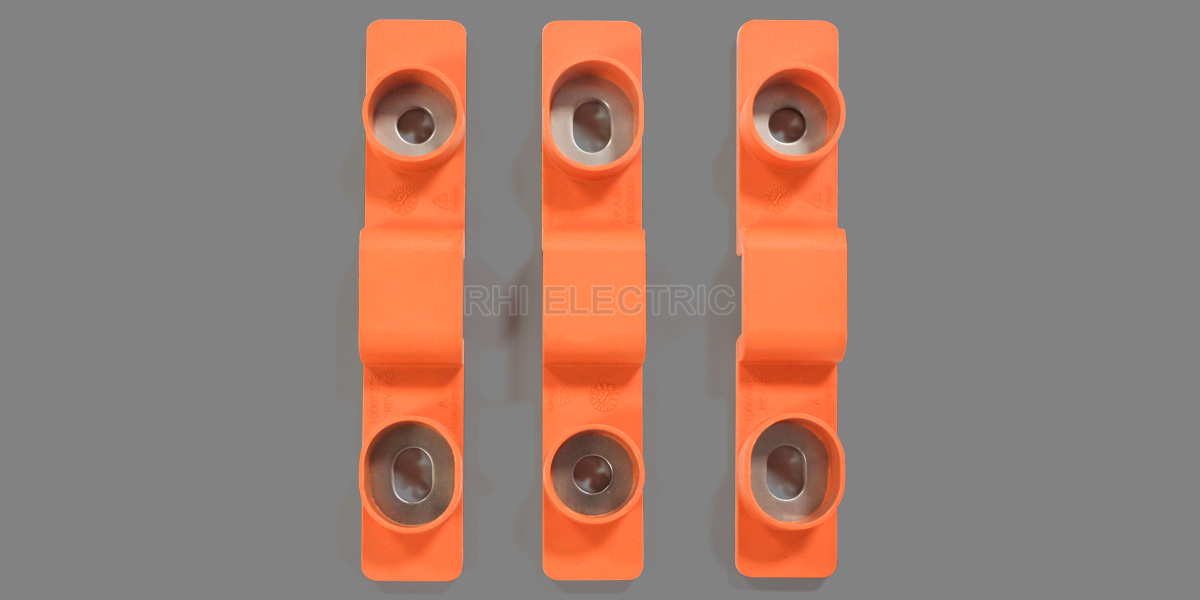

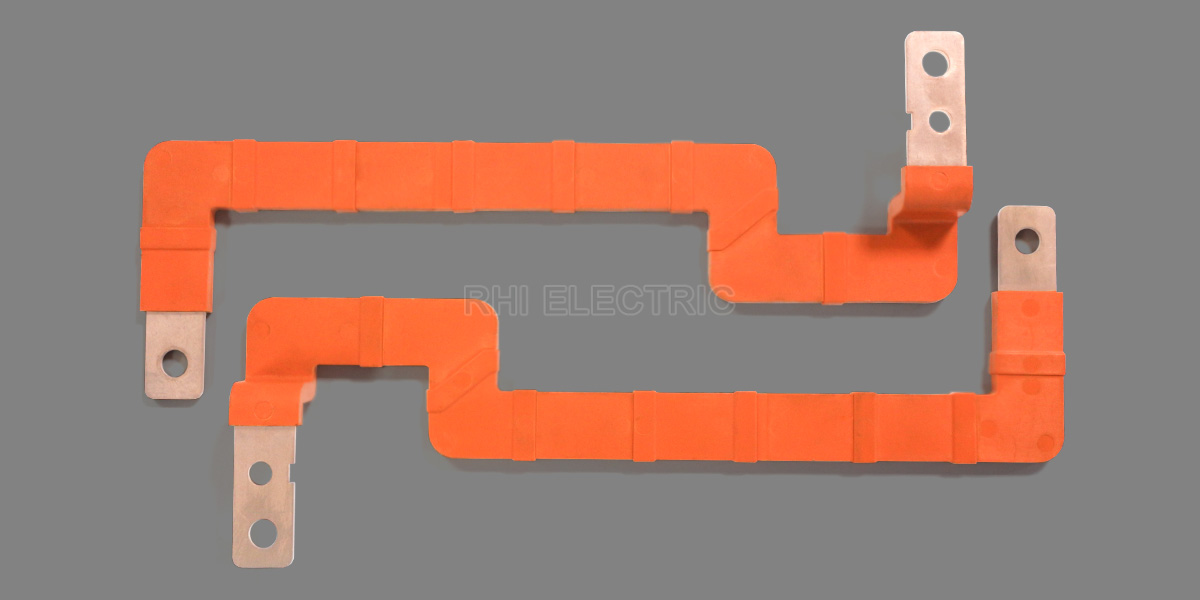

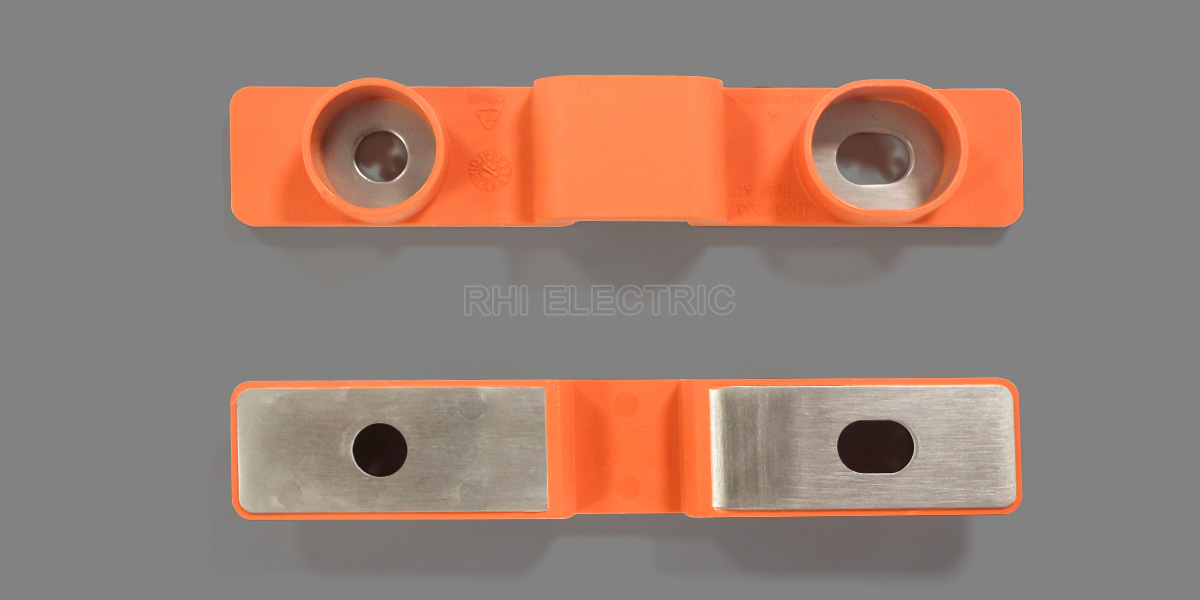

Copper Busbar Overmolded for EV Motor and Battery

This copper busbar is designed for new energy systems (battery, motor, ECU). It allows custom tooling, plating, and perforation. The PA66-GF30 insulation offers high mechanical strength, thermal resistance (HDT above 150 degrees Celsius), and processability. Featuring over 50% higher flexural strength, the HV busbar retains stable performance in harsh environments of high heat and vibration.

Electrical busbar features injection molding technology that seamlessly encapsulates the copper conductor, creating a void-free insulation layer. This design eliminates the risk of partial discharge and insulation degradation while providing excellent dielectric and mechanical strength. The insulated busbar ensures long-term reliability, even under demanding conditions of thermal cycling and mechanical vibration.

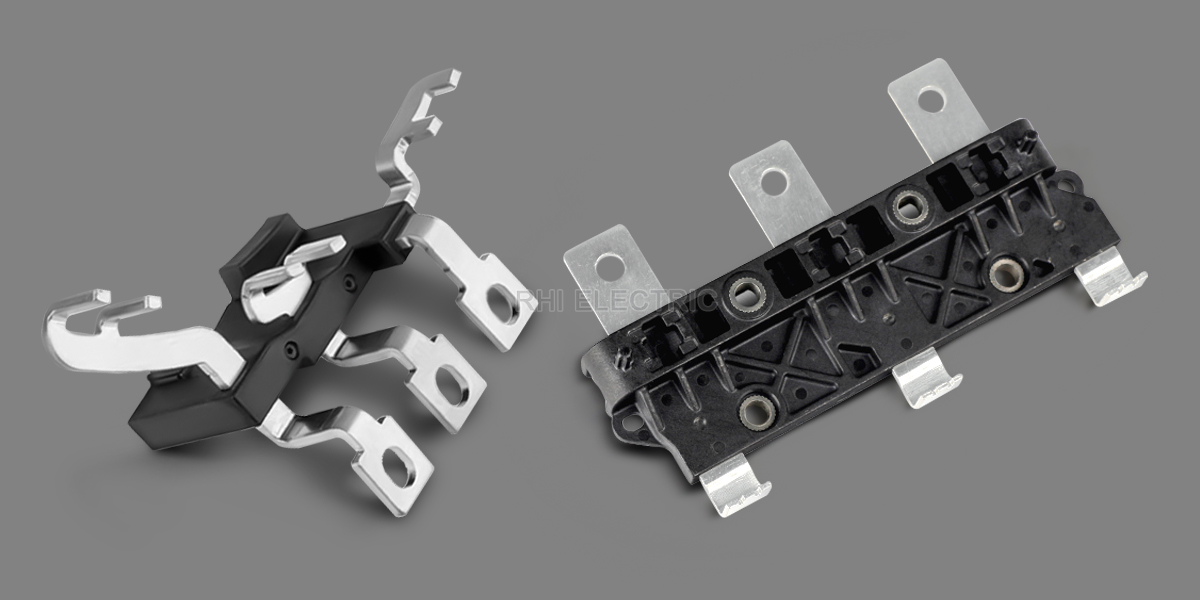

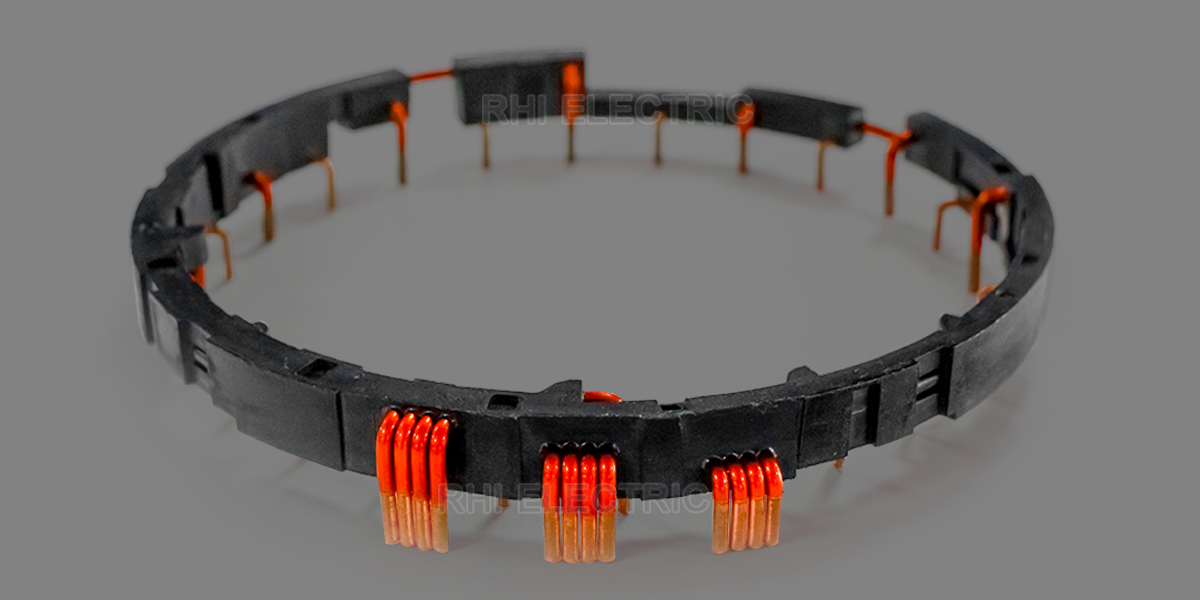

Engineered for high-voltage applications such as traction motors, controllers, and battery packs, the custom busbar enables more compact and power-dense systems without compromising safety under high voltage and current. Its robust design is suited for automated assembly and allows for flexible customization to meet various platform requirements, ultimately enhancing overall system safety and efficiency.

Click here to view the product video of this busbar.

| Parameter | Insulation Withstand Voltage | RoHS | Flammability Rating | Operating Temperature | Insulation Material | Conductor Material |

| Values | AC 1000V | Qualified | UL94 V-0 | -40 °C–120 °C (max 150 °C) |

PA66 + GF30 |

T2 Copper |

Performance Features

- Enhanced Mechanical Rigidity

PA66-GF30 insulation with 30% glass fiber reinforcement improves flexural strength by more than 50%, providing reliable performance in mechanically challenging applications. - Thermal Stability

With a heat deflection temperature ≥150°C, the busbar insulation maintains dimensional and functional integrity under prolonged high-temperature exposure. - Superior Moldability

The optimized flow properties of the material allow for thorough and uniform encapsulation of copper conductors during injection molding, ensuring consistent coverage. - Electrical Integrity

Vertical molding technology prevents the formation of interfacial gaps, enhancing dielectric strength and reducing the risk of partial discharge. - Environmental Durability

Mechanical and electrical properties remain stable under continuous thermal cycling and vibrational stress, supporting operation in demanding environments. - Adaptable Configuration

Customizable in dimensions and layout to accommodate specific integration needs across different vehicle and energy storage platforms.

Application Areas

- High-voltage interconnections for traction motors in electric vehicles

- Power transfer links between battery packs and motor controller

- Busbar systems for automated assembly in energy storage equipment